What makes welding low-carbon quenched and tempered steel so challenging? This article explores the intricacies involved, from managing cold cracks to preventing embrittlement in the heat-affected zone. You’ll learn key techniques and precautions to ensure strong, reliable welds on high-strength steel. Dive in to understand the essential practices for welding this specialized material and ensure your projects meet the highest standards of safety and durability.

As high-strength welding structural steel, the carbon content of this type of steel is limited to a low level.

Generally, the mass fraction of carbon is less than 0.18%, and the weldability requirements are also considered in the design of alloy composition.

Therefore, the welding of low-carbon quenched and tempered steel is basically similar to that of normalized steel.

The following problems mainly occur during welding:

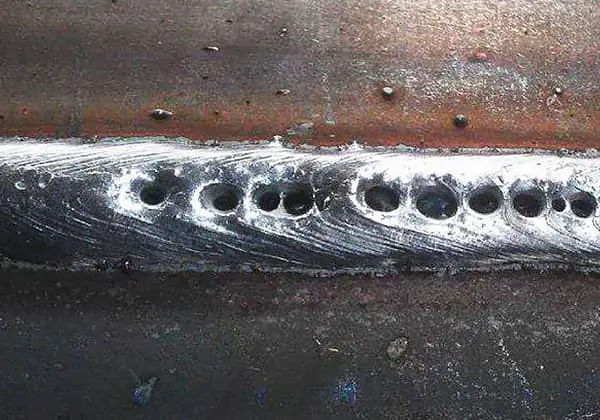

Low carbon quenched and tempered steel generally has low carbon content, high manganese content and strict control over S and P, so the hot cracking tendency is small.

However, high nickel low manganese type low alloy high strength steel will increase the tendency of hot cracking and liquefaction cracking.

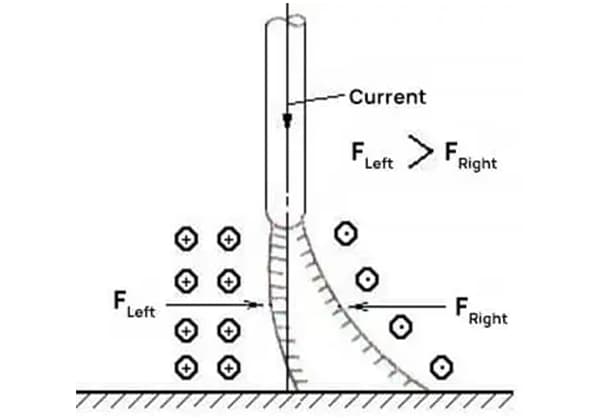

Because this kind of steel contains more alloy elements that can improve the hardenability, it has a great tendency of cold cracking.

However, due to the high Ms point of this type of steel, if the joint can be cooled slowly at this temperature, the generated martensite can be subject to a “self tempering” treatment, which reduces the cold cracking tendency to a certain extent, so the cold cracking tendency is not necessarily great in fact.

Low carbon quenched and tempered steel contains strong carbide forming elements such as V, Mo, Nb, Cr, etc., so it has a certain tendency to reheat crack.

Softening occurs in the area from the original tempering temperature of the base metal to Ac1 during welding.

The lower the original tempering temperature, the larger the softening range and the more serious the softening degree.

If low carbon martensite and lower bainite with volume fraction of 10% – 30% are produced in the superheat zone, high toughness can be obtained.

However, when the cooling rate is too fast, the low carbon martensite with volume fraction of 100% is formed, and the toughness will decrease;

When the cooling rate is too slow, on the one hand, the grains will be coarsened, on the other hand, the mixed structure of low-carbon martensite and bainite plus M-A components will be generated in the superheat zone, which will cause more serious embrittlement in the superheat zone.

When welding quenched and tempered steel with σs ≥ 980MPa, welding methods such as argon tungsten arc welding or electron beam welding must be used.

For low carbon quenched and tempered steel with σs<980MPa, it can be used for shielded metal arc welding, automatic submerged arc welding, gas metal arc welding and argon tungsten arc welding.

But for steel with σs ≥ 686MPa, gas metal arc welding is the most appropriate automatic welding process.

In addition, if welding methods with large heat input and low cooling rate such as multi wire submerged arc welding and electroslag welding must be adopted, post-welding quenching and tempering treatment must be carried out.

When the heat input is increased to the maximum allowable value and the crack cannot be avoided, preheating measures must be taken.

For low-carbon quenched and tempered steel, the purpose of preheating is mainly to prevent cold cracks, and preheating may have adverse effects on toughness, so generally, lower preheating temperature (≤ 200 ℃) is used when welding low-carbon quenched and tempered steel.

Preheating is mainly hoped to reduce the cooling rate during martensite transformation, and improve the crack resistance through self tempering of martensite.

When the preheating temperature is too high, it is not necessary to prevent cold, but it will make the cooling rate of 800-500 ℃ lower than the critical cooling rate for brittle mixed structure and make the heat affected zone appear obvious embrittlement.

Therefore, it is necessary to avoid blindly increasing the preheating temperature, including the interpass temperature.

Low carbon quenched and tempered steel is generally not subject to heat treatment after welding.

Therefore, when selecting welding materials, it is required that the weld metal obtained shall have mechanical properties close to the base metal in the as welded state.

In special cases, such as the high stiffness of the structure and the difficulty of avoiding cold cracks, materials with slightly lower strength than the base metal must be selected as the filler metal.