Imagine a world without welding. From towering skyscrapers to intricate machinery, the very fabric of our modern society would unravel. In this article, we explore the fascinating realm of welding methods and processes that shape our world behind the scenes. Discover the science, artistry, and innovation that breathe life into metal, and gain a newfound appreciation for the unsung craftsmen who make it all possible.

In this article, we will introduce 8 different types of welding methods and processes in detail, including definitions, working principles, features, advantages, etc.

I believe you will have a new understanding of the welding methods after reading this.

Let’s dive right into it.

Welding rod electric arc welding is a process method that uses the stable burning arc established between the welding rod and the workpiece to melt the welding rod and the workpiece, so as to obtain a firm welding joint.

During welding, the coating is continuously decomposed and melted to generate gas and slag, which protects the electrode end, arc, molten pool and its surrounding areas, and prevents harmful pollution of the atmosphere to the molten metal.

The welding core also melts continuously under the action of arc heat and enters the molten pool to form the filler metal of the weld.

1. Compared with other arc welding methods, electrode arc welding has the following advantages:

1. Simple equipment, flexible and convenient operation, strong adaptability, good accessibility, free from the restriction of site and welding position, and welding can be generally carried out where the electrode can reach.

These are important reasons for the wide application of shielded metal arc welding.

2. There are a wide range of weldable metal materials.

Almost all metals can be welded except those that are insoluble or easily oxidized.

3. The requirements for the assembly quality of the joint are low. During the welding process, the arc is controlled manually by the welder.

The welding process parameters can be modified by timely adjusting the arc position and electrode speed, reducing the quality requirements for the joint assembly.

2. Compared with other arc welding methods, electrode arc welding has the following disadvantages:

1. The welding productivity is low and the labor intensity is high.

Compared with other arc welding methods, the welding current is low, and the welding rod must be replaced after each welding rod is completed.

Slag cleaning is also required after welding.

The production efficiency is low and the labor intensity is high;

And the arc light is strong and the smoke is heavy.

2. The weld quality is highly dependent on people.

Since manual welding electrodes are used for welding, there are requirements for the welder’s operating skills, working attitude and field play.

The welding quality depends largely on the welder’s operating level.

Welding rod electric arc welding is composed of welding power source, welding cable, welding tongs, welding rods, weldments and electric arcs.

During welding, the welding rods and workpieces are used to contact and ignite the electric arcs, and then the welding rods are lifted and kept at a certain distance.

Under the condition that the welding power supply provides appropriate arc voltage and welding current, the electric arcs burn steadily to produce high temperatures, and the welding rods and weldments are locally heated to the melting state.

The molten metal at the end of the electrode is fused with the molten weldment metal to form a molten pool.

In welding, the arc moves with the electrode, and the liquid metal in the molten pool gradually cools and crystallizes to form a weld, and the two weldments are welded together.

In welding, the welding core of the electrode is transferred to the molten pool in the form of molten droplets after melting, and the electrode coating generates a certain amount of gas and liquid slag.

The gas generated is filled around the arc and molten pool to isolate the air.

The density of the liquid slag is smaller than that of the liquid metal, and it floats on the molten pool to protect the molten pool.

When the metal in the molten pool cools and solidifies, the slag also solidifies to form a welding slag covering the weld surface, preventing the high-temperature weld metal from being oxidized, and reducing the cooling rate of the weld.

In the welding process, complex metallurgical reactions such as deoxidation, desulfurization, dephosphorization and dehydrogenation are carried out between the liquid metal and the liquid slag and gas, so that the weld metal can obtain appropriate chemical composition and structure.

TIG welding is also known as non consumable inert gas arc welding.

Whether manual welding or automatic welding of 0.5~4.0mm thick stainless steel, TIG welding is the most commonly used welding method.

The method of TIG welding with filler wire is often used for backing welding of pressure vessels, because TIG welding has good gas tightness, which can reduce the porosity of welds during welding of pressure vessels.

The heat source of TIG welding is DC arc, the working voltage is 10~95 V, but the current can reach 600 A.

The correct connection mode of the welding machine is that the workpiece is connected to the positive pole of the power supply, and the tungsten electrode in the welding torch is used as the negative pole.

The inert gas is generally argon.

Inert gas is fed through the welding torch to form a shield around the arc and on the welding pool.

To increase heat input, 5% hydrogen is generally added to argon.

