Ever wondered what those numbers and letters on welding rods mean? This article demystifies the coding system for carbon and stainless steel welding rods, helping you understand their tensile strength, welding positions, and coating types. Get ready to enhance your welding knowledge and make informed choices for your projects!

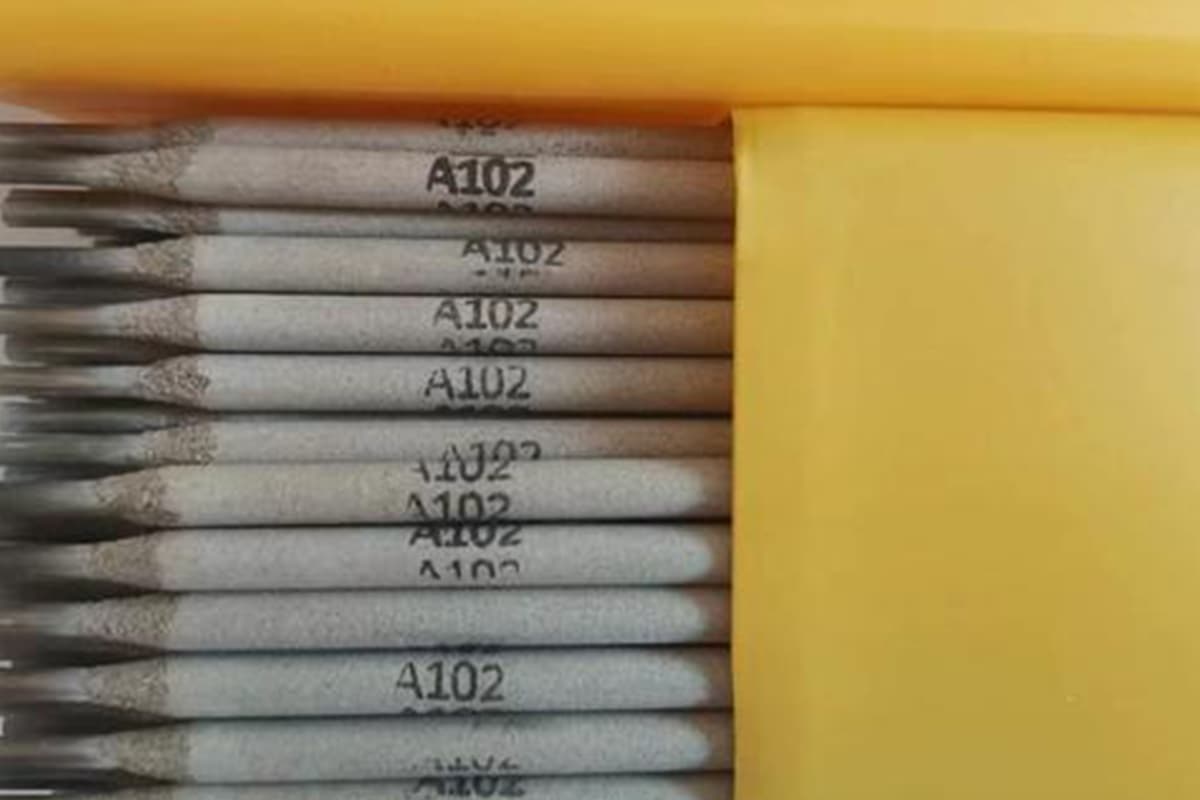

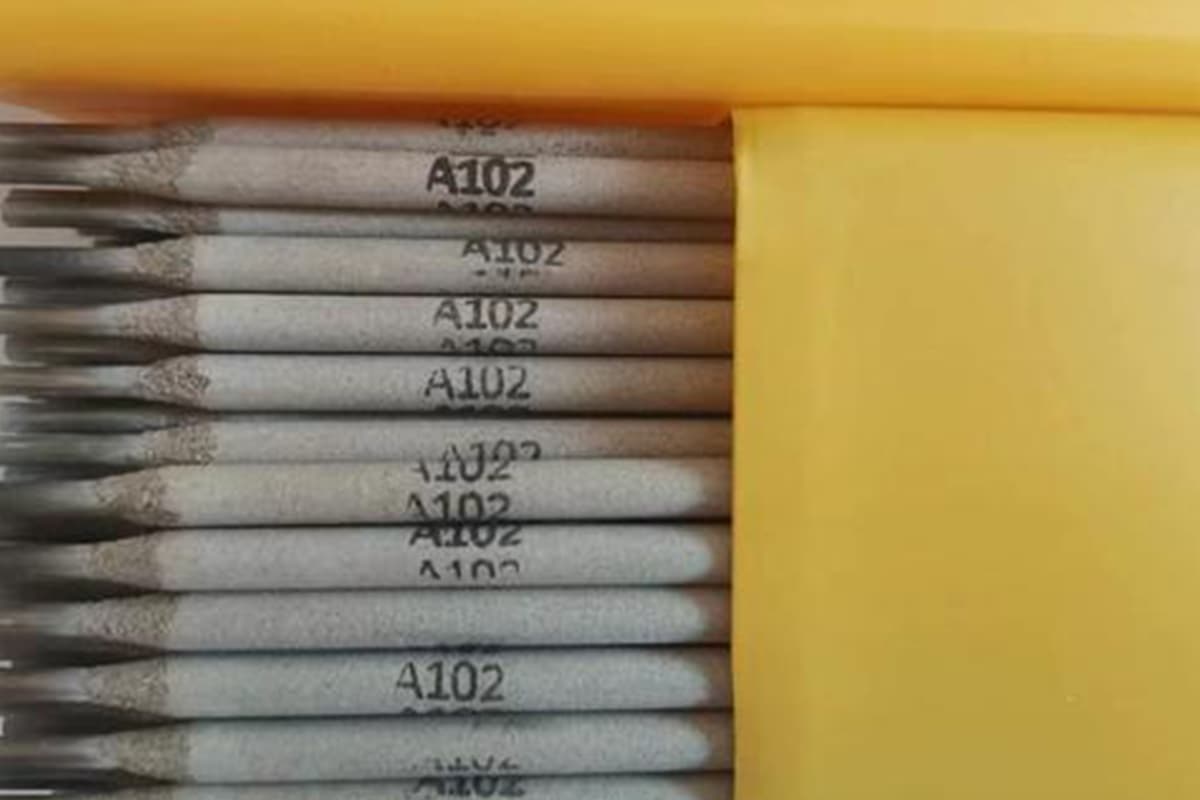

Welding rods, also known as electrodes, are essential components in the welding process. They serve as the filler material that joins two or more pieces of metal together, and their performance can significantly impact the quality and durability of the weld. Understanding welding rod grades is crucial for anyone involved in welding, whether you are a seasoned professional or a beginner.

Welding rod grades are classifications that indicate the characteristics and capabilities of each rod. These grades help welders select the appropriate rod based on the specific requirements of their projects. Factors such as tensile strength, welding position, and the type of coating are all considered in these classifications, making it easier for welders to choose the right rod for their needs.

The American Welding Society (AWS) has established a standardized numbering system to classify welding rods. Each rod is identified by a series of numbers and letters that convey critical details regarding its properties. For example, the classification code E7018 can be broken down as follows:

This system allows welders to quickly assess the suitability of a rod for their specific application.

The classification and numbering system for welding rods, especially those used in Shielded Metal Arc Welding (SMAW), is standardized by the American Welding Society (AWS). This system provides essential information about the welding rod’s properties, aiding welders in selecting the appropriate rod for their specific tasks.

The classification code of a welding rod typically starts with the prefix “E,” indicating it is an electrode. The digits following this prefix convey critical information about the welding rod’s tensile strength and application.

The next-to-last digit specifies the positions in which the electrode can be used.

The last digit provides details about the type of flux coating and the rod’s specific characteristics. Flux coating affects the rod’s performance, including penetration, spatter, and the type of current it can use.

Some electrodes come with additional designators that provide more specific information about their performance characteristics and suitability for certain applications.

Understanding the classification and numbering system helps welders choose the right electrode for their needs. Here are some common electrodes and their characteristics:

By understanding this classification and numbering system, welders can ensure optimal performance and weld quality by selecting the appropriate welding rod for their specific applications.

