Ever wondered what tools and materials are essential for welding? This article covers everything you need to know about soldering irons, flux, soldering stands, and more. Whether you’re a beginner or a seasoned welder, you’ll learn about the different types of soldering irons, their uses, and the necessary precautions to take. Dive in to enhance your welding skills and ensure your projects are successful with the right tools at hand.

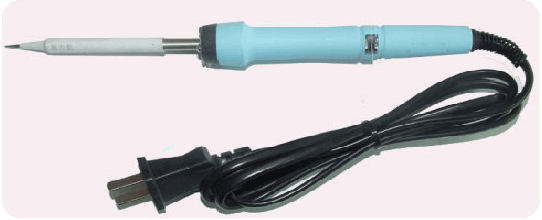

The soldering iron is a commonly used hand tool for welding, which heats the solder and the metal to be welded.

The molten solder wets the surface of the metal being welded and forms an alloy. The soldering iron is an indispensable tool in the assembly process of electronic products, and the commonly used types are as follows.

(1) External-heating Soldering Iron

The external-heating soldering iron consists of an iron tip, iron core, shell, wooden handle, power lead, and plug. Since the iron tip is installed inside the iron core, it is called an external-heating soldering iron.

Specifications

External heat soldering irons come in various specifications, including commonly used ones such as 25W, 45W, 75W, and 100W. The greater the power, the higher the temperature of the soldering tip.

Soldering Iron Core

The soldering iron core is a critical component of the soldering iron. It is constructed by winding the electric heating wire in parallel around a hollow ceramic tube, with mica insulating sheets in the middle, and two wires drawn out for connection to a 220V AC power source.

(2) Internal-heating Soldering Iron

The internal heating soldering iron is composed of a handle, connecting rod, spring clip, soldering iron core, and soldering iron tip. As the iron core is installed inside the tip, it heats up quickly and offers high thermal efficiency, hence it’s called an internal heating soldering iron.

Specifications

The common specifications for the internal heating soldering iron are 20W and 50W. Due to its high thermal efficiency, a 20W internal heating soldering iron is equivalent to an approximately 40W external heating soldering iron.

Features

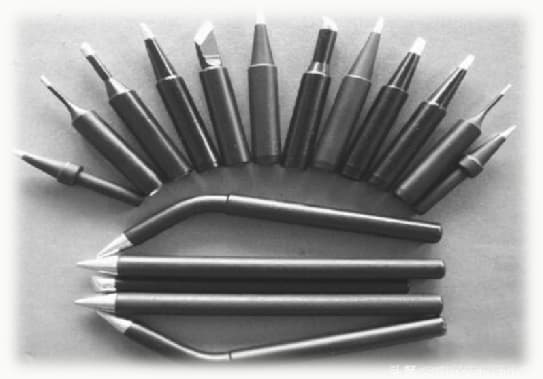

The rear end of the internal heating soldering iron is hollow, designed to fit over the connecting rod, and is secured with a spring clip. When it is necessary to replace the iron tip, the spring clip must first be removed. Then, using pliers, grip the front end of the iron tip and gently pull it out. It is crucial not to use excessive force to prevent damage to the connecting rod.

(3) Differences Between Internal Heating and External Heating Soldering Irons

1. Their structures differ, resulting in different heating methods.

2. Internal heating irons have less heat loss and a shorter preheating time; external heating irons experience larger heat loss, lower heating efficiency, and a slightly longer preheating time.

3. The shape of the soldering iron tips they use are distinct; the former is a hollow cylinder, while the latter is a solid rod.

4. Internal heating soldering iron tips have a shorter lifespan, and the iron core is prone to breakage; external heating soldering iron tips have a longer lifespan.

5. Internal heating irons have lower power, available in 20W, 35W, and 50W specifications, primarily used for soldering small components. External heating irons have higher power, with specifications ranging from 25W, 30W, 50W, to 75W, 100W, 150W, and 300W, suitable for soldering both small and large components.

Requirements:

When soldering integrated circuits and transistor components, the temperature cannot be too high, and the soldering time cannot be too long.

