Why do thin stainless steel plates warp during welding? This article explores the causes of welding deformation, focusing on the impact of various welding methods and techniques. It discusses how factors like heat input, welding sequence, and tack welding can influence the final shape of thin plates. By understanding these elements, you can effectively minimize deformation, ensuring better quality and precision in your welding projects.

In welding processes involving stainless steel thin plates, they are prone to warping, which can be attributed to various factors. To control the distortion during welding, it is essential to first understand the impact of different welding methods on the deformation.

Related reading: How to Fix Stainless Steel Welding Deformation?

The majority of welding techniques take into account both production efficiency and welding quality.

As a result, the welding method, process, and procedure can significantly affect the level of deformation.

Therefore, the chosen welding method should possess high deposition efficiency and as few welding passes as possible.

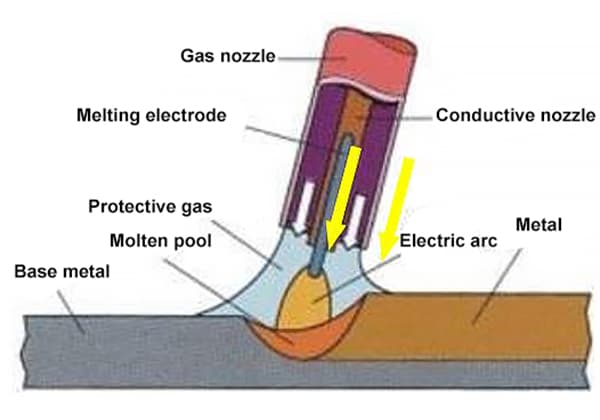

Additionally, the heat input should be minimized. Commonly used methods for welding stainless steel thin plates include single-sided submerged arc welding, double-sided submerged arc welding, flux-cored wire arc welding, inert gas shielded welding, and active gas shielded welding.

The industry widely recognizes the influence of welding heat input on residual stress and deformation.

Therefore, while ensuring good weld formation, it is crucial to use the smallest possible welding heat input to minimize stress and deformation.

Controlling the welding heat input involves the appropriate selection of welding current, voltage, and speed. For TIME welding, the proportion of ternary or quaternary shielding gases must also be considered.

As the thickness of the stainless steel plate decreases, its resistance to bending deformation decreases, making it more challenging to control deformation in stainless steel thin plate welding.

Moreover, quality control for stainless steel thin plate welding deformation includes the entire process from cutting the stainless steel plate to clamping, tack welding, welding, and post-weld treatment.

The chosen welding method and effective deformation control measures should be taken into account. The impact of cutting methods and cutting quality on thin plate welding deformation is smaller for laser cutting than plasma cutting due to its concentrated heat source and fast cutting speed.

The cutting accuracy significantly influences the assurance of the welding gap. Plasma cutting may cause uneven edges, resulting in bulging after tack welding, while laser-cut plates maintain a relatively smooth surface after tack welding.

Tack welding not only ensures the welding gap but also provides some resistance to deformation. However, it is necessary to consider the number, size, and spacing of the tack welds.

For stainless steel thin plate deformation, tack welding is not suitable if substantial residual welding stress may occur before welding, which could affect the subsequent accumulation of residual stress.

Insufficient tack weld size may lead to cracking during welding, compromising the welding gap assurance, while excessive tack weld size may cause incomplete penetration on the weld bead’s backside, affecting the joint’s integrity.

The sequence and reasonable selection of tack weld distances are also crucial, and their impact has been described in numerous publications.

Assembly stress and welding procedures should minimize stress caused during the welding assembly process. If the stress exceeds the critical stress causing deformation, distortion may occur. Different welding procedures have varying effects on residual stress.