| No. | Grade | Model | ||||

| GB | AWS | JIS | DIN | |||

| E43 Series – Tensile Strength of Deposited Metal≥420Mpa(43kgf/mm2) | ||||||

| 1 | CHE40 | J421 | E4313 | E6013 | D4313 | E4332 R3 |

| 2 | CHE420T | J420G | E4300 | |||

| 3 | CHE421 | J421 | E4313 | E6013 | D4313 | E4332 R3 |

| 4 | CHE421Fe16 | J421Fe16 | E4324 | E6024 | ||

| 5 | CHE421Fe18 | J421Fe18 | E4324 | E6024 | ||

| 6 | CHE421D | J421X | E4313 | E6010 | D4313 | E4333R (C) 3 |

| 7 | CHE42 | J422 | E4303 | E6019 | D4303 | |

| 8 | CHE422 | J422 | E4303 | D4303 | ||

| 9 | CHE423 | J423 | E4301 | D4301 | ||

| 10 | CHE424 | J424 | E4320 | E6020 | D4320 | E4354AR11160 |

| 11 | CHE424Fe16 | J424Fe16 | E4327 | E6027 | D4327 | E4354AR11160 |

| 12 | CHE425 | J425 | E4311 | E6011 | D4311 | |

| 13 | CHE425G | J425G | E4310 | E6010 | ||

| 14 | CHE425GX | J425G | E4310 | E6010 | E4343C4 | |

| 15 | CHE426 | J426 | E4316 | E6016 | D4316 | E4343B10 |

| 16 | CHE47 | J427 | E4315 | |||

| 17 | CHE427 | J427 | E4315 | |||

| 18 | CHE427T | J427X | E4315 | |||

| E50 Series – Tensile Strength of Deposited Metal≥490Mpa(50kgf/mm2) | ||||||

| 1 | CHE501Fe | J501Fe | E5014 | E7014 | E4321AR11120 | |

| 2 | CHE501Fe16 | J501Fe16 | E5024 | E7024 | E5142RR11160 | |

| 3 | CHE502 | J502 | E5003 | D5003 | ||

| 4 | CHE503 | J503 | E5001 | |||

| 5 | CHE505 | J505 | E5011 | E7011-A1 | ||

| 6 | CHE505G | E5010 | E7010-A1 | |||

| 7 | CHE505GX | E5010 | E7010-A1 | |||

| 8 | CHE56 | J506 | E5016 | E7016 | D5016 | E5154B (R) 10 |

| 9 | CHE506 | J506 | E5016 | E7016 | D5016 | E51431310 |

| 10 | CHE50 | J507 | E5015 | E7015 | ||

| 11 | CHE507 | J507 | E5015 | E7015 | E51551310 | |

| 12 | CHE507T | J507X | E5015 | E7015 | E51551310 | |

| 13 | CHE507Fe16 | J507Fe16 | E5028 | E7028 | D5026 | E5155B (R) /2160 |

| 14 | CHE58-1 | E5018-1 | E7018-1 | D5016 | E5154B (R) 10 | |

| 15 | CHE508-1 | E5018-1 | E7018-1 | E5154B10 | ||

| 16 | CHE508 | E5018 | E7018 | D5016 | E5153B10 | |

| 17 | CHE508T | E5048 | E7048 | |||

Please refer to: GB/T 5117-1995 “Carbon Steel Electrodes for Shielded Metal Arc Welding.

Comparison of Old and New Designations for Commonly Used Carbon Steel Welding Rods and Their Applicable Scope:

| National Standards GB980-77 | National Standards GB5117-95 | Using Power Supply | Drying Temperature and Time (℃×h) | Suitable for welding steel materials. |

| J421 | E4320 | Direct Connection of Alternating or Direct Current | 150—200×1 | Flat welding and angle welding of A3, Q235A, Q235F, 10, 20 steel |

| J422 | E4303 | Direct Connection of Alternating or Direct Current | 150—200×1 | A3, Q235A, Q235F, 10, 20 |

| J423 | E4301 | Direct Connection of Alternating or Direct Current | 150—200×1 | A3, Q235A, Q235F, 10, 20 |

| J427 | E4315 | Reverse Connection of Direct Current | 350—400×2 | Q235B, C, D, 20R, 20g |

| J502 | E5003 | Direct Connection of Alternating or Direct Current | 150—200×1 | Q295, Q345, 16Mn, etc. |

| J506 | E5016 | Reverse Connection of Direct Current or Alternating Current | 350—400×2 | Q295, Q345, 16Mn, 16MnR, etc. |

| J507 | E5015 | Reverse Connection of Direct Current | 350—400×2 | Q295, Q345, 16Mn, 16MnR, etc. |

Low Alloy Steel Welding Rod:

