Welding copper with laser technology has revolutionized manufacturing, addressing challenges like copper’s low laser absorption and high thermal conductivity. This article explores how high-power fiber lasers produce stable, defect-free joints, crucial for industries such as consumer electronics and automotive. By mastering these techniques, manufacturers can achieve efficient, high-quality welds. Discover the specifics of laser types, absorption rates, and the benefits of dynamic beam control in welding copper. Dive into the technological advancements that are shaping the future of copper welding.

The consumer electronics and automotive industries play a crucial role in boosting the utilization of copper in industrial processing and product manufacturing.

As new battery technology with improved capacity is developed, the need for compatible connection technology also rises.

Despite soft soldering still being the primary technology for low-power consumer electronics applications, it must be employed in situations where high transmission current or high load and dynamic stress on joints are present.

This trend is particularly influenced by the electric vehicle industry and its suppliers, who seek robust and efficient processes for mass production operations such as power storage and line transmission.

In the past, the physical properties of copper and copper alloys limited the use of laser technology for welding.

However, the advent of high-power and high-brightness fiber lasers has overcome these limitations.

With the development of new and appropriate processing technology, stable and defect-free joints can be produced through an efficient welding process.

The difficulties in laser welding copper stem from two of its physical properties: low absorption of most high-power industrial lasers and high thermal conductivity during the process.

Copper’s absorption increases as the wavelength decreases, making visible band lasers, such as green lasers with a wavelength of 532 nm, well-suited for copper welding. However, these lasers are either not available or have not been thoroughly tested for the power range necessary for most welding applications.

Fig. 1: Defect-free copper welding through high-speed beam swing process

Infrared lasers face absorption issues when working with solid materials.

During deep penetration welding, if the material melts or evaporates, its absorption rate greatly increases.

The absorption rate of solid copper is less than 4%, but the absorption rate of copper vapor (generated during keyhole deep penetration welding) is over 60% (refer to the table below).

This absorption issue can be resolved by utilizing a very high power density, which accelerates the melting and evaporation of copper and therefore boosts its absorption.

Table: absorptivity of copper to near-infrared laser radiation under different states.

| State | Absorption rate (%) |

| Solid | 40 |

| Liquid | 10 |

| Keyhole penetration | >60 |

High-speed video analysis demonstrates that a stable process can be established in less than 1 millisecond.

For continuous wave (CW) welding, this challenge must be overcome at the start of the welding process. Once the keyhole welding process has been established, it provides a consistent high absorption rate. In pulse operation, this obstacle must be overcome at the beginning of each pulse.

The high power density necessary for welding can be achieved by using a single-mode fiber laser. This type of laser has superior beam quality and focusing performance compared to other solid-state lasers.

IPG offers high-power single-mode lasers up to 10 kW and high-brightness multi-mode lasers exceeding 10 kW, with solid and industrially tested designs.

By using these single-mode fiber lasers and low-order mode high-brightness lasers, intensities higher than 108W/cm² can be reached. Reliable coupling can be achieved even at power levels of hundreds of watts.

Compared to ordinary multi-mode lasers with the same power, the intensity of these lasers is up to 50 times greater.

IPG offers the YLR series of single-mode fiber lasers with a power range of 100W to 1000W, housed in a compact 19″ frame. The company also provides the YLS series of fiber lasers with power up to 10 kW (Figure 2).

The overall efficiency of both series is 40%.

Fig. 2: High power single-mode fiber laser: air cooled rack type YLR-1000-SM (left) and 3KW system type YLS-3000-SM (right).

