Have you ever wondered how welding transforms separate metal pieces into a unified whole? This article explores the fascinating world of weld joints, examining their types, mechanical characteristics, and the critical factors in their design. Discover how these joints impact the strength and durability of metal structures.

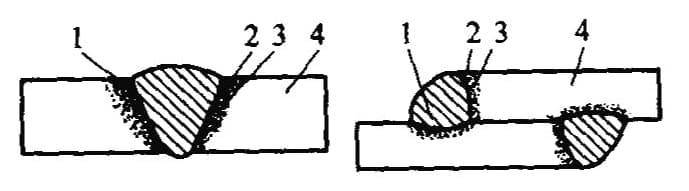

Arc welding joints are complex structures composed of four distinct regions, each with unique characteristics and properties:

1 – Weld Metal

2 – Melted Wire

3 – Heat-Affected Zone

4 – Base Material

Welding process imbues the joint with the following mechanical characteristics:

1) Heterogeneous Mechanical Performance of Welding Joints

Owing to various metallurgical processes taking place during welding, and due to the different thermal cycles and strain cycles affecting different areas, significant disparities in the structure and properties of these areas occur. This results in heterogeneous mechanical performance of the entire joint.

2) Uneven Stress Distribution and Concentration in Welding Joints

Geometric discontinuities inherent in welding joints lead to an uneven distribution of working stress and subsequent stress concentration. When welding defects are present, or when the shape of the welding seam or joint is impractical, the concentration of stress intensifies, affecting the joint strength, particularly its fatigue strength.

3) Residual Stress and Deformation Due to Uneven Heating During Welding

Welding is a localized heating process. During arc welding, the temperature at the weld seam can reach the material’s boiling point, but it rapidly decreases away from the seam down to room temperature. This uneven temperature field leads to residual stress and deformation within the weldment.

4) High Rigidity of Welding Joints

Through welding, the seam and the components become unified, yielding a higher degree of rigidity compared to riveted or shrunk joints.

Welded Joint (also referred to as a Joint): A joint connected by welding.

Commonly used welded joints:

Butt Joint, T-joint, Cross Joint, Lap Joint, Corner Joint, Edge Joint, Sleeve Joint, Bevel Butt Joint, Flanged Joint, and Double-V Butt Joint, among others.

The basic types of welded joints.

| Name | Weld seam formation | Name | Weld seam formation |

| Butt Joint |  | Terminal Connector |  |

| T-Joint |  | Oblique Butt Connector |  |

| Corner Joint |  | Flanged Connector | |

| Lap Joint |  | Sealed Butt Connector |

1. Butt Joint

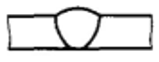

A butt joint is formed by welding together the abutting edges of two workpieces positioned in the same plane. This joint configuration is widely adopted in various welded structures due to its refined design, superior load-bearing capacity, high strength-to-weight ratio, and efficient utilization of materials.

The butt joint’s popularity stems from its ability to transmit forces directly through the weld, resulting in a more uniform stress distribution compared to other joint types. This characteristic makes it particularly suitable for applications involving cyclic loading or fatigue-prone environments, such as pressure vessels, pipelines, and structural steel frameworks.

However, the edge-to-edge nature of the connection imposes stringent requirements on the preparation and alignment of the mating surfaces. Precise edge preparation, including beveling for thicker materials, and maintaining tight fit-up tolerances are crucial for ensuring full penetration and minimizing the risk of weld defects.

In welding production, the weld bead of a butt joint typically exhibits a slight convex profile, protruding above the surface of the base material. While this reinforcement can provide additional strength, it also creates a geometric discontinuity. This non-uniform surface can lead to stress concentration at the weld toe – the transition zone between the weld metal and the base material. To mitigate this issue, post-weld treatments such as grinding or machining may be employed to achieve a flush surface, particularly in applications where fatigue resistance or aerodynamic properties are critical.

Modern welding techniques, such as automated laser welding or electron beam welding, can produce high-quality butt joints with minimal distortion and narrow heat-affected zones, further enhancing the joint’s mechanical properties and overall structural integrity.