| No | Grade | GB | AWS | JIS | DIN | |

| 1 | CHE502WCu | J502Wcu | TBE5003-G | |||

| 2 | CHE505Mo | E5010-A1 | E7010-A1 | |||

| 3 | CHE506NiLH | E5016-G | E7016-G | |||

| 4 | CHE506WCu | J506Wcu | TBE5016-G | |||

| 5 | CHE507NiLH | E5015-G | E7015-G | |||

| 6 | CHE507RH | E5015-G | ||||

| 7 | CHE507CuP | J507CuP | E5015-G | E7015-G | ||

| 8 | CHE507MnMo | E5015-G | E7015-G | |||

| 9 | CHE507CrNi | J507CrNi | E5015-G | E7015-G | ||

| 10 | CHE507GX | |||||

| 11 | CHE508Ni | E5018-G | E7018-G | |||

| 12 | CHE555GX | E5510-G | E8010-P1 | |||

| 13 | CHE557 | J557 | E5515-G | E8015-G | D5316 | EY5066NiMoBH5 |

| 14 | CHE557MoV | J557MoV | E5515-G | E8015-G | D5316 | EY5066NiMoBH5 |

| 15 | CHE557GX | |||||

| 16 | CHE558GX | |||||

| 17 | CHE62CFLH | E6015-G | E9015-G | D5816 | E55548XXH5 | |

| 18 | CHE606 | J606 | E6016-D1 | E9016-G | D5816 | E55548XXH5 |

| 19 | CHE607 | J607 | E6015-D1 | E9015-G | D5816 | DY5554BXXH5 |

| 20 | CHE607Ni | J607Ni | E6015-G | E9015-G | D5816 | EY5554BXXH5 |

| 21 | CHE607GX | |||||

| 22 | CHE707 | J707 | E7015-D2 | E10015-G | D7016 | EY624BXXH5 |

| 23 | CHE707MnMo | E7015-G | E10015-G | D7016 | EY624BXXH5 | |

| 24 | CHE707Ni | J707Ni | E7515-G | E10015-G | D7016 | EY624BXXH5 |

| 25 | CHE757 | J757 | E7517-G | E11015-G | D7016 | EY6924BXXH15 |

| 26 | CHE758 | E7518-G | E11018-G | |||

| 27 | CHE80C | E8015-G | E12015-G | |||

| 28 | CHE857 | J857 | E8515-G | E12015-G | EY7953BXXH15 | |

| 29 | CHE857Cr | J857Cr | E8515-G | E12015-G | EY7953BXXH15 | |

| 30 | CHE857CrNi | J857CrNi | E8515-G | E12015-G | EY7953BXXH15 | |

| 31 | CHE858 | E8518-G | E12018-G | |||

| 32 | CHH107 | R107 | E5015-A1 | E7015-A1 | DT1216 | EMoB10+ |

| 33 | CHH108 | E5018-A1 | E7018-A1 | |||

| 34 | CHH202 | R202 | E5503-B1 | |||

| 35 | CHH207 | R207 | E5518-B1 | E8015-B1 | ||

| 36 | CHH307 | R307 | E5515-B2 | E8015-B2 | DT2315 | ECrMolB10+ |

| 37 | CHH308 | E5515-B2 | E8018-B2 | |||

| 38 | CHH317 | R317 | E5515-B2-V | E8016-B2 | DT2315 | |

| 39 | CHH327 | R327 | E5515-B2-VW | |||

| 40 | CHH337 | R337 | E5515-B2-VNb | |||

| 41 | CHH347 | R347 | E5515-B3-VWB | |||

| 42 | CHH347A | |||||

| 43 | CHH407 | R407 | E6015-B3 | E9015-B3 | DT2415 | EcCrMo2B10+ |

| 44 | CHH417 | R417 | E5515-B3-VNb | |||

| 45 | HL107 | W107 | E5015-C2L | E7015-C2L | ||

| 46 | HL707 | W707 | E5515-Cl | E8015-C1 | ||

| 47 | HL907 | E7015-G | ||||

Comparison of old and new model numbers of alloy steel welding rods, and their application scope:

| National Standards GB982-77 | National Standards GB5118-95 | Drying | Suitable for welding steel materials. |

| R102 | E5003-A1 | 150~200℃×1 h | Preheat 15Mo to 90-110°C, then temper at 605-635°C. |

| R107 | 350℃×1 h | ||

| R202 | E5503-B1 | 150~200℃×1 h | Preheat 12CrMo to 150-200°C, then temper at 605-635°C. |

| R207 | 350℃×1 h | ||

| R302 | E5503-B2 | 150~200℃×1 h | Preheat 15CrMo at 160-200℃, temper at 675-705℃. |

| R307 | E5515-B2 | 350℃×1 h | |

| R312 | E5503-B2-V | 200℃×1 h | Preheat 12CrMoV at 250-300℃, temper at 715-745℃. |

| R317 | E5515-B2-V | 350℃×1 h | |

| R327 | E5515-B2-VW | Preheat 15CrMoV to 250-300℃, then temper at 715-745℃. | |

| R337 | E5515-B2-VNb | ||

| R402 | E6003-B3 | 200℃×1 h | Preheat 12Cr2Mo at 160-200℃, temper at 675-705℃. |

| R407 | E6015-B3 | 350℃×1 h | |

| R417 | E5515-B3-VNb | Preheat 12Cr3Mo3SiTiB at 200-300℃, then temper at 715-745℃. | |

| R507 | E15MoV-15 | Cr5Mo should be preheated at 300 to 400 degrees Celsius, followed by tempering treatment at 740 to 760 degrees Celsius. | |

| R707 | E9Mo-15 | Cr5Mo should be preheated at 300 to 400℃, and then tempered at 730 to 750℃. | |

| R802 | E11MoVNi-16 | 1Cr11MoV should be preheated at 300-400°C, then tempered at 730-750°C. | |

| R807 | E11MoVNi-15 | ||

| R817 | E11MoVNiW-15 | Cr11MoNiVW should be preheated at 350-450℃, and then undergo tempering treatment at 730-750℃. | |

| R827 | Cr11MoNiV; Preheat Cr11MoV at 350 to 450℃, then temper at 730 to 750℃. |

Description: E5003-A1 – Carbon Molybdenum Steel; E5503-B1, B2, B3 – Increased Chromium content, Chromium Molybdenum Steel; E5515-C2, C2, C3 – Increased Nickel content, Nickel Steel; E5518-NM – Nickel Molybdenum Steel; W6015-D1, D2, D3 – Increased Manganese content, Manganese Molybdenum Steel; E××10-G, E××03-G, etc.: Other low alloy steel welding rods.