However, when welding ferritic stainless steel, hydrogen cannot be added in argon. The gas consumption is about 3-8 liters per minute.

In addition to blowing inert gas from the welding torch, it is better to also blow the gas used to protect the back of the weld from under the weld.

If necessary, the weld pool can be filled with welding wire with the same composition as the austenitic material to be welded.

When welding ferritic stainless steel, type 316 filler is usually used.

Gas shielded arc welding is a kind of arc welding method using external gas as the protective medium.

Its advantages are good visibility of arc and molten pool and easy operation;

There is no slag or little slag, so there is no need to clean slag after welding.

However, special windproof measures shall be taken when working outdoors.

According to whether the electrode is melted during welding, gas shielded welding can be divided into non melting electrode (tungsten electrode) gas shielded welding and consumable electrode gas shielded welding.

The former includes tungsten inert gas welding, plasma arc welding and atomic hydrogen welding.

Atomic hydrogen welding is rarely used in production at present.

Tungsten Inert Gas Welding (TIG) welding is a welding method using the arc generated between the tungsten electrode and the workpiece to heat melt the base metal and filler wire (if filler wire is used) under the protection of inert gas.

During welding, the shielding gas is continuously sprayed from the nozzle of the welding gun, forming a gas protective layer around the arc to isolate the air, so as to prevent its harmful effects on the tungsten electrode, the weld pool and the adjacent heat affected zone, so as to obtain high-quality welds.

Argon, helium or argon helium mixture can be used as shielding gas.

In special applications, small amounts of hydrogen can be added.

Argon is used as the shielding gas for tungsten argon arc welding and helium is used for tungsten helium arc welding.

Due to the high price of helium, tungsten argon arc welding is much more widely used in industry than helium arc welding.

TIG welding can be divided into manual welding, semi-automatic welding and automatic welding according to the operation mode.

During manual argon tungsten arc welding, the movement of the welding gun and the addition of filler wire are completely manual;

During semi-automatic argon tungsten arc welding, the welding gun movement is manually operated, but the filler wire is automatically fed by the wire feeding mechanism;

During automatic argon tungsten arc welding, if the workpiece is fixed and the arc moves, the welding gun is installed on the welding trolley, and the trolley travel and filler wire can be added in the way of cold wire or hot wire.

Hot wire refers to increasing the deposition speed.

In some cases, such as sheet welding or backing pass, it is sometimes unnecessary to add filler wire.

Among the above three welding methods, manual argon tungsten arc welding is the most widely used, while semi-automatic argon tungsten arc welding is rarely used.

During TIG welding, due to the low current density and the low thermal conductivity of argon, the arc is basically not compressed, and the static characteristics of the arc are horizontal.

According to the requirements of the static characteristics of the arc on the external characteristics of the power supply, the power supply with reduced external characteristics should be used regardless of whether the AC power supply or the DC power supply is used.

During TIG welding, small changes in arc length will cause great fluctuations in the welding power source.

Therefore, the ideal TIG welding power source is a power source with vertical steep drop external characteristics (such as magnetic amplifier type silicon arc welding rectifier), which can eliminate current fluctuations caused by changes in arc length.

AC power supply is generally used for TIG welding of aluminum, magnesium and their alloys.

MIG welding (MIG welding) is an electric arc welding method that uses the melting electrode, external gas as the arc medium, and protects metal droplets, welding pool and high temperature metal in the welding area. It is called MIG welding.

Inert gas (Ar or He) arc welding with solid wire is called MIG welding.

Related reading: MIG vs TIG Welding

Unlike TIG welding, MIG (MAG) welding uses a fusible welding wire as the electrode, and uses the burning arc between the continuously fed welding wire and the workpiece to be welded as the heat source to melt the welding wire and the base metal.

During the welding process, the shielding gas argon is continuously transmitted to the welding area through the welding gun nozzle, so that the arc, the molten pool and the base metal nearby are free from the harmful effects of the surrounding air.

The continuous melting of the welding wire shall be transferred to the welding pool in the form of droplets, and the weld metal shall be formed after fusion and condensation with the molten base metal.

1. Like TIG welding, it can weld almost all metals, especially suitable for welding aluminum and aluminum alloys, copper and copper alloys, stainless steel and other materials.

In the welding process, there is almost no oxidation burning loss, only a small amount of evaporation loss, and the metallurgical process is relatively simple.

