Ever wondered how the integrity of welded nuts and screws in your car is ensured? This article reveals the meticulous process of quality checks and inspections that keep your vehicle safe and reliable. Learn how various tests and standards are applied to guarantee the strength and durability of these crucial components.

The tightening apparatus for weld nuts and weld screws necessitates assurance of quality during the installation process. Ensuring the integrity of these components is crucial to maintaining the overall reliability and safety of the assembled structure. To evaluate the weld quality and process reliability, it is essential to monitor the installation strength throughout the procedure. This continuous monitoring helps in detecting any deviations or anomalies that could compromise the weld’s integrity.

To further substantiate the reliability of the installation process, additional quality assurance measurements can be integrated into the production workflow. These measures may include real-time data collection and analysis, automated inspection systems, and statistical process control (SPC) techniques. By incorporating these advanced quality assurance methods, manufacturers can potentially obviate the need for subsequent inspections of weld nuts and weld screws, thereby streamlining the production process and ensuring consistent quality.

This standard document addresses the tightening of welded nuts and studs on steel plates and outlines the installation process for bolts. It details the welding installation conditions for the entire vehicle. Appropriate departments are responsible for these inspections. Methods not mentioned in the document should not be used.The manufacturing department requires process inspection. In the event of quality issues, the Quality Department can increase random inspections. For improvements in quality and system, and in response to quality issues, destructive testing of the vehicle frame is necessary.

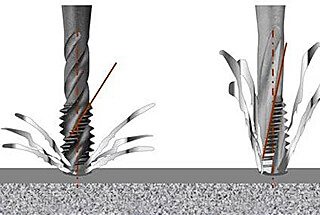

Boundary Weld: A joining weld is an incomplete fusion weld, where the stud merely adheres to the metal component without the required strength.

To control materials and cycles, all materials, methods, processes, parts, and systems should comply with the applicable legal specifications.

The following content can only be applied to steel plate welding.

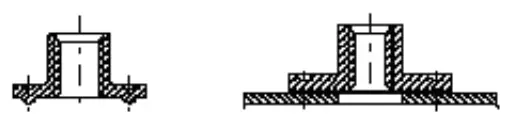

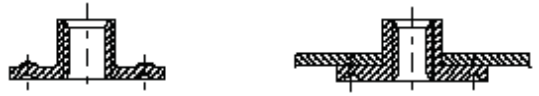

Steel Plate Nuts

Category A

Category B

Styles

Style A Style B

Weld Stud

Example: MBN 75 MBN 10391

All welds identified as defective through parameter monitoring (such as color marking) must be repaired. Additional test samples must be separated from the specified random test pieces being produced. Relevant process documents must be referred to when inspecting weld studs and weld nuts. The inspection department needs to record the inspection process in detail, including the methods used to identify defects in the test pieces.

Visual inspections must comply with established evaluation standards. These inspections should be conducted by trained inspectors under appropriate distance and lighting conditions to ensure accuracy and consistency.

Visual inspections must be meticulously recorded in a checklist. Any confirmed defects, such as weld points trending towards the edge, must be immediately addressed and corrected within the production system or welding equipment to prevent recurrence.

The inspection of weld nuts must adhere to the standards outlined in the table below. These standards ensure that all welds meet the required quality and safety criteria.

| Serial Number | Evaluation Criteria: | Example | |

| 1 | Missed welds of studs/nuts |  | |

| 2 | Damage or contamination of studs/nuts (including weld spatter and thread damage) |  | |

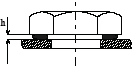

| 3 | The gap is inappropriate h > 0.1m |  |  |

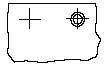

| 4 | Deviation from the center position Nuts must not obstruct the installation of bolts. |  | |

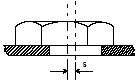

| Reference values: For nuts with M ≤ 5, S should be ≤ 1mm. For nuts with M ≥ 6, S should be ≤ 2mm. For arched round nuts, S should be < 0.8mm. | |||

By adhering to these standards, the quality and reliability of the welds can be maintained, ensuring the safety and performance of the final product.