| No | Grade | GB | AWS | JIS | DIN | |

| 1 | CHH507 | R507 | E5MoV-15 | E502-15 | DT2516 | EkbCrMo520+ |

| 2 | CHH707 | R707 | E9Mo-15 | E505-15 | EkbCrMo920+ | |

| 3 | CHH807 | R807 | E11MoVNi-15 | |||

| 4 | CHK202 | G202 | E410-16 | E410-16 | D410 | E13B20+ |

| 5 | CHK207 | G207 | E410-15 | E410-15 | E13B20+ | |

| 6 | CHK232 | E410NiMo-16 | E410NiMo-16 | |||

| 7 | CHK307 | G307 | E430-15 | E430-15 | D430 | E17B20+ |

| 8 | CHS002 | A002 | E308L-16 | E308L-16 | D308L | E199ncR23 |

| 9 | CHS002A | E308L-15 | E308L-15 | |||

| 10 | CHS012Si | A012Si | ||||

| 11 | CHS022 | A022 | E316L-16 | E316L-16 | D316L | E19123ncR26 |

| 12 | CHS022N | E316L-16 | E316L-16 | D316L | E19123ncR26 | |

| 13 | CHS022Si | A022Si | ||||

| 14 | CHS032 | A032 | E317MoCuL-16 | E317L-16 | ||

| 15 | CHS042 | A042 | E309MoL-16 | E309MoL-16 | ||

| 16 | CHS052 | A052 | ||||

| 17 | CHS052Cu | |||||

| 18 | CHS062 | A062 | E309L-16 | E309L-16 | ||

| 19 | CHS062A | E309L-15 | E309L-15 | |||

| 20 | CHS102 | A102 | E308-16 | E308-16 | D308-16 | E199R26 |

| 21 | CHS107 | A107 | E308-15 | E308-15 | E199B26 | |

| 22 | CHS122 | A122 | ||||

| 23 | CHS132 | A132 | E347-16 | E347-16 | D347-16 | E199NbR26 |

| 24 | CHS137 | A137 | E347-15 | E347-15 | D347-15 | E199NbB26 |

| 25 | CHS157Mn | |||||

| 26 | CHS202 | A202 | E316-16 | E316-16 | D316 | E19123R26 |

| 27 | CHS207 | A207 | E316-15 | E316-15 | E19123B20+ | |

| 28 | CHS212 | A212 | E318-16 | E318-16 | E19123NbR26 | |

| 29 | CHS222 | A222 | E317MoCu-16 | E316Cu-16 | ||

| 30 | CHS232 | A232 | E318V-16 | |||

| 31 | CHS237 | A237 | E318V-15 | |||

| 32 | CHS302 | A302 | E309-16 | E309-16 | D309-16 | E2312R26 |

| 33 | CHS307 | A307 | E309-15 | E309-15 | D309-15 | E2212B20+ |

| 34 | CHS312 | A312 | E309Mo-16 | E309Mo-16 | D309Mo-16 | E2312R26 |

| 35 | CHS402 | A402 | E310-16 | E310-16 | D310-16 | E2520R26 |

| 36 | CHS407 | A407 | E310-15 | E310-15 | D310-15 | E2520B26 |

| 37 | CHS412 | A412 | E310Mo-16 | E310Mo-16 | D310Mo-16 | |

| 38 | CHS437 | E310H-15 | B.S:25.20H | |||

| 39 | CHS502 | A502 | E16-25MoN-16 | E16-8-2-16 | D16-8-2 | |

| 40 | CHS507 | A507 | E16-25MoN-15 | E16-8-2-15 | D16-8-2 | |

| 41 | CHS29.9 | E312-16 | E312-16 | D312 | ||

| 42 | CHS29.9Co | |||||

| 43 | CHS2209 | E2209-16 | E2209-16 | |||

Comparison of old and new models of stainless steel welding rods and their application range:

| National Standards GB983-77 | National Standards GB983-85 | National Standards GB983-95 | Drying | Suitable for welding steel materials |

| A002 | E00-19-10-16 | E308L-16 | 150℃×1 h | 0Cr19Ni10; 0Cr19Ni11Ti; |

| A022 | E00-18-12Mo-16 | E316L-16 | 00Cr17Ni14 Mo2 | |

| A032 | E00-19-13Mo2-Cu2-16 | E317 Mo-CuL-16 | 0Cr18Ni12Mo2Cu2 | |

| A042 | E00-23-13Mo2-16 | E309 Mo L-16 | 00Cr23Ni13Mo2 | |

| A062 | E00-23-13-16 | E309 L-16 | 00Cr23Ni13 | |

| A101 | E0-19-10-16 | E308-16 | 1Cr19Ni9; Cr19Ni10; 0Cr19Ni11 | |

| A102 | E0-19-10-16 | E308-16 | 0Cr19Ni9; 0Cr19Ni11Ti | |

| A107 | E0-19-10-15 | E308-15 | 250℃×1 h | 0Cr19Ni9 |

| A132 | E0-19-10Nb-16 | E347-16 | 150℃×1 h | Cr19Ni11Ti |

| A137 | E0-19-10Nb-15 | E347-15 | 250℃×1 h | 0Cr19Ni11Ti |

| A201 | E0-18-12Mo2-16 | E316-16 | 250℃×1 h(Prohibit repeated baking.) | 0Cr18Ni12Mo2 |

| A202 | E0-18-12Mo2-16 | E316-16 | 150℃×1 h | 0Cr18Ni12Mo2 |

| A207 | E0-18-12Mo2-15 | E316-15 | 250℃×1 h | 0Cr18Ni12Mo2; Cr13; Cr17 |

| A242 | E0-19-13Mo3-16 | E317-16 | 150℃×1 h | Cr19Ni13Mo3 |

| A302 | E1-23-13-16 | E309-16 | Cr23Ni13 | |

| A307 | E1-23-13-15 | E309-15 | 250℃×1 h | Cr23Ni13 |

| A312 | E1-23-13Mo2-16 | E309 Mo -16 | 150℃×1 h | Cr23Ni13Mo2 |

| A402 | E2-26-21-16 | E310 -16 | Cr25Ni20 | |

| A407 | E2-26-21-15 | E310 -15 | 250℃×1 h | Cr25Ni20 |

| A412 | E1-21-21Mo2-16 | E310Mo -16 | 150℃×1 h | Cr26Ni21Mo2 |

| A422 | Cr25Ni20Si2 |

Description: 15, 25 – Alkaline, direct current reversed polarity; 16, 17, 26 – Titanium calcium type, alternating current or direct current reversed polarity.