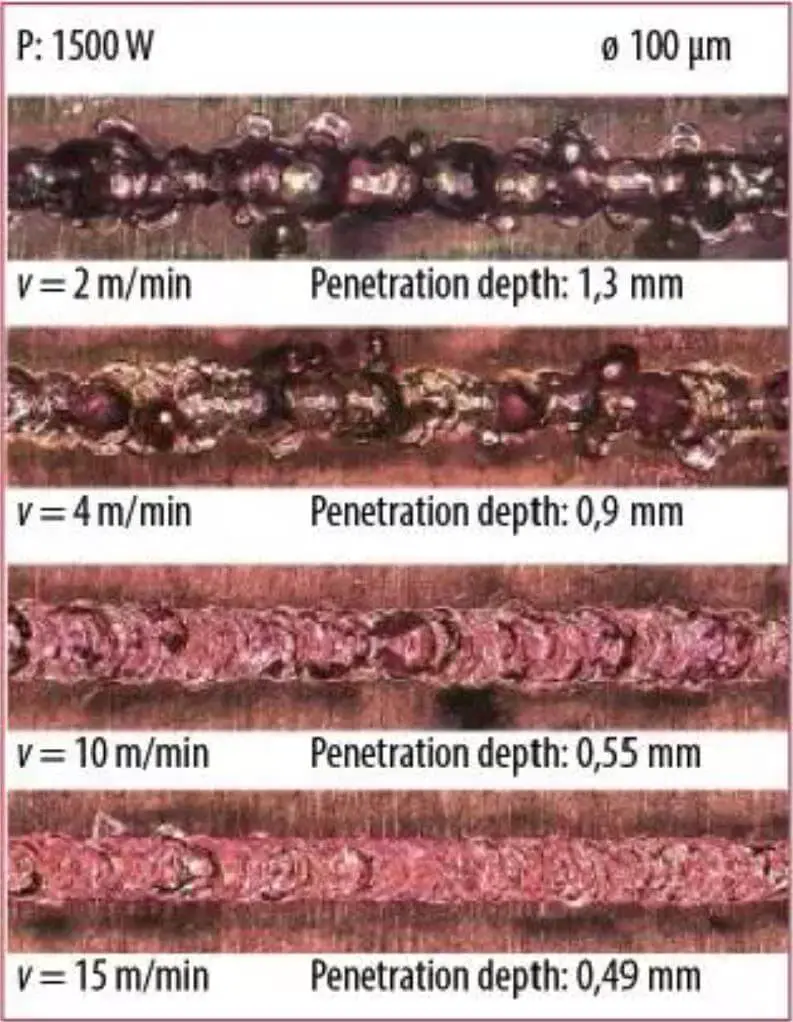

Another issue with the copper welding process is the instability that occurs at low welding speeds.

Typically, welding speeds below 5 meters per minute face instability problems such as spatter, porosity, and irregular weld surfaces.

However, as the welding speed increases, these instabilities gradually disappear.

At welding speeds between 5-15 meters per minute, the quality reaches an acceptable level.

If the welding speed exceeds 15 meters per minute, the resulting weld is largely free of defects (Figure 3).

This suggests that the optimal welding parameters fall within the capabilities of traditional motion systems, such as robots.

Fig. 3: Effect of processing speed on weld quality and weld depth.

New research has shown that process stability can be achieved not only by increasing the welding speed but also by dynamically changing the position of the beam-guiding lens.

This swinging technology allows for stable soldering joints to be formed at relatively low welding speeds and significantly reduces the weld depth.

Through this technology, a high-quality copper weld with a depth of up to 1.5mm can be achieved using only a single-mode fiber laser with a power of 1KW.

The same technology can be applied to high-brightness multi-mode lasers.

A 6kW fiber laser with a beam quality of 2 mm mrad was used in testing, and it was found that high-quality welding with a weld depth of 5mm could be achieved.

Fig. 4: FLW-D30 and FLW-D50 series swing welded joints launched by IPG

Dynamic beam control can be achieved through the use of a traditional scanning galvanometer or a new oscillating head, which combines the benefits of a proven welded joint and a scanning galvanometer.

These galvanometers can easily incorporate pre-programmed shapes such as circles, lines, or an “8-shape”, as well as freely programmable shapes within a certain size.

One of its key advantages is that it can use a standard focusing lens instead of an f-theta field mirror, and it can handle higher power density at a lower focus offset level.

Additionally, the use of a conventional transverse air curtain and protective window reduces the cost of consumables.

The FLW-D50 and FLW-D30 series of swing welding joints launched by IPG can operate at swing frequencies up to 1 kHz and can be seamlessly integrated into various processing systems (Figure 4). These welded joints can handle laser power up to 12 kW.

When welding a complex path with changing welding directions, circular swinging motion produces the best results.

The final beam velocity can be precisely controlled through the swing frequency and swing diameter (VC = πD f).

In most cases, the impact of the welding speed vector (VW) on the dynamic positioning of the circular beam speed (VC) is minimal, as the beam speed is much faster than the welding speed (VW).

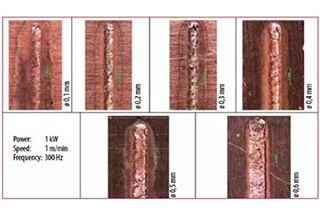

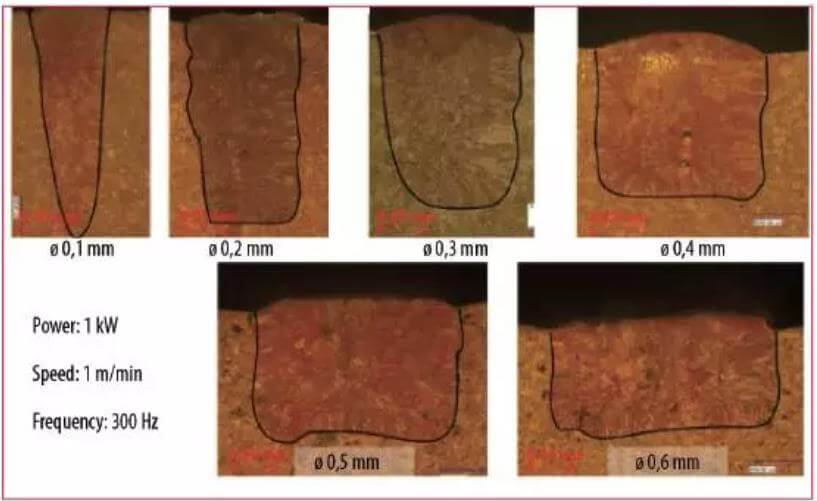

Fig. 5: Effect of swing amplitude on weld width and quality

The ideal frequency setting depends on the spot size, swing diameter (and resulting circular beam speed, VC), and linear welding speed.