Before conducting torque testing on welded nuts, an external inspection is mandatory. This inspection must adhere to the standards specified in section 7.2.3. The purpose of this inspection is to identify any visible defects or irregularities that might affect the integrity of the weld or the performance of the nut during torque testing.

Torque testing is a critical step to ensure the strength and reliability of welded nuts. The following steps outline the proper procedure:

The detailed standards and procedures for torque testing of welded nuts are provided in section 7.3.3. These standards outline the specific torque values, testing conditions, and acceptance criteria that must be met to ensure the welded nuts are fit for use.

| Torque Measurement | |

| M4 | 6 Nm |

| M5 | 8 Nm |

| M6 | 14 Nm |

| M8 | 32 Nm |

| M10 | 70 Nm |

| M12 | 100 Nm |

Note: Torque inspection must be conducted on square and hexagonal nuts, while the thickness of the steel plate need not be considered for arch-shaped and round nuts.

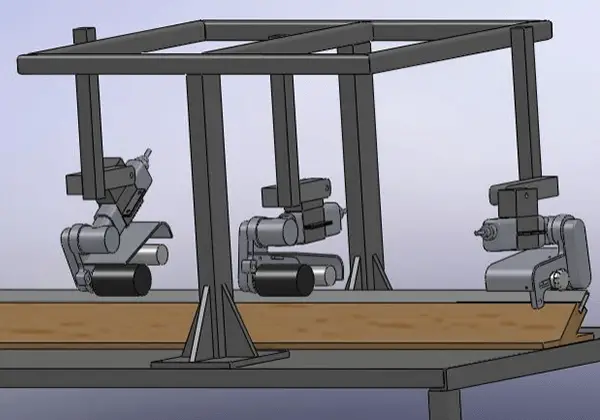

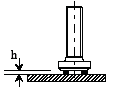

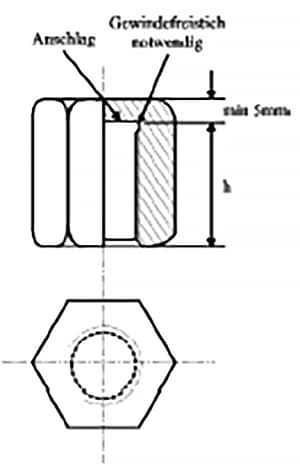

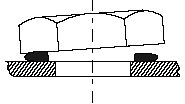

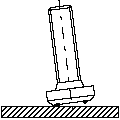

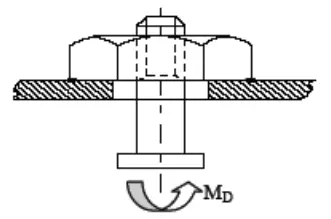

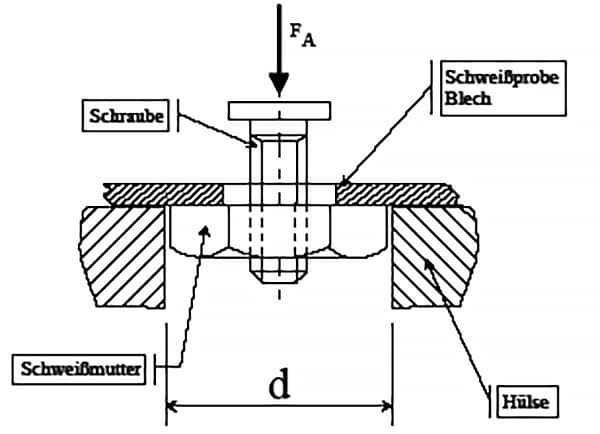

During the torque inspection process, first tighten the two nuts on the welding stud (as shown in Figure 1), then apply a predetermined Mtest inspection torque with a suitable torque wrench, thereby subjecting the nut to a torsional load (as shown in Figure 2).