2. High labor productivity.

3. MIG welding can be DC reverse connection. Welding aluminum, magnesium and other metals has a good cathodic atomization effect, which can effectively remove the oxide film and improve the welding quality of the joint.

4. Tungsten electrode is not used, and the cost is lower than TIG welding; It is possible to replace TIG welding.

5. When MIG welding aluminum and aluminum alloy, sub jet droplet transfer can be used to improve the quality of welded joints.

6. As argon is an inert gas and does not react with any substance, it is sensitive to the oil stain and rust on the surface of welding wire and base metal, and easy to generate air holes.

Before welding, the welding wire and workpiece must be carefully cleaned.

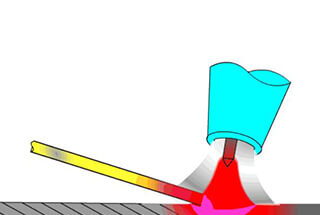

Laser welding is a method of welding by using focused laser beam as energy to bombard the heat generated by the weldment.

Because of the optical properties of laser, such as refraction and focusing, laser welding is very suitable for welding micro parts and parts with poor accessibility.

Laser welding also has the characteristics of low heat input, small welding deformation and immunity from electromagnetic field.

At present, laser welding has not been widely used because of the high price of laser and low electro-optic conversion efficiency.

Related reading: Laser Welding: The Basic Guide

1. Laser welding can be divided into manual laser welding machine, automatic laser welding machine and galvanometer laser welding machine according to the control mode

2. According to the laser source, it can be divided into: YAG laser welding machine, semiconductor laser welding machine, and fiber laser welding.

There are two basic modes of laser welding: laser thermal conduction welding and laser deep penetration welding.

The former uses a low laser power density (105~106W/cm2).

After the workpiece absorbs the laser, it only reaches the surface melting, and then relies on heat transfer to guide the internal heat transfer of the workpiece to form a molten pool.

This welding mode has shallow penetration and small depth width ratio.

The latter has a high laser power density (106~107W/cm2).

After absorbing the laser, the workpiece quickly melts and even vaporizes.

The molten metal forms a small hole laser beam under the action of steam pressure, which can directly shine on the hole bottom, making the hole continuously extend until the vapor pressure in the hole is balanced with the surface tension and gravity of the liquid metal.

When the keyhole moves along the welding direction with the laser beam, the molten metal in front of the keyhole flows around the keyhole to the rear, and the weld is formed after solidification.

This welding mode has a large penetration and a large depth to width ratio.

In the field of mechanical manufacturing, except for those thin parts, deep penetration welding should generally be used.

Metal vapor and shielding gas generated during deep penetration welding are ionized under the action of laser, thus forming plasma inside and above the keyhole.

Plasma can absorb, refract and scatter laser, so generally, the plasma above the molten pool will weaken the laser energy reaching the workpiece.

It also affects the focusing effect of the beam and is unfavorable for welding.

It is usually possible to expel or weaken the plasma by side blowing.

The formation of keyhole and plasma effect make the welding process accompanied by characteristic sound, light and electric charge.

It is of great theoretical significance and practical value to study the relationship between them and welding specifications and weld quality, and to monitor the laser welding process and quality using these characteristic signals.

1. The heat input can be reduced to the minimum required amount, the metallographic change range of the heat affected zone is small, and the deformation caused by heat conduction is also the minimum.

The welding process parameters of single pass welding of 2.32mm thick plate are qualified after verification, which can reduce the time required for thick plate welding and even save the use of filler metal.

3. There is no need to use electrodes, and there is no concern about electrode pollution or damage.

And because it is not a contact welding process, the wear and deformation of the machine can be minimized.

4. The laser beam is easy to focus, align and be guided by optical instruments, can be placed at a proper distance from the workpiece, and can be guided again between the machines and tools or obstacles around the workpiece.

Other welding rules cannot be used because of the above space restrictions.

5. The workpiece can be placed in a closed space (under the control of vacuum pumping or internal gas environment).

6. The laser beam can be focused on a very small area and can be used to weld small parts with similar spacing.

7. The range of weldable materials is wide, and various heterogeneous materials can also be joined together.

8. It is easy to carry out high-speed welding automatically, and can also be controlled by digital or computer.

9. When welding thin materials or thin diameter wires, there will be no reflow problem like arc welding.

10. It is not affected by magnetic field (arc welding and electron beam welding are easy), and can accurately align the weldment.