Otherwise, the components may be damaged due to excessive heat. Therefore, the temperature of the soldering iron must be regulated.

Principle:

The thermostatic soldering iron contains a magnetic temperature controller which controls the power-on time to achieve temperature control. When the soldering iron is powered on, its temperature rises.

Once it reaches the set temperature, the strong magnetic sensor reaches its Curie point, losing its magnetism, causing the magnetic core contact to break and thereby stopping the power supply to the soldering iron.

When the temperature falls below the Curie point of the strong magnetic sensor, the magnetism is restored, attracting the permanent magnet in the magnetic core switch, thereby making the control switch contact, and continuing to power the soldering iron. This cycle repeats, achieving the purpose of temperature control.

Advantages:

1. Intermittent heating not only saves power but also prevents the soldering iron from overheating, extending its lifespan.

2. Rapid heating time, only requiring 40 to 60 seconds.

3. The soldering iron tip utilizes a tinning quenching process, ensuring a longer lifespan.

4. The constant temperature is unaffected by power supply voltage and ambient temperature. For example, a 50W 270°C thermostatic soldering iron can maintain a constant temperature with a power supply voltage between 180V-240V, and can reach 270°C after being powered on for 5 minutes.

The temperature-controlled soldering iron comes equipped with a power controller, which allows for adjustments in the input power during use. The temperature can be regulated within a range of 100 to 400 degrees Celsius.

The maximum power for the temperature-controlled soldering iron is 60W, and it is paired with a copper-clad iron soldering tip, colloquially known as a long-life tip.

The solder sucker soldering iron is a desoldering tool that combines a piston-driven solder sucker with a soldering iron.

The operation of the solder sucker soldering iron is as follows: Plug in the power to preheat for 3 to 5 minutes, then push down and lock the piston handle; position the tip of the solder sucker soldering iron toward the solder joint to be desoldered, wait for the solder to melt, then press the button on the handle of the solder sucker soldering iron, the piston will automatically rise, and the solder gets sucked up by the tip, allowing the component lead to disconnect from the solder pad.

Additionally, the solder sucker comes with two or more different diameter tips, which can be selected based on the thickness of the component leads.

Features

The solder sucker soldering iron is noted for its ease of use, flexibility, and wide range of applications. One drawback of this type of solder sucker soldering iron is that it can only desolder one solder joint at a time.

The solder sucker soldering iron comes with its own power source, making it suitable for desoldering entire integrated circuits in situations where speed is not a high priority. The durability of the iron’s tip is determined by the materials used in the solder sucker nozzle, the heating tube, and the sealing ring.

(1) Long-Life Electric Soldering Iron

The long-life electric soldering iron shares the same structure and principle with the common type. The difference lies in the special process applied to the iron tip of the long-life model, which involves a coating of pure iron or nickel on the copper surface.

This treatment significantly extends its lifespan, typically making it about 20 times longer than that of a regular soldering iron. When using this type of soldering iron, tin should always be maintained on the iron tip.

(2) LongInfrared Soldering Torch

The heating principle of the infrared soldering torch involves infrared radiation. The infrared light source is placed on the reflective side of an ellipsoid, where the light rays converge at another focal point, reaching the temperature required for soldering.

This torch is suitable for soldering components like surface-mounted devices, particularly in the thermal forming and other heat welding operations of internally mounted tube pins and heat shrinkable plastics.

(3) LongEnergy-Storage Electric Soldering Iron

The energy-storage electric soldering iron is used for integrated circuits, especially for charge-sensitive MOS circuits. The soldering iron itself does not connect to a power source.

Upon being inserted into its matching power supply, the soldering iron enters an energy storage state. During soldering, the iron is removed, and the energy stored within is used to complete the soldering process, capable of soldering several joints at once.

(4) LongOthers

There are also other types of soldering irons, such as the carbon arc soldering iron powered by a rechargeable battery, the ultrasonic soldering iron that can remove the oxide layer from the soldered parts, and the automatic soldering iron equipped with an automatic soldering wire feeding device.

