Imagine trying to weld a material so strong that it resists wear and tear, yet so tricky that improper technique could lead to catastrophic failure. This is the challenge faced when welding quenched and tempered steels. In this article, you’ll discover the key characteristics of these materials, the specific welding methods and materials required, and crucial tips for pre- and post-welding treatments. By understanding these principles, you’ll learn how to achieve welds that maintain the steel’s remarkable strength and durability. Dive in to master the complexities of welding quenched and tempered steels.

Low carbon low alloy quenched and tempered steels are characterized by their high yield strength (450-980MPa), excellent ductility, toughness, and superior resistance to wear and corrosion. These properties can be tailored through precise alloy composition adjustments and optimized heat treatment processes to meet specific application requirements.

The weldability of these steels is generally superior to their medium carbon counterparts, primarily due to their lower carbon equivalent (CE) content, typically not exceeding 0.21%. This lower CE value contributes to reduced susceptibility to hydrogen-induced cracking and improved overall weldability. However, successful welding of these steels necessitates a thorough understanding of their unique welding characteristics, development of appropriate welding procedures, and strict adherence to established protocols.

The primary welding challenges associated with low carbon quenched and tempered steels include:

1. Cold Cracking Susceptibility: Despite their improved weldability, these steels remain prone to hydrogen-induced cold cracking, particularly in the heat-affected zone (HAZ). Mitigating this risk requires:

2. Reduced Toughness in the Coarse Grain HAZ: The high heat input during welding can lead to grain coarsening in the HAZ, potentially compromising toughness. This can be addressed by:

3. Hot Cracking Susceptibility: While generally less prone to hot cracking due to their low carbon and sulfur content and higher manganese-to-sulfur ratios, certain compositions may still be susceptible. Preventive measures include:

To ensure successful welding outcomes, it is crucial to:

The most commonly employed welding techniques for low carbon low alloy quenched and tempered steels include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), submerged arc welding (SAW), and gas tungsten arc welding (GTAW, also known as TIG welding). Each method offers distinct advantages depending on the specific application requirements.

When utilizing these arc welding processes with standard welding parameters, the cooling rate of the welded joint is relatively rapid. This accelerated cooling results in mechanical properties within the heat-affected zone (HAZ) of low carbon low alloy quenched and tempered steels that closely approximate the mechanical properties of the base metal in its quenched and tempered condition. This similarity in properties is crucial for maintaining the structural integrity and performance of the welded component.

Due to this favorable metallurgical response, post-weld heat treatment (PWHT) is typically not necessary for these steels when welded using the aforementioned methods. This elimination of PWHT can lead to significant time and cost savings in manufacturing processes.

For applications requiring precise control over heat input and weld bead geometry, such as in the fabrication of pressure vessels, the narrow gap dual-wire submerged arc welding process has proven highly effective. This advanced technique utilizes fine filler wires and maintains a relatively low heat input, which is particularly beneficial for preserving the carefully engineered microstructure of quenched and tempered steels. The reduced heat input minimizes the extent of the HAZ and helps maintain the desired mechanical properties throughout the welded joint.

When selecting a welding method for these steels, considerations should include:

When welding low carbon quenched and tempered steels, the selection of welding materials generally follows the principle of equal strength and is similar to the selection for hot rolled and normalized steels. Due to the increased susceptibility to cold cracking in low carbon quenched and tempered steels, strict control of hydrogen in the welding materials is crucial.

The welding electrode used for low carbon quenched and tempered steels should be of low hydrogen or ultra-low hydrogen type. Prior to welding, the electrodes must be dried according to the drying conditions specified by the manufacturer or the welding procedure specifications.

The dried electrodes should be immediately stored in a low-temperature and dry electrode holding oven for convenient access. Table 5-11 provides examples of welding electrodes for shielded metal arc welding, filler wires for gas metal arc welding, and shielding gases used for low carbon quenched and tempered steels.