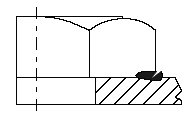

Subsequently, remove the two nuts. It’s plausible to employ an appropriate nut (as shown in Figure 3). Install the nut fully, then perform a torque check.

Following torque inspection, the installation of screws and nuts must be assessed based on the descriptions provided in the table below.

| Serial Number | Assessment Criteria | Example | |

| 1 | Screws or nuts must not be loose |  |  |

| 2 | Weld seams cannot exhibit separation |  |  |

| 3 | Weld seams must not be damaged (cracked) |  |

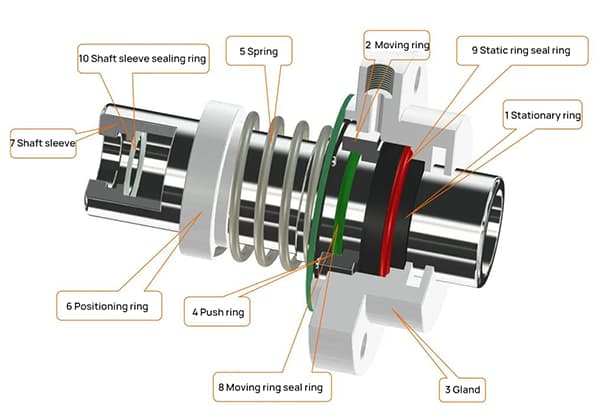

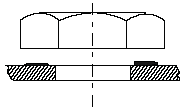

Before conducting torque tests on the circular nuts, visual inspections must be performed first as specified in section 7.2.3. Start by screwing a bolt into the circular nut using a torque wrench with an appropriate torque range.

During the test, the nut is subjected to a torque by the screw. If a crack appears at the seam before reaching the minimum torque, it is deemed insufficient in strength. The testing standard is in section 7.3.3.

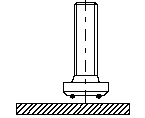

Before conducting torque tests, visual inspections need to be performed first as dictated in section 7.2.3. Begin by screwing a bolt into the ground nut using a torque wrench with an appropriate torque range.

During the test, the nut is subjected to a torque by the bolt. If a crack appears at the seam before reaching the minimum torque, the strength is deemed insufficient. The testing standard is in section 7.3.3.

For nuts installed in cavities that do not require regular testing, they can be tested using headless screws. Screw the headless bolt into the nut, and then use a torque wrench with an appropriate torque range to test the nut’s torque.

If a crack appears in the nut before reaching the minimum torque, the strength is deemed insufficient. The testing standard is in section 7.3.3.

| Torque Measurement | |

| M4 | 4 Nm |

| M5 | 5 Nm |

| M6 | 8 Nm |

| M8 | 20 Nm |

| M10 | 50 Nm |

| M12 | 80 Nm |

Note: Enhanced screws may be used if necessary.

Destructive testing is a specialized inspection method performed on vehicle frames to enhance quality and investigate quality issues. This type of testing involves intentionally damaging or destroying the component to assess its performance and integrity under stress.

Before conducting destructive testing on grounding nuts, a visual inspection must be performed as standardized in Section 7.3.3.

Destructive torque testing involves using a torque wrench with an appropriate torque range to determine the torque required to unscrew the nut. The minimum separation torque of the weld is listed in Table 6.6.

| Hexagonal Nut | Square Nut | Diameter (mm) | Plate Thickness (mm) | Length (mm) |

| M3 | 10 | 2 | 40 | |

| M4 | M4 | 12 | ||

| M5 | M5 | 13 | ||

| M6 | M6 | 14 | ||

| M8 | 18 | |||

| M8 | 21 | |||

| M10 | 23 | |||

| M12 | M10 | 27 | ||

| M14 | M12 | 31 | ||

| M16 | M14 | 33 |

For components not listed in the table, such as round screws or nuts, the inspection equipment must be similar to the above.