11. It can weld two metals with different physical properties (such as different resistance).

12. No vacuum or X-ray protection is required.

13. If piercing welding is adopted, the depth width ratio of weld bead can reach 10:1.

14. The device can be switched to transmit the laser beam to multiple workstations.

Electrons are one of the basic particles of matter, which usually revolve around the nucleus at high speed.

When electrons are given a certain amount of energy, they can jump out of orbit.

Heat a cathode to release and form a free electron cloud.

When the voltage is increased to 30 to 200 kv, the electrons will be accelerated and move towards the anode.

The basic principle of electron beam welding is that the cathode in the electron gun emits electrons due to direct or indirect heating.

With the acceleration of the high-voltage electrostatic field, the electrons can form an electron beam with high energy density through the focusing of the electromagnetic field.

With this electron beam to bombard the workpiece, the huge kinetic energy is converted into heat energy, so that the workpiece at the welding point is melted, forming a molten pool, thus realizing the welding of the workpiece.

Electron beam welding is widely used in aerospace, atomic energy, national defense and military industry, automobile and electrical instrument industries due to its advantages of no welding rod, no oxidation, good process repeatability and small thermal deformation.

In heavy industry, the power of electron beam welding machine has reached 100 kilowatts, and it can weld stainless steel plates with a thickness of 200 mm.

When welding large workpieces, large volume vacuum chamber shall be used, or movable local vacuum shall be formed at the welding position.

In automobile production, electron beam welding is mostly used to process parts of engines, transmissions, etc.

These parts are relatively less machined, which meets the economic requirements of electron beam welding.

As a modern advanced welding technology, electron beam welding also plays an important role in the aerospace field.

The uniqueness of materials and welding requirements for aerospace components, ranging from micro pressure sensors to spacecraft shells, make electron beam welding rapidly become a necessary process for processing these important components, which is widely used in the welding of important aircraft bearing parts and engine rotor components.

High voltage power supply for electron beam welding machine has different technical characteristics compared with other types of high voltage power supply.

According to the factory standards of foreign manufacturers of electron beam welding machines, German DIN standards and the technical requirements of China’s electron beam welding machines, the requirements of high-voltage power supply for electron beam welding machines are as follows:

Since there is no uniform standard at home and abroad for the technical requirements of high-voltage power supply for electron beam welding machines, the technical requirements proposed by some manufacturers are mainly ripple coefficient and stability.

The ripple coefficient is required to be less than 1%, and the stability is ± 1%.

Almost all manufacturers of electron beam welding machines have put forward such requirements.

PTR of Germany also put forward the technical requirements for medium voltage type, which requires the relative ripple coefficient to be less than 0.5%, the stability to be ± 0.5%, and the repeatability to be less than 0.5%.

The above requirements are determined according to the electron beam spot and welding process.

In addition, German Pro-beam Group proposed that the carbon content of the steel made by electron beam hardening must be greater than 0.18%.

The advantage of vacuum is that there is no color change and hydrogen embrittlement after annealing, the depth is between 0.1-1.7 mm, and there is no surface dissolution.

Plasma arc welding is a fusion welding method using plasma arc high energy density beam as welding heat source.

Plasma arc welding is characterized by energy concentration, high productivity, fast welding speed, small stress deformation, stable arc and suitable for welding thin plates and boxes.

It is especially suitable for welding various refractory, easily oxidized and heat sensitive metal materials (such as tungsten, molybdenum, copper, nickel, titanium, etc.).

The gas dissociates when heated by the arc, and is compressed when passing through the water-cooled nozzle at high speed, increasing the energy density and dissociation degree, forming a plasma arc.

Its stability, calorific value and temperature are higher than those of general arc, so it has greater penetration force and welding speed.

The gas forming the plasma arc and the shielding gas around it generally use pure argon.

According to the material properties of various workpieces, helium, nitrogen, argon or a mixture of both are also used.

Plasma arc cutting is a common cutting process for metal and non-metallic materials.

It uses high-speed, high temperature and high-energy plasma gas flow to heat and melt the material to be cut, and uses internal or external high-speed gas flow or water flow to discharge the molten material until the plasma gas flow beam penetrates the back to form a cut.