| No | Grade | GB | AWS | JIS | |

| 1 | CHC100 | Z100 | |||

| 2 | CHC | Z | |||

| 3 | CHC208 | Z208 | EZC | ||

| 4 | CHC308 | Z308 | EZNi-1 | ENi-CI | DECNi |

| 5 | CHC408 | Z408 | EZNiFe-1 | ENiFe-CI | DFCNiFe |

| 6 | CHC508 | Z508 | EZNiCu-1 | ENiCu-B | DFCNiCu |

Comparison of old and new model numbers for low temperature steel welding rods and their application range

| National Standards GB982-77 | National Standards GB5118-95 | Drying | Suitable for welding steel materials. |

| W707 | 350℃×1 h | 09Mo2V; 09MnTiCuXi | |

| W707Ni | E5515-C1 | 09Mo2V; 16MnVAl; 3.5Ni Steel, etc. | |

| W907Ni | E5515-C2 | 3.5Ni steel should be preheated to 150℃, then tempered at a temperature range of 600-650℃. | |

| W107Ni | 06AlNbCuN;16MnNb; 3.5Ni steel |

| No | Grade | Welding Forms | GB | AWS | DIN | JIS |

| 1 | CHW-40CNH | Gas Shielded Welding | TB/T H08MnSiCuCrNi Ⅱ | |||

| 2 | CHW-50C | Gas Shielded Welding | ER49-1 | |||

| 3 | CHW-50C3 | Gas Shielded Welding | ER50-3 | ER70S-3 | YGW16 | |

| 4 | CHW-50C6 | Gas Shielded Welding | ER50-6 | ER70S-6 | SG2 | YGW12 |

| 5 | CHW-50C8 | Gas Shielded Welding | ER70S-G | |||

| 6 | CHW-60C | Gas Shielded Welding | ER80S-G | |||

| 7 | CHW-62B3 | Gas Shielded Welding | ER62-B3 | ER80S-B3 | ||

| 8 | CHW-S1 | Submerged Arc Welding | H08A (E) | EL12 | S1 | |

| 9 | CHW-S2 | Submerged Arc Welding | H08MnA | EM12 | S2 | |

| 10 | CHW-S3 | Submerged Arc Welding | H10Mn2 | EH14 | S4 | W41 |

| 11 | CHW-S4 | Submerged Arc Welding | H10MnSi | EM13K | ||

| 12 | CHW-S5 | Submerged Arc Welding | H08Mn2SiA | |||

| 13 | CHW-S6 | Submerged Arc Welding | ER50-6 | |||

| 14 | CHW-S7 | Submerged Arc Welding | H008Mn2MoA | |||

| 15 | CHW-S8 | Submerged Arc Welding | H13Cr2.25MolA | EB3 | ||

| 16 | CHW-S9 | Submerged Arc Welding | HO8MnMoA | EA2 | ||

| 17 | CHW-SG | Submerged Arc Welding | ||||

| 18 | CHW-SQ1 | Submerged Arc Welding | ||||

| 19 | CHW-SQ2 | Submerged Arc Welding | ||||

| 20 | CHW-G1 | Gas Welding | H08A | EL12 | 8557-S1 |

Welding Fluxes for Carbon Steel and Low Alloy Steel:

| No | Grade | GB | AWS | |

| 1 | CHF101 | SJ101 | F5A2-H10Mn2 | E7A0-EH14 |

| 2 | CHF101GX | |||

| 3 | CHF102 | F5A4-H10Mn2 | E7A4-EH14 | |

| 4 | CHF103 | SJ103 | F4A4-H108MnA | E6A4-EM12 |

| 5 | CHF105 | SJ105 | F5P5-H10Mn2 | E7P6-EH14 |

| 6 | CHF105GX | |||

| 7 | CHF105HR | F5131-H10Mn2 | E7P2-EH14 | |

| 8 | CHF106Fe | F5A2-H10Mn2 | E7A0-EH14 | |

| 9 | CHF113 | F7141-H08Mn2MoA | F62P4-EA4-A4 | |

| 10 | CHF115 | F8121-H08Mn2MoA | F69P2-EA4-A4 | |

| 11 | CHF201 | SJ201 | F5A4-H10Mn2 | E6A0-EM12 |

| 12 | CHF250 | HJ250 | ||

| 13 | CHF301 | SJ301 | F4A2-H08A | E6A0-EL12 |

| 14 | CHF302 | SJ302 | F5A2-H08A | E7A0-EL12 |

| 15 | CHF303 | SJ303 | F5A2-H10MnSi | F7A0-EM13K |

| 16 | CHF330 | HJ330 | F4A0-H10Mn2 | F6AZ-EH14 |

| 17 | CHF350 | HJ350 | F4A2-H10Mn2 | F6A0-EH14 |

| 18 | CHF360 | HJ360 | ||

| 19 | CHF431 | HJ431 | F4A2-H08A | F6A0-EL12 |

| 20 | CHF501 | SJ501 | F4A0-H08A | F6AZ-EL12 |

| 21 | CHF523 | F4A0-H08A | F6AZ-EL12 | |

| 22 | CHFGP60 | F4A0-H08A | F6AZ-EL12 | |

| 23 | CHF603 | |||

| 24 | CHF603HR |

Welding Fluxes for Stainless Steel, Non-ferrous Metals, and Repair Welding:

| No | Grade | GB | |

| 1 | CHF131 | HJ131 | |

| 2 | CHF150 | HJ150 | |

| 3 | CHF202 | SJ202 | |

| 4 | CHF203 | SJ203 | |

| 5 | CHF260 | HJ260 | F308-H0Cr21Ni10 |

| 6 | CHF304D | ||

| 7 | CHF521 | ||

| 8 | CHF522 | SJ522 | |

| 9 | CHF570 | SJ570 | |

| 10 | CHF601 | SJ601 | F308-H0Cr21Ni10 |

Understanding the characteristics of different welding rod grades is crucial for selecting the right rod for specific welding tasks. Each grade has distinct properties that make it suitable for particular applications, materials, and welding conditions.