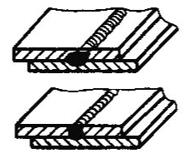

2. T-Joint

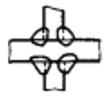

A T-joint (or cross joint) is formed by connecting perpendicular members using a fillet weld, creating a configuration resembling the letter “T”. This versatile joint can withstand multi-directional forces and torques, making it essential in various structural applications. T-joints are predominantly found in box structures, pressure vessel manufacturing (such as tube-to-shell connections), and the attachment of manhole reinforcement rings to vessel bodies.

The geometry of T-joints presents unique challenges in stress distribution. The abrupt transition from the weld seam to the base material causes significant distortion of the force flow under external loads, resulting in a highly non-uniform and complex stress field. This phenomenon leads to substantial stress concentrations at both the root and toe of the fillet weld, which are critical areas prone to fatigue failure.

To mitigate these stress concentrations and enhance joint performance, several strategies can be employed:

When designing and fabricating T-joints, engineers must carefully consider factors such as material selection, welding parameters, and potential loading scenarios to ensure optimal joint performance and longevity in service.

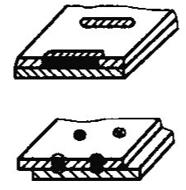

3. Lap Joint

A lap joint is created by overlapping two plates and then conducting a fillet weld on the end or side, or by adding a plug or groove weld. Due to the misalignment of the two plate centerlines in the lap joint, an additional bending moment is generated under load, which can affect weld strength.

Hence, lap joints are typically not utilized for the main pressure-bearing elements in boilers and pressure vessels.

The significant shape alteration in the components due to lap joints leads to a more complex stress concentration compared to butt joints, resulting in an extremely uneven stress distribution across the joint.

Within lap joints, based on the different directions of stress acting on the overlap fillet weld, these welds can be categorized as frontal, lateral, or diagonal fillet welds.

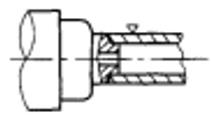

In addition to welding two steel plates stacked on the end or side, lap joints also involve groove welding and plug welding (round holes and elongated holes). The structure of a groove-welded lap joint is shown in the figure.

First, the workpiece to be connected is punched into a groove, and then the groove is filled with weld metal. The cross-section of the groove weld is rectangular, and its width is twice the thickness of the connected component. The length of the groove should be slightly shorter than the lap length.

Plug welding involves drilling holes in the plates to be joined, replacing the groove in groove welding, and using weld metal to fill these holes, thereby connecting the two plates. Plug welding can be divided into two types: circular hole plug welding and elongated hole plug welding, as shown in the figure.

4. Corner Joint

A corner joint is formed when two plates are welded at their edges at a certain angle. Corner joints are commonly used in box structures, saddle pipe joints, and connections with cylindrical bodies. The connection between fire tubes and end caps in small boilers also takes this form.

Similar to T-joints, single-sided corner joints have extremely low resistance to reverse bending moments. Unless the plates are very thin or the structure is not critical, bevels should generally be made for double-sided welding, otherwise, quality cannot be ensured.

When selecting the type of joint, consider primarily the structure of the product, as well as factors such as stress conditions and processing costs.

For instance:

Butt joints are widely used because they distribute stress evenly and save on metal. However, butt joints require precise cutting dimensions and assembly.

T-joints mostly endure minor shear stress or serve merely as connecting welds.

Lap joints do not demand high assembly precision and are easy to assemble, but their load-bearing capacity is low, so they are generally used in non-critical structures.

The requirements for weld quality, weld size, weld position, workpiece thickness, geometric dimensions, and working conditions in the design of welded joints determine the diversity in selecting welding methods and formulating processes. Reasonable design and selection of welded joints not only ensure the strength of the welds and the overall steel structure but also simplify the production process and reduce manufacturing costs.