1. Micro plasma arc welding can weld foil and thin plate.

2. It has the small hole effect, and can better realize the free forming of single side welding and double sides.

3. The plasma arc has high energy density, high arc column temperature, and strong penetration ability.

The steel with a thickness of 10~12mm can be welded without groove.

It can be welded through once and formed on both sides.

The welding speed is fast, the productivity is high, and the stress deformation is small.

4. The equipment is complex, the gas consumption is large, the assembly clearance and the cleanliness of the workpiece are strict, and it is only suitable for indoor welding.

When plasma arc welding is used, DC current and sag characteristic power supply are usually used.

Due to the unique operating characteristics obtained from the special torch arrangement and the separate plasma and protective gas flow, an ordinary TIG power supply can be added to the plasma console, and a specially built plasma system can also be used.

It is not easy to stabilize the plasma arc when using sine wave alternating current.

When the distance between the electrode and the workpiece is long and the plasma is compressed, the plasma arc is difficult to play its role.

Moreover, in the positive half cycle, the overheated electrode will make the conductive nozzle spherical, thus interfering with the stability of the arc.

Special DC switching power supply can be used.

The duration of the positive electrode can be reduced by adjusting the balance of the waveform, so that the electrode can be fully cooled to maintain the shape of the tip nozzle and form a stable arc.

Friction welding is a welding method that uses the heat generated by the friction of the workpiece contact surface as the heat source to make the workpiece plastic deformation under pressure.

Under the action of pressure, it is under the action of constant or increasing pressure and torque that the relative motion between the welding contact end faces generates friction heat and plastic deformation heat on the friction surface and its surrounding areas, so that the temperature in and around the friction surface rises to a temperature range that is generally lower than the melting point.

The deformation resistance of the material decreases, the plasticity increases, and the oxide film at the interface breaks.

Under the action of upset forging pressure, with the plastic deformation and flow of materials, solid-state welding is realized through the molecular diffusion and recrystallization of the interface.

1. The welding quality of joints is good and stable.

The scrap rate of aluminum copper transition joints produced by low temperature friction welding in China is less than 0.01%;

The boiler factory adopts friction welding instead of flash welding to produce economizer coil, and the scrap rate of welding is reduced from 10% to 0.001%.

In West Germany, friction welding was used instead of flash welding to produce automobile exhaust valves, and the scrap rate of welding decreased from 1.4% to 0.04~0.01%.

As can be seen from the above examples, the scrap rate of friction welding is very low, about 1% of that of general welding methods.

2. Suitable for welding dissimilar steels and dissimilar metals.

Friction welding can not only weld ordinary dissimilar steels, but also weld dissimilar steels and metals with greatly different mechanical and physical properties at room temperature and high temperature, such as carbon structural steel high speed tool steel, copper – stainless steel, etc.

In addition, it can also weld the dissimilar metals that produce brittle alloys, such as aluminum copper, aluminum steel, etc.

3. High dimensional accuracy of weldments.

The maximum error of the full length of the diesel engine precombustion chamber produced by friction welding is ± 0.1mm.

Some special friction welding machines can ensure that the length tolerance of the weldment is ± 0.2mm and the eccentricity is less than 0.2mm.

Therefore, friction welding is not only used for welding blanks, but also for welding assembled finished products.

4. The welding machine has low power and energy saving.

Compared with flash welding, friction welding saves about 80~90% of electric energy.

5. Workplace sanitation of friction welding

There is no spark, arc light and harmful gas, which is conducive to environmental protection.

It is suitable for automatic production lines together with other advanced metal processing methods.

After years of development, friction welding technology has developed many classifications of friction welding: friction stud welding, friction surfacing, third body friction welding, embedded friction welding, inertial friction welding, friction stir welding, radial friction welding, linear friction welding and friction overlay welding.