The components mentioned in section six.

| Thread Diameter | Plate Thickness | Compressive Force |

| M4 | 0.75 1.0 1.5 | >1.3kN |

| M5 | 0.75 1.0 1.5 | >2.0kN |

| M6 | 1.0 1.5 2.5 | >2.5kN |

| M8 | 1.0 2.0 3.0 | >3.0kN |

| M10 | 1.25 2.0 3.0 | >4.0kN |

| 7/16’’ | 1.25 2.0 3.0 | >5.0kN |

| M12 | 1.5 2.0 3.0 | >6.0kN |

Excessive pressure that extends beyond the scope needs to be agreed upon with the relevant responsible departments.

The peel test inspection is a crucial method for evaluating the integrity of welded steel plate nuts. This method involves peeling the nut off the steel plate using appropriate tools such as a hammer, chisel, or tension testing equipment. The objective is to ensure that the weld points maintain their dimensions and integrity post-welding.

In certain special cases, a metal cross-section inspection is utilized to assess the fastening state of bolts and nuts. This method provides a detailed view of the internal structure and integrity of the fastening.

As mentioned in Section 6, for the parts.

| Destructive Testing | Non-Destructive Testing | ||

| Thread Diameter | Plate Thickness | The torque setting in the welding system. | Monitoring the torque during the part inspection process, which is related to the thickness of the plate. |

| M4 | 0.7 1.25 1.5 | 13 Nm 13 Nm 16 Nm | 6 Nm 8 Nm 8 Nm |

| M5 | 0.7 1.25 1.5 | 20 Nm 29 Nm 29 Nm | 8 Nm 10 Nm 10 Nm |

| M6 | 0.8 1.5 2.0 | 24 Nm 33 Nm 34 Nm | 14 Nm 20 Nm 20 Nm |

| M8 | 1.0 2.0 3.0 | 58 Nm 61 Nm 60 Nm | 32 Nm 38 Nm 38 Nm |

| M107/16’’ | 1.25 2.0 3.0 | 112 Nm 133 Nm 125 Nm | 70 Nm 90 Nm 90 Nm |

| M12 | >1.5 | 140 Nm | 100 Nm |

Note: The inspection standard in 6.2.3 is specifically for thin steel plates.

The inspection of random samples must be recorded. The results of random inspections must be preserved for a specified period.

If defects are discovered during the inspection process, they must be immediately rectified. Additionally, the relevant systems must be inspected or corrected.

All vehicles currently experiencing the same issues must be repaired. Defective rivet nuts must be removed, and to secure new screws or nuts, the surface of the plate must be kept clean and flat.

For individual cases where screws and nuts cannot be replaced, suitable repair methods must be established through QPQ (Quench-Polish-Quench) and EP/CSV (Electropolishing/Chemical Surface Treatment).

The inspection department also needs to check the inspection tools.

The torque wrenches used must meet the following conditions:

Below are answers to some frequently asked questions:

The best practices for installing weld nuts involve careful preparation, precise welding techniques, and thorough testing to ensure a strong and reliable connection.

Firstly, select the appropriate type of weld nut and installation method. The two primary methods are projection welding and capacitive discharge welding. Projection welding is the most common, using nuts with projections that are heated by an electrical current until they collapse and fuse with the sheet metal. Capacitive discharge welding also uses an electrical current but is less common.

Proper positioning and surface preparation are crucial. Ensure the weld nut is aligned correctly with the hole in the sheet metal. The surface should be flat, clean, and free of debris to achieve a reliable weld. For nuts with projections, these should be in direct contact with the mating sheet metal.