Table 5-11: Examples of Welding Materials Selection for Low Carbon Quenched and Tempered Steels

| Welding method/Grade | Shielded Metal Arc Welding (SMAW) | Submerged Arc Welding (SAW) | Gas Metal Arc Welding (GMAW) | Shielded Metal Arc Welding (SMAW) |

| 14MnMoVN | J707 J857 | H08Mn2MoA H08Mn2NiMoVA In conjunction with HJ350 H08Mn2NiMoA In conjunction with HJ250 | H08Mn2SiH08Mn2Mo | |

| 14MnMoNbB | J857 | H08Mn2MoA H08Mn2NiCrMoA HJ350 | H10Mn2MoA H08Mn2Ni2CrMoA In conjunction with HJ360HJ431 | |

| WCF-62 | New 607CF CHE62CF(L) | H08MnSiMo Mn-Ni-Mo series |

(1) Pre-welding Preparation

Pre-welding preparation involves three aspects: preparation of welding groove, drying treatment of welding materials, and preheating.

1) Preparation of welding groove

Proper joint design, good groove processing, assembly, and welding quality are essential to ensure the excellent performance of low carbon low alloy quenched and tempered steels. When designing the joint, consideration should be given to the convenience of welding operations and post-weld inspections.

Incorrect placement of welds can lead to defects such as abrupt changes in cross-section, incomplete penetration, lack of fusion, undercut, and weld protrusion, as well as causing stress concentration.

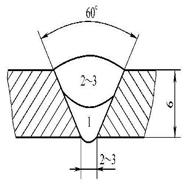

Generally, a butt joint is more suitable than a fillet joint as the latter has a higher stress concentration factor and significant notch effect. Additionally, butt joints are more convenient for radiographic or ultrasonic testing. U-shaped or V-shaped grooves are preferred, and double V-shaped or double U-shaped grooves can be used to reduce welding stress.

The grooves for low carbon low alloy quenched and tempered steels can be cut by gas cutting, but the hardened layer on the cut edge should be eliminated through heating or mechanical processing. When the plate thickness is less than 100mm, preheating is not necessary before cutting. For plate thicknesses ≥ 100mm, preheating at 100-150°C should be performed before cutting. For steels with higher severity levels, mechanical cutting or plasma arc cutting is preferred.

2) The welding materials should be dried according to the specified requirements

3) Preheating

In order to prevent cold cracking, preheating is often required when welding low carbon low alloy quenched and tempered steels. Generally, a relatively low preheating temperature (≤200°C) is used for welding low carbon low alloy quenched and tempered steels. When the preheating temperature is too high, it is not necessary for preventing cold cracking and can lead to significant embrittlement in the heat-affected zone. The minimum preheating temperature and interpass temperature for several low carbon low alloy quenched and tempered steels are listed in Table 5-12.

| Plate thickness (mm) Grade | <13 | 13~16 | 16~19 | 19~22 | 22~25 | 25~35 |

| 145MnMoNbB | – | 100~150 | 150~200 | 150~200 | 200~250 | 200~250 |

| 15MnMoVN | – | 50~100 | 100~150 | 150~200 | 150~200 | 150~200 |

(2) Welding Heat Input and Welding Technique

The welding heat input not only affects the performance of the heat-affected zone but also affects the performance of the weld metal. For many weld metals, a needle-like ferrite structure is required to achieve a combination of strength and toughness, and this structure can only be obtained under relatively fast cooling conditions. To avoid excessive heat input, it is not recommended to use large-diameter welding electrodes or filler wires.

Whenever possible, multi-pass narrow weld beads should be used instead of using the oscillation technique, as this not only improves the toughness of the heat-affected zone and weld metal but also reduces welding distortion. Carbon arc gouging can be used to clean the weld root, but strict control of the heat input is necessary. After carbon arc gouging, the gouged surface should be properly ground and cleaned before welding.

After welding a butt joint, it is necessary to grind down the excess height to ensure sufficient fatigue strength of the joint. Fillet joints tend to have stress concentration, which lowers the fatigue strength. Mechanical grinding, TIG re-melting, or hammer peening at the toe of the fillet weld can improve the fatigue strength of fillet joints, but the appropriate grinding, re-melting, or peening techniques must be selected.