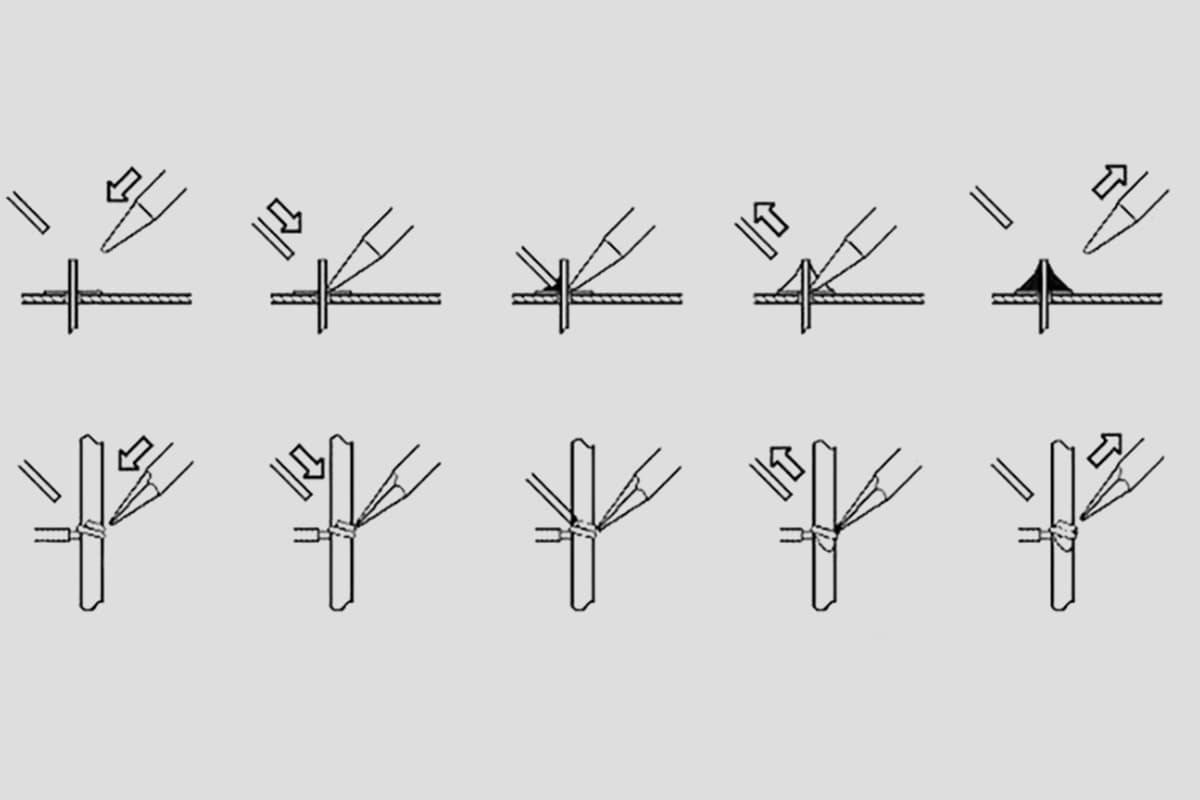

Spot welding refers to the welding method in which a welding spot is formed between the contact surfaces of two overlapping workpieces by using a cylindrical electrode during welding.

During spot welding, pressurize the workpiece to make it contact closely, then turn on the current, melt the workpiece contact under the effect of resistance heat, and form a welding spot after cooling.

Spot welding is mainly used for the welding of stamping parts of sheet components with a thickness of less than 4mm, especially for the welding of car bodies, carriages and aircraft fuselage.

However, vessels with sealing requirements cannot be welded.

Spot welding is a kind of resistance welding, which is mainly used for welding thin plate structure and reinforcement.

During spot welding, the weldment forms a lap joint and is pressed between the two electrodes.

Its main characteristics are as follows:

1. During spot welding, the heating time of the connection area is very short and the welding speed is fast.

2. Spot welding only consumes electric energy and does not require filler materials, flux, gas, etc.

3. Spot welding quality is mainly guaranteed by spot welding machine.

Simple operation, high mechanization and automation, and high productivity.

4. Low labor intensity and good working conditions.

5. Because the welding is powered on in a short time, requiring high current and pressure, the process program control is more complex, the welding machine has large capacitance, and the equipment price is higher.

6. It is difficult to carry out non-destructive testing on welding points.

Before welding, the surface of the workpiece shall be cleaned.

The common cleaning method is pickling, that is, pickling in sulfuric acid with a heating concentration of 10%, and then cleaning in hot water.

The specific welding process is as follows:

1. Put the workpiece joint between the upper and lower electrodes of the spot welder and clamp it;

2. Energize to heat the contact surface of two workpieces, locally melt and form nuggets;

3. Keep the pressure after power off, so that the nugget can be cooled and solidified under the pressure to form solder joints;

4. Remove the pressure and take out the workpiece.