Main factors in designing and selecting welded joints:

Table 1-2: Comparative Design of Weld Joint Forms

| Principles of Joint Design | Fault-prone design | Improved Design |

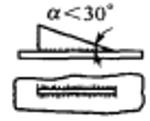

| Increase the front angle weld |  |  |

| The designed weld seam position should facilitate welding and inspection |  |  |

| To reduce stress concentration at the lap weld seam, it should be designed as a joint with certain stress relief |  |  |

| Cut off the sharp corners of the reinforcement ribs |  |  |

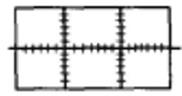

| Weld seams should be distributed |  |  |

| Avoid cross weld seams |  |  |

| Weld seams should be designed on or near the neutral axis in a symmetrical position |  |  |

| The weld seams subject to bending should be designed on the tension side, not on the unwelded compression side. |  |  |

| Avoid placing weld seams where stress is concentrated. |  |  |

| Weld seams should steer clear of areas with maximum stress. |  |  |

| The processing surface should be free of welding seams. |  |  |

| The position of the automatic welding seams should be designed where the adjustment of welding equipment and the number of workpiece flips are minimized. |  |  |

A weld seam is the joint formed after welding parts together.

Categories:

1. Based on spatial positioning, it can be divided into: flat weld seams, horizontal weld seams, vertical weld seams, and overhead weld seams.

2. Based on the method of jointing, it can be categorized into: butt weld seams, corner weld seams, and plug weld seams.

3. Based on continuity, it can be classified as: continuous weld seams and intermittent weld seams.

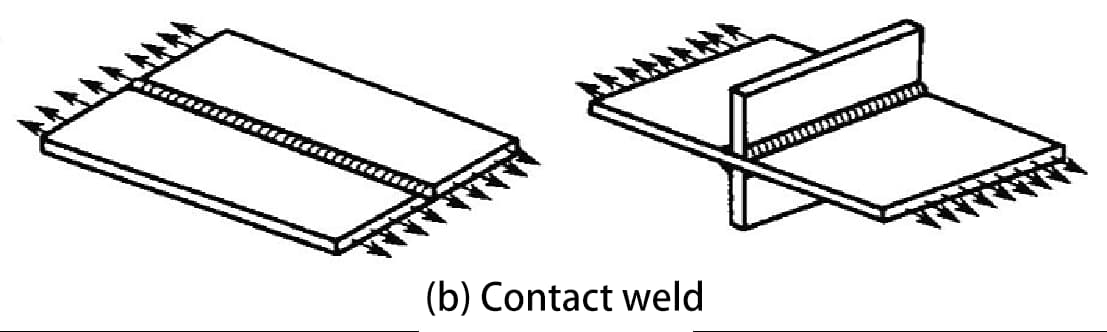

4. Based on load-bearing, it can be split into: working weld seams and contact weld seams.

The weld seam is a crucial component of the welded joint. The basic forms of the weld seam are the butt joint weld seam and the corner joint weld seam.

1. Butt Weld Seams:

Butt weld seams are formed along the junction between two parts. They can either have an un-grooved (or I-shaped groove) or a grooved configuration. The surface shape of the weld seam can either be convex or flush with the surface.

2. Corner Weld Seams:

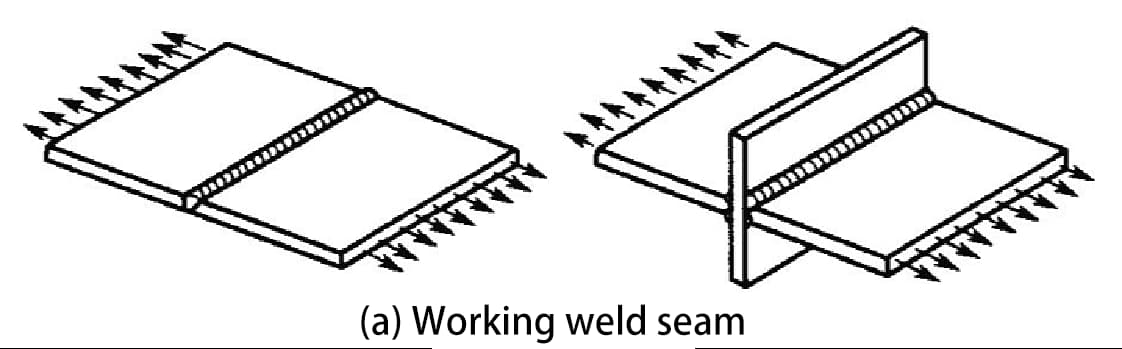

Working Weld Seams (also known as Load-Bearing Weld Seams)

These are weld seams that, in series with the welded parts, primarily bear loads. Should these seams rupture, the steel structure would immediately suffer severe damage.