(3) Post-Weld Heat Treatment

Most low carbon low alloy quenched and tempered steel welded components are used in the as-welded condition unless the following conditions require post-weld heat treatment:

1) Insufficient toughness of the steel after welding or cold working.

2) High precision machining is required after welding, and dimensional stability of the structure must be ensured.

3) The welded structure is subjected to stress corrosion.

In post-weld heat treatment of many precipitation-hardened low carbon low alloy quenched and tempered steels, stress relief cracks may occur in the heat-affected zone. To prevent the formation of stress relief cracks, measures such as lowering the annealing temperature, proper preheating, or post-weld heat treatment should be taken during welding.

(1) Performance of Medium Carbon Quenched and Tempered Steels

Medium carbon quenched and tempered steels have a higher carbon content (generally ranging from wC=0.25% to 0.50%) and contain various alloying elements such as Mn, Si, Cr, Ni, Mo, and B, V, Ti, Al, etc., to ensure hardenability and prevent temper brittleness. These steels exhibit excellent comprehensive properties in the quenched and tempered condition, with yield strengths ranging from 880 to 1176MPa.

However, the hardenability of these steels is relatively high, which affects the welding characteristics. 40Cr is a widely used chromium quenched and tempered steel known for its good mechanical properties and high hardenability. It has high fatigue strength and is commonly used in manufacturing important components that operate under alternating loads, such as gears and shafts encountered during welding.

35CrMoA and 35CrMoVA steels belong to the Cr-Mo steel system, which are medium carbon quenched and tempered steels with good strength and toughness matching. These steels are mainly used in the manufacturing of gas turbine impellers, main shafts, and generator rotors, among others.

(2) Welding Characteristics of Medium Carbon Quenched and Tempered Steels

Medium carbon quenched and tempered steels have different welding characteristics compared to low carbon low alloy quenched and tempered steels. After welding, the quenched microstructure of medium carbon quenched and tempered steels is hard and brittle high carbon martensite. They are highly sensitive to cold cracking, and if not subjected to post-weld heat treatment, the performance of the heat-affected zone may not meet the requirements of the original base metal.

Therefore, these steels are generally welded in the annealed state, and post-weld quenching and tempering treatment is required to obtain uniformly welded joints with the desired performance.

However, in some cases, welding in the quenched and tempered state is necessary, and the deterioration of the heat-affected zone performance in such cases is difficult to resolve. The application of medium carbon quenched and tempered steels in welded structures is not as widespread as that of hot rolled and normalized steels and low carbon quenched and tempered steels.

1) Embrittlement and Softening in the Heat-Affected Zone

Due to the higher carbon content and multiple alloying elements in medium carbon quenched and tempered steels, the starting temperature (Ms point) for the transformation from austenite to martensite is relatively low during rapid cooling. This results in the formation of high hardness martensite in the heat-affected zone, leading to embrittlement.

If the steel is welded in the quenched and tempered state without subsequent tempering treatment, the heat-affected zone is heated to a temperature above the tempering temperature, resulting in a softening zone with lower strength and hardness compared to the base metal. This softening zone can become a weak area that reduces the strength of the joint.

2) Welding Cracks

Medium carbon quenched and tempered steels have a high susceptibility to both hot cracking and cold cracking, and measures need to be taken to eliminate their contributing factors.

The heat-affected zone of medium carbon quenched and tempered steels is prone to the formation of hard and brittle martensite. They are highly sensitive to hydrogen-induced cold cracking.

To prevent the occurrence of hydrogen-induced cold cracking when welding medium carbon quenched and tempered steels, it is important to use low hydrogen or ultra-low hydrogen welding materials and welding processes. Preheating before welding and timely post-weld heat treatment are commonly used to prevent cold cracking.

Due to the high carbon and alloy element content in medium carbon quenched and tempered steels, there is a wide temperature range between the solidus and liquidus temperatures during the solidification of the weld pool.

This leads to a significant tendency for solidification cracking. To prevent the formation of solidification cracks, it is recommended to use welding materials with low carbon, low sulfur, and low phosphorus. In terms of welding technique, attention should be paid to fully filling the arc crater.