By understanding the unique characteristics of these welding rod grades, welders can select the most appropriate rod for their specific needs, ensuring high-quality, reliable welds tailored to the demands of their projects.

In the realm of welding, selecting the appropriate welding rod grade is pivotal to achieving high-quality, durable welds. This section provides a detailed comparative analysis of some of the most commonly used welding rod grades, focusing on their unique characteristics, applications, and performance metrics.

Tensile Strength: 60,000 PSI

Welding Positions: All positions (flat, horizontal, vertical, and overhead)

Coating: High cellulose-sodium

Current: DC-only (DCEP)

Penetration: Deep

Arc Characteristics: Tight, erratic

Special Applications: E6010 is ideal for root passes, welding through dirty, oily, or painted surfaces, and stove pipe welding. It excels in pipeline welding due to its ability to penetrate surface contaminants and provide strong, reliable welds in all positions. For instance, E6010 is extensively used in the construction of oil and gas pipelines, where weld integrity is critical.

Tensile Strength: 60,000 PSI

Welding Positions: All positions

Coating: High cellulose-potassium

Current: AC and DC (DCEP & AC)

Penetration: Deep

Arc Characteristics: Tight, erratic

Special Applications: Similar to E6010, E6011 is versatile and preferred for general industrial tasks, including root passes and welding on dirty or painted surfaces. Its compatibility with both AC and DC power sources makes it a popular choice for home welding setups and for learners who need easier arc control. E6011 is often used in repair and maintenance work on farms, where equipment may have rust or other contaminants.

Tensile Strength: 60,000 PSI

Welding Positions: All positions

Coating: High titania-potassium

Current: AC, DCEN, and DCEP

Penetration: Shallow to medium

Arc Characteristics: Smooth

Special Applications: Known for its smooth arc and ease of use, E6013 is ideal for beginners and is commonly used for welding clean sheet metal. It produces a softer arc with moderate penetration, making it suitable for thin or light-gauge metals in light fabrication and automotive repair. E6013 is often chosen for projects such as car body repairs and thin metal structures due to its ease of use and clean weld appearance.

Tensile Strength: 70,000 PSI

Welding Positions: All positions except vertical down

Coating: Low-hydrogen iron

Current: AC and DC

Penetration: Medium

Arc Characteristics: Smooth, clear puddle

Special Applications: E7018 is a high-strength, low-hydrogen electrode used for structural welding, power generation, petrochemical applications, pressure vessels, and piping. Its low hydrogen content minimizes the risk of weld cracking, and it is highly resistant to hydrogen embrittlement, making it suitable for critical infrastructure projects. For example, E7018 is commonly used in the construction of bridges and high-rise buildings where weld strength and integrity are paramount.

When selecting the appropriate welding rod, consider the specific requirements of your project. Factors such as the type of metal being welded, the welding position, and the power source available are crucial. For instance, E6010 and E6011 are excellent for projects requiring deep penetration and the ability to weld through contaminants, while E6013 is ideal for clean, thin metals. E7018 is the go-to choice for high-strength, critical applications where weld integrity is essential. Understanding these differences can help ensure optimal performance and high-quality welds.

Selecting the appropriate welding rod grade is essential for achieving high-quality, durable welds. The choice of welding rod depends on various factors such as the type of metal being welded, the welding position, the power source available, and the specific requirements of the project. Understanding these factors will help you make an informed decision.

Different metals and their thicknesses require specific welding rod grades to ensure optimal performance. For example, mild steel, which is commonly used in construction, automotive, and general fabrication, requires particular attention to the choice of welding rod:

The welding position plays a crucial role in selecting the right rod. For instance, if you’re welding in various positions, you need a versatile rod:

Environmental factors such as the presence of contaminants, the power source, and whether the work is indoors or outdoors affect rod selection. For example:

Specific project requirements such as tensile strength, ease of use, and desired weld appearance also influence rod selection. For example:

Certain projects may have specific requirements that necessitate the use of specialized rods. For instance:

By carefully considering these factors and understanding the characteristics of different welding rod grades, you can select the most suitable rod for your project. This ensures high-quality welds that meet the specific demands of the task at hand.

Successfully using welding rods requires understanding the specific techniques and considerations for each grade. Here are detailed guidelines for effectively using some of the most common welding rod grades:

Preparation and Technique:

Applications:

Preparation and Technique:

Applications:

Preparation and Technique:

Applications:

Preparation and Technique:

Storage and Handling:

Applications:

Preparation and Technique:

Applications:

Purchasing high-quality welding rods is essential for achieving excellent weld results and ensuring the durability of your projects. Some of the most reputable brands known for their reliable and durable welding rods include:

When selecting welding rods, it is crucial to understand the different grades and their specific applications:

High-quality welding rods can be sourced from various retailers and online platforms, providing both convenience and a wide selection of products. Here are some of the best places to purchase welding rods:

To choose the right welding rods for your projects, consider the following factors:

By understanding the different welding rod grades, their specific applications, and where to purchase them, you can make informed decisions that lead to successful welding outcomes.

Below are answers to some frequently asked questions:

The numbers on welding rods are part of a classification system established by the American Welding Society (AWS) to indicate key characteristics of the electrode. These numbers provide information about the tensile strength, positional usability, and type of flux coating of the electrode.

Understanding these codes helps in selecting the right welding rod for specific projects, ensuring the appropriate tensile strength, positional usability, and flux characteristics are met.