Contact Weld Seams (also known as Non-Load-Bearing Weld Seams)

These are weld seams that parallelly unify two or more welded parts (i.e., providing connectivity). These seams do not directly bear loads and are subject to minimal force during operation. If such a seam were to rupture, the structure would not fail immediately.

A groove is a trench formed by machining certain geometric shapes at the to-be-welded parts of a workpiece according to design or process requirements.

Groove preparation:

The process of machining the groove using mechanical methods, flame, or electric arc.

Purpose of groove preparation:

(1) To ensure the arc penetrates deep into the root of the weld seam for complete fusion, to achieve an optimal weld seam formation, and to facilitate slag removal.

(2) For alloy steels, the groove also adjusts the ratio of base metal to filler metal (i.e., fusion ratio).

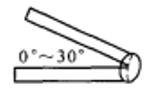

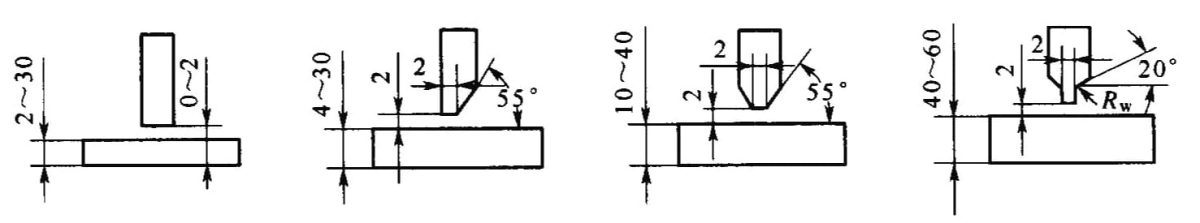

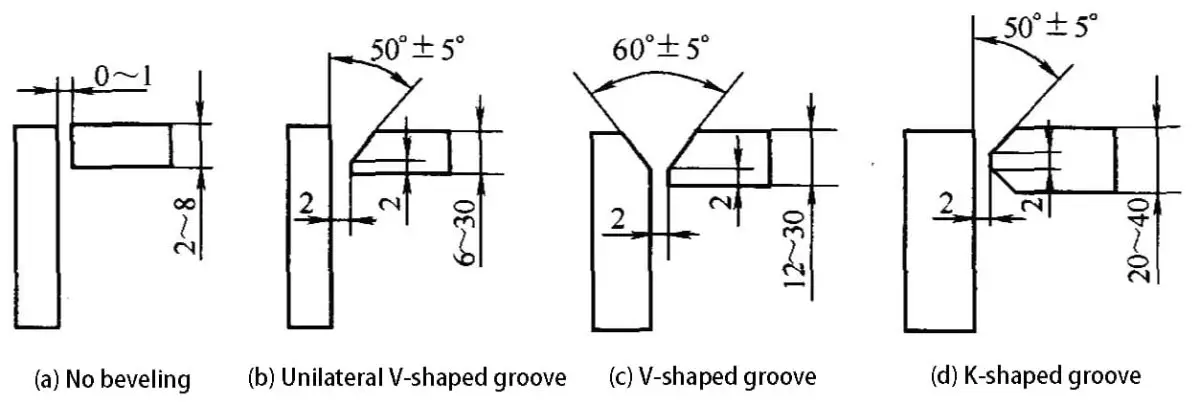

Depending on the thickness of the plate, the welding edges of butt weld seams can be rolled, squared, or machined into V-shape, X-shape, K-shape, and U-shape grooves.

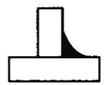

(2) Depending on the thickness of the workpiece, the structure, and load-bearing conditions, the groove shapes for corner joints and T-joints can be divided into I-shape, single-sided V-shape with a blunt edge, and K-shape.

a) I-shape

b) Single-Sided V-shape (with blunt edge)

c) K-shape (with blunt edge)

2. Principles for Groove Design

The form and dimensions of the groove are primarily chosen and designed based on the thickness of the steel structure, the selected welding method, the welding position, and the welding process. The design should:

1) Minimize the amount of filler material in the weld seam;

2) Exhibit good weldability;

3) Ensure the groove shape is easy to machine;

4) Facilitate adjustment of welding deformation;

In general, for welding workpieces up to 6mm thick using electrode arc welding, or for automatic welding of workpieces up to 14mm thick, it is possible to obtain a qualified weld seam without groove preparation.