During the welding process, the current must be sufficient to heat the projections to the welding temperature without causing metal expulsion. The electrode force should be adequate to bring the fastener into contact with the sheet metal without prematurely collapsing the projections. When welding inside a tube or enclosed space, use a wire welder, aiming through the hole to weld directly on the nut and avoid welding the hole itself. Ensure the tube or sheet metal is in a vertical position to use gravity to your advantage.

After welding, perform pull-through tests for critical applications to ensure the weld nut can withstand expected loads. Destructive testing on subassemblies may also be necessary to ensure quality.

Consider the material of both the nut and the sheet metal. Use nuts made from compatible materials, such as A307 or A563 grade A nuts, which are not heat-treated. The thickness and material of the sheet metal can influence the strength of the weld, with thicker sheets and materials like zinc-coated DP600 providing stronger welds.

In cases where welding is not feasible, consider alternatives like blind rivet nuts, which offer quick and simple installation without needing access to both sides of the material. Custom solutions using drilled, tapped, and welded nuts made from bar stock can also be considered for specific requirements.

By adhering to these best practices, you can ensure that weld nuts are installed correctly, providing a dependable fastening solution for various applications.

For the installation of weld nuts, several essential tools are required to ensure a strong and reliable bond. Key tools include:

Using these tools, along with proper techniques, ensures efficient and effective installation of weld nuts, resulting in a strong and reliable bond for various applications.

To ensure proper alignment during weld nut installation, several critical factors and techniques should be considered:

Firstly, the machine and electrode setup must be precise. The welding machine should be appropriately sized for the specific fastener being welded, and the welding conditions should fall within the machine’s normal operating range. The frame of the welding machine and the electrode assembly must be rigid to prevent flexure and misalignment under load. Ensuring that the electrode force is capable of holding each projection firmly against the stamping during the initial weld period is crucial, as it prevents metal expulsion before the parts come together.

Maintaining and aligning the electrodes is also essential. The surfaces of the electrodes must be flat, well-aligned, and free from oil, dirt, or film. The upper electrodes should be on the same centerline. Using Class 2 copper-alloy electrodes or harder tungsten-copper inserts can help minimize electrode wear. The weld pin of the lower electrode should be made from a properly insulated material, like ceramic, and should be spring- or air-loaded to assist in cooling the weld and expelling any weld spatter.

The design of the weld nut itself can greatly aid in alignment. Self-locating weld nuts, which feature an alignment collar, can prevent weld spatter from entering the thread area and self-align into standard hole sizes. Different designs, such as tab projection or hex 3 projection weld nuts, provide multiple projections that help achieve strong and reliable welds.

Preparation and installation are equally important. Accurate drilling of holes in the metal part to match the weld nut dimensions is necessary. Using a bolt turned down to the core diameter can help locate the nut in the hole and ensure concentric alignment. Cleanliness of the electrodes, sheet material, and weld nuts is vital; all components should be free from grease, rust, burrs, or other contaminants before installation.

During the welding procedure, it is important to follow the prescribed steps, considering the type of nut or stud, the size and location of the projections, and the thickness and material grade of the stamped part. Establishing the optimum weld schedule, including electrode force, weld time, and welding current, is key. Conducting destructive tests like push-off or peel tests can verify that the minimum specified torque is achieved with the selected parameters.

Lastly, troubleshooting common issues that can affect alignment and weld quality is essential. Problems such as high electrode force, low current levels, dirty panels or nuts, uncentered nuts, inconsistent pressure regulation, and incorrect weld times should be identified and addressed promptly.

By adhering to these guidelines, fabricators can minimize errors, ensuring successful and reliable weld nut installations.

When installing weld nuts, several common problems can arise, each with specific solutions to ensure successful and reliable welding.

One common issue is weld spatter and thread distortion. To avoid these, make sure the electrode surfaces are flat, well-aligned, and free from oil, dirt, or film. Using an air-supported pin in the lower electrode can help cool the weld and expel any weld spatter, preventing it from sticking to the guide pin and minimizing electrode-cap wear.