Figure 5 illustrates the weld surface under constant laser power, frequency, and welding speed, but with varying swing diameters.

The spot size is approximately 30 μm at a focal length of 300mm. The laser power is kept constant at 1kW, and the linear welding speed is set to 1 meter per minute.

Without swing motion, these parameters would result in an unstable process, such as overheated molten pools and pores.

As the swing diameter increases and the circular beam velocity improves, the surface quality becomes increasingly stable.

Depending on the swing parameters and spot size, the beam and keyhole can move in either the metal bath or solid and re-solid materials, and the process can still achieve stability in both cases.

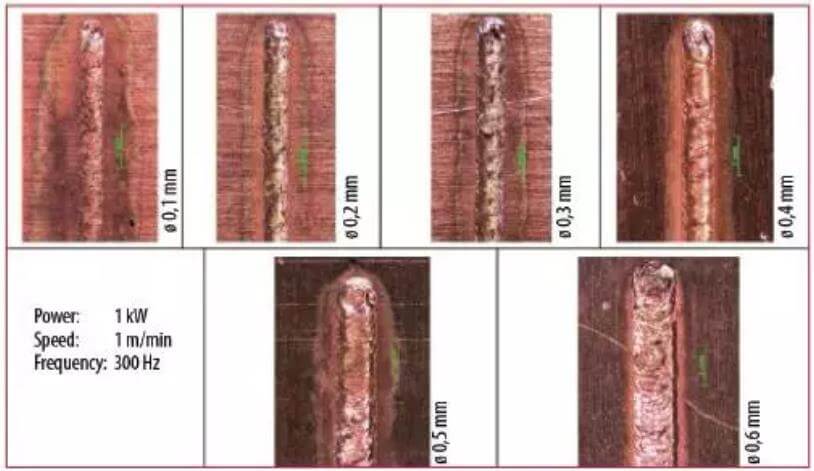

The cross-section of the weld shows another advantage of this technology: the swing diameter can be used to shape the cross-section of the weld.

A small swing diameter forms a typical V-shaped cross-section of laser welding, while a larger diameter can transform the weld from a V shape to a U shape or a regular rectangle (Figure 6).

Fig. 6: Effect of swing amplitude on weld cross section

When the energy input per unit length of the weld remains constant (E = P vw), the cross-section of the weld is nearly unchanged. This technology allows it to meet the specific cross-section requirements for various applications.

In the case of overlap welding for electrical contacts, the resistance can be decreased by increasing the contact area and properly controlling both the welding depth and heat input.

When welding dissimilar materials, such as copper and aluminum, the fusion ratio of the materials can be regulated by controlling the welding depth. By shallowly melting the lower metal plate, the amount of molten material can be kept to a minimum, and the formation of intermetallic compounds can be reduced by controlling the dilution ratio.

In recent years, long pulse fiber lasers with pulse durations of several milliseconds have been introduced to the market, replacing traditional flash lamp pumped Nd: YAG lasers in a wide range of applications. These lasers include single-mode lasers with an average power of 250W and a peak power of up to 2.5kW.

Earlier, the issue of pulse welding of copper was discussed. It is crucial to address the problem of weak absorption at the start of the pulse and the subsequent difficulties in controlling energy input due to sudden changes in absorptivity and heat conduction.

Using a single-mode laser to reduce the spot size can bypass the absorption problem, but at the same time, the concentrated energy input can result in small, weak solder joints and overheating of the melt.

The solution to this problem is simple and similar to the process used for continuous lasers. The same swing technology can be applied to quasi-continuous (QCW) lasers.

The high-frequency beam movement causes the laser beam to move a relatively long distance in a relatively short pulse time, effectively realizing quasi-continuous welding during one pulse. For example, a 20ms long pulse at a 600Hz swing frequency can produce circular solder joints or short wire welding composed of twelve rotating beams.

By adding pulses one by one to linear welds, high-quality copper welding can be achieved with low average power and a corresponding low investment cost. Solidification and remelting between pulses will not lead to welding defects such as pores, strong spatter, or uneven penetration depth.

The swing diameter determines the size and depth of the weld, and the heat input is much lower, making it easy to weld key electrical components with a pulsed fiber laser.

Experiments have shown that high brightness fiber lasers can effectively address all known problems in copper welding applications. The high power density of these lasers allows for the instantaneous formation of keyholes and ensures stability and high absorptivity, even at the wavelength of 1070nm.

Through dynamic beam swing, the welding process is highly stable, reducing or eliminating porosity and spatter to produce high-quality welds. The beam swing parameters can also be adjusted to control the welding geometry, resulting in shallow welds in deep penetration welding processes.

By using a long pulse quasi-continuous fiber laser, spot welding can be accomplished in a single pulse through the high-speed dynamic movement of the beam. By gradually increasing the number of pulses, high-quality welds can be achieved at a low average power.