Ever wondered what it really costs to operate a waterjet cutting machine? This article breaks down the total expenses, including equipment depreciation, consumables, and labor, offering a comprehensive guide to understanding the hourly costs. Learn how these factors add up to impact your bottom line and utilize the provided calculator to estimate your own cutting costs accurately. Dive in to find out how to manage and optimize your expenses effectively.

Note:

The water-cutting cost mentioned in this article is calculated in China’s yuan (currency unit). You can replace the currency according to the actual situation, but the method of calculating the water-cutting cost is the same.

The average acquisition cost of a high-performance water jet cutting machine is estimated at 2.75 million yuan. This investment reflects the advanced technology and precision capabilities of modern water jet systems.

The expected service life of the equipment is 10 years, aligning with industry standards for heavy-duty industrial machinery.

The actual number of working days per year is 300, the average use time per day is 10 hours, and the accumulated working time in 10 years is 30,000 hours.

The average replacement cycle of important parts is 3,000 hours, and the cost is about 36,500 yuan.

The equipment purchase cost and replacement cost are (2.75 + 3.65 x 30,000 / 3,000 =) 31.15 million yuan.

Therefore, the equipment depreciation is about 103.8 yuan per hour.

| A: Vulnerable parts | Service life /consumption | Unit price (yuan) | Cost per hour (yuan) |

| Cylinder | 5000hr | 19872 | 3.97 |

| Head | 5000hr | 8567.5 | 1.71 |

| Valve components | 2000hr | 287.5 | 0.14 |

| Cushion and head | 2000hr | 394.6 | 0.19 |

| End part | 2000hr | 607.7 | 0.3 |

| Check spring | 2000hr | 23 | 0.01 |

| Drain valve assembly | 3000hr | 1939.10 /set | 0.64 |

| Hydraulic filter | 3000hr | 1093.6 | 0.36 |

| Piston guide ring | 3000hr | 284.5 | 0.09 |

| Sand knife tube | >150hr | 3000 | 20 |

| Sapphire nozzle | >100hr | 193.5 /piece | 1.94 |

| Diamond nozzle | >700hr | 6254.4 /piece | 8.93 |

| Nozzle tube | 70 hr | 524.7 | 7.49 |

| High-pressure sealing assembly | >700hr | 1166.8 /set | 1.66 |

| Needle valve | >70hr | 469.6 /set | 6.71 |

| Needle valve seat | 45 hr | 241.9 | 5.37 |

| Back pressure ring | 200hr | 133.3 | 0.66 |

| Piston seal assembly | >3000hr | 359.6 / set | 0.11 |

| Hydraulic seal assembly | >2000hr | 1927.9 /set | 0.96 |

| Hydraulic oil | 3000hr | 14500 / time | 4.83 |

| B: Materials, water and electricity | Service life /consumption | Unit price (yuan) | Cost per hour (yuan) |

| Water | <400kg/hr | 2.75 | 1.1 |

| Electric | <25kw/hr | 0.9 | 22.5 |

| Abrasive materials | <24kg/hr | 0.7 | 14.4 |

Total: 104.07 yuan/hour

There are 6 operators of the waterjet cutting machine, with a total monthly salary of 1800 yuan per person. In 10 years, it amounts to 1.296 million yuan.

Therefore, the labor cost per machine hour is 43.2 yuan.

The sum of all the above costs is the waterjet cutting cost, which is:

103.8 + 104.07 + 43.2 = 251.07 yuan per hour.

In other words, the actual waterjet cutting cost per hour is 251.07 yuan or around 35 US dollars.

Due to different material costs around the world, the final price may vary.

However, you can use the online water cutting cost calculator mentioned below for calculation.

To help you calculate water cutting cost more comprehensively, we have developed the following water cutting cost calculator. There are several points that require special attention:

The currency unit of the calculator is yuan. You can enter the amount in other currencies in the calculator without affecting the final result. However, you must keep all monetary units consistent.

The cost per hour of different consumables varies with the service life. You can refer to the table data in this article for calculation.

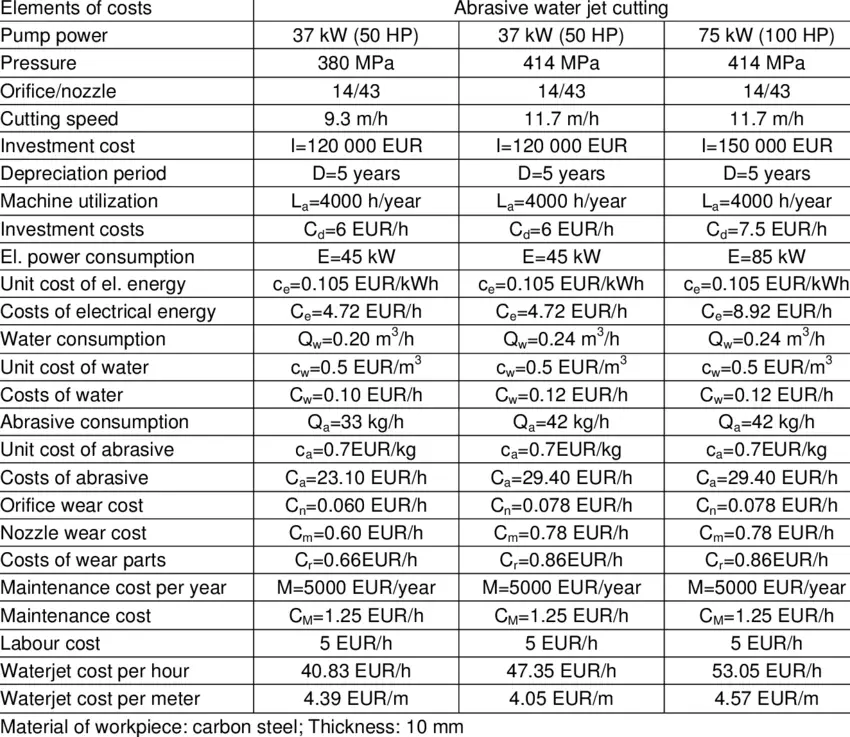

The following cost calculation example of abrasive waterjet cutting can also serve as a reference for calculating the cutting cost of a waterjet machine. It is based on cutting mild steel with a thickness of 10mm.