1. Select the appropriate type of soldering iron (power, shape) based on the object to be soldered.

2. It’s best to use a three-prong plug for the soldering iron. Ensure proper grounding of the casing.

3. Before use, thoroughly inspect the power plug and cord for damage. Check if the soldering iron tip is loose. Measure the resistance across the plug to ensure it meets requirements.

4. Avoid striking the soldering iron with force during use. Prevent it from falling. Excess solder on the iron tip can be wiped off with a cloth. Don’t fling it around to avoid burning others. Regular tinning should be performed during use.

5. The soldering iron should not be left haphazardly during use. When not soldering, place it on the soldering iron stand. Be careful not to let the power cord touch the soldering iron tip to prevent insulation layer damage and accidents.

6. After use, promptly disconnect the power and unplug the iron. Once cooled, store the soldering iron back in the toolbox.

The soldering iron stand is used for resting the soldering iron. The sponge located beneath the soldering iron stand is used for cleaning the soldering iron tip.

Caution:

1. Place the heated soldering iron on the soldering iron stand to prevent burns or fire hazards.

2. When using the water-absorbing sponge, ensure the water content is just enough to keep it upright without dripping. Excessive water can accelerate oxidation of the soldering iron tip at high temperatures, thereby reducing its lifespan.

A solder sucker is a tool used for desoldering.

Operating Steps:

1. First, push the piston rod of the solder sucker down until it locks.

2. Use a soldering iron to heat the solder joint until the solder melts.

3. While removing the soldering iron, quickly place the mouth of the solder sucker onto the solder joint and press the button of the sucker.

4. If the solder isn’t fully removed in one go, repeat the operation as needed.

Tweezers can be divided into pointed-tip tweezers and round-tip tweezers. The pointed-tip tweezers are used for holding thin wires, facilitating assembly and welding.

On the other hand, round-tip tweezers are utilized for gripping bent component leads and aiding in soldering processes. Using tweezers to hold components during soldering can also serve as a means of heat dissipation.

Diagonal pliers, also known as “side cutters”, can be used to cut the rubber or plastic insulation of soft electrical wires, as well as to cut wires and iron wires. They are commonly employed to trim the excess part of the extended leads of components after welding.

The screwdriver, also known as a turn-screw or driver, comes in two types: the flathead and the Phillips. It’s specifically used for turning screws, and the appropriate size should be chosen based on the size of the screw.

When adjusting inductive components like magnetic cores, a non-inductive screwdriver should be used.

Needle-nose pliers, also known as pointy-nose pliers, are primarily used for cutting thin wires, bending wire joints, and stripping plastic insulation. Its cutting edges can meticulously shear small components.

Welding materials refer to the general term for materials consumed during welding.

Advantages:

Utilizing solder as a welding flux features benefits such as a low melting point, excellent fluidity and adhesion, corrosion resistance, high mechanical strength, convenience of use, and low cost.

When a metal surface comes into contact with air, an oxide film is formed. The higher the temperature, the more severe the oxidation.

This oxide layer prevents molten solder from wetting the metal, like oil on glass preventing water from wetting it. Flux is a specific material used to remove this oxide film. Therefore, in tin-lead soldering, flux is an indispensable material.

Functions of Flux

During welding, only a small part is welded, and the rest is left un-welded to prevent damage to the remaining components. Therefore, it is essential to apply solder resist.

The solder resist serves the following purposes:

It helps avoid or reduce bridging and whiskering during welding, ensuring full solder joints, improving welding quality, guaranteeing product reliability, and reducing rework.

After using solder resist, soldering cannot be applied to all lines except for the solder pad, thereby saving a significant amount of soldering material. Moreover, due to less heat exposure and rapid cooling, the temperature of the printed circuit board can be reduced, which provides protection for the components and integrated circuits.

Residuals of the flux, which leaves traces after welding, need to be cleaned. The role of the cleaning agent is to remove flux, oil stains, and the like around the welding area.

The following are a few types of cleaning agents:

What damage can cleaning agents cause to the human body?