However, a gap must be maintained between the plates to ensure the filler metal fills the weld pool, ensuring complete fusion. If the steel plate exceeds the above-mentioned thickness, the arc cannot penetrate through the plate, and groove preparation should be considered.

To ensure precise and accurate fabrication of their designs, engineers must comprehensively communicate the technical specifications of structures and products through detailed design drawings and comprehensive specification documents.

For welded joints, designers primarily utilize standardized weld symbols and welding process codes. While traditional technical drafting methods can be employed, graphically or textually detailing the intricate welding process requirements and considerations for complex joints can become excessively cumbersome and prone to misinterpretation.

Consequently, the implementation of standardized symbols and codes is crucial for unambiguously specifying the following critical aspects of welded joints:

These standardized representations not only streamline the design-to-fabrication workflow but also minimize communication errors, enhance productivity, and ensure consistent quality across various manufacturing environments. Furthermore, they facilitate easier compliance with international welding standards such as AWS A2.4 or ISO 2553, which are essential for global manufacturing operations and quality assurance.

Weld seam symbols: Symbols marked on the drawings to represent the form, size, and method of the weld seam.

They are regulated by GB/T324-1998 “Symbolic Representation of Weld Seams” (applicable to metal fusion welding and resistance welding) and GB/T5185-1999 “Representation Codes for Metal Welding and Brazing Methods on Drawings.

A weld seam symbol consists of:

Basic symbols: These symbols represent the cross-sectional shape of the weld seam, approximating the shape of the weld seam’s cross-section.

| Weld Seam Names | Cross-sectional shape of the weld seam. | Symbol |

| I-shaped Weld Seam |  |  |

| V-shaped Weld Seam |  |  |

| Blunt-edged V-shaped Weld Seam |  |  |

| Single-sided V-shaped Weld Seam |  |  |

| Blunt-edged Single-sided V-shaped Weld Seam |  | |

| Blunt-edged U-shaped Weld Seam |  |  |

| Sealing Weld Seam |  | |

| Fillet Weld |  |  |

| Plug Weld or Groove Weld |  |  |

| Flare-V Weld |  |  |

| Spot Weld |  |  |

| Seam Weld |  |  |

Supplementary Symbols: These symbols represent additional requirements for the surface shape characteristics of the weld seam. Supplementary symbols are generally used in conjunction with basic weld seam symbols when there are special requirements for the surface shape of the weld seam.

| Name | Assisted Welding Technique | Symbol | Instructions |

| Flat Symbol |  | Indicates a flush weld surface. | |

| Concave Symbol |  | Indicates a concave weld surface. | |

| Convex Symbol |  | Indicates a convex weld surface. |

Weld reinforcement symbols: These are symbols used to further illustrate certain characteristics of a weld seam.

| Name | Form | Symbol | Indication |

| Symbol with Pad |  | Indicates the presence of a backing strip at the bottom of the weld seam. | |

| Three-Sided Weld Symbol |  |  | Suggests three-side weld seams and the direction of the opening. |

| Perimeter Weld Symbol |  |  | Symbolizes a weld seam surrounding the workpiece. |

| Field Symbol |  | Denotes welding performed on-site or at a construction site. | |

| Tail Symbol |  | Reference to the tail end of the lead line symbol can be made to GB5185-1999 for welding methods and similar notations.” |

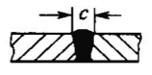

Weld seam dimension symbols: These are symbols used to represent the dimensions of groove and weld seam features.

| Symbol | Name | Schematic Diagram |

| σ | Sheet thickness |  |

| c | Weld seam width |  |

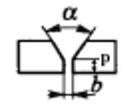

| b | Root gap |  |

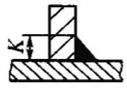

| K | Weld toe height |  |

| p | Blunt edge height |  |

| d | Weld spot diameter |  |

| a | Groove angle |  |

| h | Weld Reinforcement |  |

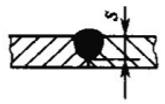

| s | Effective Weld ThicknessSame Weld Joint |  |

| N | Quantity Symbol |  |

| e | Weld Spacing |  |

| l | Weld Length |  |

| R | Root Radius |  |

| H | Groove height |  |

Leader Line: Composed of an arrowed leader line, two reference lines (horizontal lines) – one solid line and another dashed line, and a tail section.