Choosing the right welding rod for your project involves several key considerations to ensure a strong, durable, and high-quality weld. Start by identifying the composition and properties of the base metal you are welding. Matching the electrode composition to the base metal type is crucial. For example, when welding steel, select an electrode with a similar tensile strength to the base metal.

Next, consider the tensile strength of the electrode, which should match or exceed that of the base metal. This is indicated by the first two digits of the AWS (American Welding Society) classification on the electrode. For instance, an E6011 electrode has a minimum tensile strength of 60,000 psi.

The type of welding current (AC or DC) compatible with the electrode is also important. The fourth digit of the AWS classification reveals the type of coating and compatible welding current. For example, E6010 is suitable for DCEP (Direct Current Electrode Positive) for deep penetration, while E6013 is compatible with AC and produces a soft arc with medium penetration.

Additionally, consider the welding position. The third digit of the AWS classification indicates the qualified welding positions: 1 for all positions (flat, horizontal, vertical, and overhead) and 2 for flat and horizontal only. For example, a 7018 electrode can be used in all positions.

Evaluate the joint design and fit-up. For joints with tight fit-ups or those that are not beveled, electrodes like E6010 or E6011 that provide a digging arc are ideal. For joints with wide root openings, E6012 is suitable for bridging gaps.

The thickness of the base metal also dictates the size and type of electrode needed. Thicker materials require electrodes with maximum ductility and low hydrogen content to prevent weld cracking, while thinner materials benefit from smaller diameter electrodes with soft arcs, like E6013, to prevent burn-through.

Consider the environmental and service conditions the welded part will encounter. Use low hydrogen electrodes with higher ductility for high heat, low temperature, or repetitive shock loading to reduce the risk of weld cracking. Adhere to specific welding specifications for critical applications such as pressure vessel or boiler fabrication.

Finally, industry regulations and specific application requirements can dictate the use of certain electrodes. For example, in construction, welding must be robust for safety reasons, and specific electrodes may be mandated. By taking these factors into account and understanding the AWS classification system, you can select the right welding rod for your project.

The main difference between E6013 and E7018 welding rods lies in their tensile strength, coating, performance, ease of use, and typical applications.

E6013 welding rods have a tensile strength of 60,000 PSI and are coated with a titania potassium material. This provides a smooth penetrating arc and makes them versatile for use in all positions. E6013 rods are often recommended for beginners because they are easy to start and maintain the arc. They are ideal for lighter to medium penetration tasks, such as welding thin or sheet metal, and are commonly used in manufacturing truck frames, metal furniture, and farm implements. However, they tend to produce more spatter and have harder-to-remove slag.

On the other hand, E7018 welding rods have a higher tensile strength of 70,000 PSI and feature a low-hydrogen iron coating, which makes them crack-resistant and suitable for use in colder environments. E7018 rods produce minimal spatter, have easy slag release, and provide a smooth puddle flow. They require higher amperage and are better suited for high-strength applications, including structural welding and critical infrastructure projects like bridge construction. These rods need to be stored in a rod oven to prevent moisture absorption due to their low-hydrogen content. E7018 rods are known for their stable arc, ease of control, and ability to produce high-quality welds, making them a favorite among experienced welders.

In summary, E6013 rods are suitable for lighter applications and easier for beginners to use, while E7018 rods are preferred for demanding, high-strength applications and offer superior performance in challenging environments.

Using the same welding rod for different types of steel is generally not recommended due to the varying properties and compositions of different steels. The compatibility between the welding rod and the base metal is crucial to ensure a strong, durable, and reliable joint. For instance, welding low-carbon steel typically requires an electrode like E7018, which is suitable for low and medium-carbon steels. However, when welding dissimilar steels, such as alloyed steel to mild steel, specialized electrodes like ER312 stainless filler wire are necessary to accommodate the differences in material properties.

Additionally, the American Welding Society (AWS) classification system provides guidance on the appropriate electrode for specific steels, indicating tensile strength and suitable welding currents. For example, an E6011 electrode is designed for steels with a similar tensile strength.

Using the correct welding rod also depends on the welding technique and joint design. Some electrodes, like E6010 and E6011, are preferred for deep penetration and handling contaminants, while others, like E6013, are better for clean, new sheet metal.

Specialized electrodes are essential for specific applications, such as using E309 or E312 for welding stainless steel to mild steel, to prevent cracks and ensure weld integrity.

In summary, matching the electrode to the base metal composition, considering welding techniques and joint design, and using specialized electrodes for dissimilar metals are critical factors in selecting the appropriate welding rod. Therefore, using the same welding rod for different types of steel without these considerations is not advisable.

To purchase specialized welding rods, you have several reliable options. Online retailers such as WeldingMart offer a broad selection of high-quality stick electrodes from well-known brands like Lincoln Electric, including popular types like Excalibur 7018 MR and Fleetweld 5P+. Home improvement stores such as Lowe’s and Home Depot also stock a variety of welding rods from reputable brands, providing options in different sizes and classifications, such as AWS E6010 and AWS E6013. For those who prefer buying directly from manufacturers, Lincoln Electric’s official website and authorized distributors are excellent sources for high-quality products. Additionally, local suppliers like Air Liquide may carry welding rods, allowing for immediate access without waiting for shipping. When selecting specialized welding rods, consider your welding applications, required amperage, and the quality of the electrodes to ensure you choose the right products for your projects.