Cold welds are another frequent problem, occurring if the welding conditions are not properly set. Ensure the welding machine is correctly sized for the fastener being welded, and the required welding conditions fall within the normal operating range of the machine. The electrode force must hold each projection firmly against the stamping during the initial period of the weld time and have good follow-up characteristics when the projections collapse during the welding process.

Hole misalignment can be prevented by ensuring the upper electrode holds the fastener projections in place accurately to the stamped metal part. The frame of the welding machine and the electrode assembly must be rigid to avoid flexure and misalignment under load.

Heat treatment issues can arise when dealing with high-strength, heat-treated bolts and nuts, as rapid heat and cooling from tack welding can cause cracking or alter the material properties. To avoid this, use nuts that are not heat-treated, such as A307 or A563 grade A nuts. Alternatively, consider using materials like A36 bar stock or other prequalified materials that are suitable for welding.

Poor weld penetration, especially in spot-welded nuts, can lead to the nuts breaking loose over time. Ensure proper welding penetration by adjusting the welding parameters and using the correct electrode force. For existing poor welds, repairing or replacing the weld nuts might involve drilling new holes and using a wrench and nut on the back side, though this is less desirable due to the potential for frame damage.

By following proper setup guidelines, selecting appropriate materials, using correct welding techniques, conducting regular post-weld inspections, and being prepared for repair and replacement when necessary, fabricators can mitigate common problems associated with weld nut installation, ensuring reliable and high-quality welds.

When comparing Rivnuts and Plus Nuts to traditional weld nuts, several key factors need to be considered, including installation method, application suitability, strength, and ease of use.

Installation Method: Weld nuts are welded to another metal component using a welding machine. This process requires specialized equipment and ensures a strong, permanent bond. However, the welding process means that weld nuts are typically uncoated and may require subsequent plating or painting for corrosion protection.

Rivnuts (also known as blind rivet nuts) are installed using a hand tool or pneumatic tool and can be anchored entirely from one side. This makes them particularly useful for applications where access to both sides of the material is not possible. Rivnuts are inserted and then bulge on the back side as the fastener is tightened, locking the assembly into place.

Plus Nuts, while not explicitly detailed, generally function similarly to Rivnuts but may have specific design variations. The general principle of being inserted and then secured through a mechanical action (like bulging) applies.

Application Suitability: Weld nuts are ideal for applications requiring the strongest possible bond, especially in thin sheet metal or where high strength and durability are critical. They are often used in heavy-duty and critical applications where the integrity of the fastening is paramount.

Rivnuts are versatile and suitable for a wide range of materials, including sheet metal, laminated materials, and brittle substrates where regular hole tapping is not feasible. They are particularly useful in applications where access to both sides of the material is limited.

Strength and Durability: Weld nuts provide the strongest bond among the three options due to the welding process, which fuses the nut to the metal. This makes them suitable for high-stress and high-load applications.

Rivnuts, while strong, generally do not match the strength of weld nuts. However, they offer a reliable and secure fastening solution, especially in scenarios where welding is not feasible or practical.

Ease of Use and Cost: Weld nuts require specialized welding equipment and can be more labor-intensive to install. This increases the cost and complexity of the installation process. Additionally, weld nuts usually need to be coated or painted after installation to protect against corrosion.

Rivnuts are easier to install using hand tools or pneumatic tools, which are relatively less expensive compared to welding equipment. This makes Rivnuts a more accessible and cost-effective option for many applications.

Summary: Weld nuts offer the strongest bond and are suited for high-stress applications but require specialized equipment and are more labor-intensive and costly to install. Rivnuts, on the other hand, are easier to install, suitable for various materials and limited access scenarios, and are a more cost-effective and versatile solution, though they do not match the strength of weld nuts. When choosing between these options, consider the specific needs of your application, including the required strength, ease of installation, and the materials involved.