In order to simplify the annotation and textual explanation of welding methods, the codes representing various welding methods such as metal welding and brazing, as denoted by Arabic numerals according to the national standard GB/T 5185-1999, can be utilized.

The welding method annotations are located at the end of the guide line.

| Name | Welding method |

| Arc Welding | 1 |

| Shielded Metal Arc Welding | 111 |

| Submerged Arc Welding | 12 |

| Metal Inert Gas Welding (MIG) | 131 |

| Tungsten Inert Gas Welding (TIG) | 141 |

| Pressure Welding | 4 |

| Ultrasonic Welding | 41 |

| Friction Welding | 42 |

| Diffusion Welding | 45 |

| Explosion Welding | 441 |

| Resistance Welding | 2 |

| Spot Welding | 21 |

| Seam Welding | 22 |

| Flash Welding | 24 |

| Gas Welding | 3 |

| Oxy-Acetylene Welding | 311 |

| Oxy-Propane Welding | 312 |

| Other Welding Methods | 7 |

| Laser Welding | 751 |

| Electron Beam | 76 |

Schematic Representation of Welds

According to the national standard GB/Tl2212-1990 “Technical Drawing – Dimensions, Proportions, and Simplified Representation of Welding Symbols“, when it is necessary to depict welds in a simplified manner on drawings, they can be represented using views, sectional views, or cross-sectional views, or even axonometric views for illustrative purposes.

Generally, only one type of representation is permitted per drawing.

(a) Drawing method of weld end face view

(b) Drawing method of weld seam section view

(c) Drawing method of weld profile

The National Standard GB/T324-1988, GB/T5185-1999, and GB/T12212-1990 each stipulate the annotation methods for weld symbols and welding method codes.

(1) Weld symbols and welding method codes can be accurately and unambiguously represented through guide lines and relevant regulations.

(2) When annotating welds, first annotate the basic weld symbols on top or below the reference lines, and other symbols are annotated in their respective positions as prescribed.

(3) There are generally no specific requirements for the position of the arrow line relative to the weld, but when annotating V-shaped, single-side V-shaped, J-shaped, etc., welds, the arrow should point to the workpiece with the groove.

(4) When necessary, the arrow line can be bent once.

(5) The imaginary reference line can be drawn above or below the real reference line.

(6) The reference line should generally be parallel to the bottom edge of the drawing, but under special conditions, it can also be perpendicular to the bottom edge.

(7) If the weld and the arrow line are on the same side of the joint, the basic weld symbol is annotated on the side of the actual reference line; conversely, if the weld and the arrow line are not on the same side of the joint, the basic weld symbol is annotated on the side of the imaginary reference line.

When necessary, the basic weld symbol can be accompanied by size symbols and data.

Annotation Principles:

1) The dimensions on the cross-section of the weld seam are marked on the left side of the basic symbol, such as: blunt edge height p, groove height H, weld angle size K, weld seam residual height h, effective thickness of the weld seam S, root radius R, weld seam width C, and weld nugget diameter d.

2) The dimensions in the direction of the weld seam length are marked on the right side of the basic symbol, such as: weld seam length L, weld seam gap e, and number of identical weld seams n.

3) The groove angle α, groove face angle β, root gap b, and other dimensions are marked on the upper or lower side of the basic symbol.

4) The symbol for the number of identical weld seams is marked at the tail end.

5) When there are many dimensions to be marked and they are not easy to distinguish, the corresponding dimension symbol can be added in front of the data.

| Name | Schematic Diagram | Labeling |

| Butt Weld Seam |  |  |

|  | |

| Intermittent Fillet Weld Seam |  |  |

| Staggered Intermittent Fillet Weld Seam |  |  |

| Spot Weld Seam |  |  |

| Seam Weld Seam |  |  |

| Plug Weld Seam or Groove Weld Seam |  |  |

In GB/T12212-1990, simplified annotation methods for welding joints are also stipulated under certain circumstances.