Commonly used welding methods for medium carbon quenched and tempered steels include tungsten inert gas (TIG) or helium arc welding, gas metal arc welding (GMAW), submerged arc welding (SAW), shielded metal arc welding (SMAW), and resistance spot welding.

Tungsten inert gas (TIG) or helium arc welding provides a low hydrogen content in the weld and is suitable for welding thin and highly constrained components. GMAW can use shielding gases such as CO2, Ar+CO2, or Ar+O2. GMAW produces welds with low hydrogen content, which helps reduce the possibility of cold cracking in medium carbon quenched and tempered steels.

SAW is commonly used for components that undergo post-weld tempering treatment. It is important to select the appropriate combination of wire and flux, using neutral or mildly basic fluxes to ensure that the post-weld heat-treated weld metal has satisfactory strength, ductility, and toughness.

Currently, SMAW is the most widely used welding method for medium carbon quenched and tempered steels. Low hydrogen or ultra-low hydrogen electrodes should be selected for SMAW. Several recommended electrodes are listed in Table 5-13.

1) Preparation of Grooves: The welding grooves for medium carbon quenched and tempered steels should be machined using mechanical methods to ensure assembly accuracy and avoid the formation of quenched microstructure caused by thermal cutting. Prior to welding, the base metal and welding materials should be thoroughly cleaned.

2) Drying of Electrodes and Flux: The electrodes and flux should be dried thoroughly before use, and measures should be taken to prevent moisture absorption during the welding process.

3) Preheating: In order to prevent hydrogen-induced cold cracking, except for thin-walled shells and other welded components with low restraint and simple structures, preheating is generally required when welding medium carbon quenched and tempered steels. The preheating temperature and interpass temperature can be controlled between 250 and 300°C.

(2) Determination of Welding Heat Input and Welding Technique

It is recommended to use lower heat input parameters for welding medium carbon quenched and tempered steels. High heat input will result in a wide and coarse-grained heat-affected zone, increasing the tendency for embrittlement. High heat input also increases the possibility of heat cracking in the weld and heat-affected zone. For components welded in the quenched and tempered state without subsequent tempering treatment, high heat input will increase the degree of softening in the heat-affected zone.

(3) Post-Weld Heat Treatment

To prevent hydrogen-induced cold cracking, post-weld heat treatment should be performed in a timely manner. If it is difficult to perform immediate tempering treatment, intermediate annealing or holding at a temperature above the preheating temperature can be done to eliminate diffused hydrogen and soften the heat-affected zone. Intermediate annealing also helps in stress relief.

1) A company manufactures a rich/lean absorption heat exchanger, with the main material being 16MnR. The longitudinal weld seam of the shell is a butt joint with an asymmetric X-shaped groove. Submerged arc welding is used, and the specific welding procedure is shown in Table 5-14.

| Welding Process Card for Joints | Number | ||

Joint Diagram | Base Material Material | 16MnR | 16MnR |

| Base Material Thickness | 14mm | 14mm | |

| Welding Position | Flat Welding | ||

| Welding Technique | Straight Welding, Multiple Pass Welding | ||

| Preheating Temperature | Room Temperature | ||

| Interlayer Temperature | ≤150℃ | ||

| Welding Sequence | |

| 1 | Check groove dimensions and surface quality |

| 2 | Clean the groove and surrounding area from oil and other dirt |

| 3 | Perform tack welding using the first layer welding process from the outside, with a length of 30-50mm |

| 4 | Weld inner layers 1-4 |

| 5 | Grind the root pass by carbon arc gouging from the outside, followed by grinding with a grinding wheel |

| 6 | Weld outer layers 5-7 |

| 7 | Clean slag and spatter after welding |

| 8 | Perform visual inspection |

| 9 | Perform non-destructive testing |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) | Remarks |

| 1 | SMAW | J507 | Φ4.0 | DCEP | 150~180 | 22~24 | 150~200 | |

| 2~7 | SMAW | J507 | Φ5.0 | DCEP | 180~210 | 22~24 | 160~220 |

3) For the same equipment mentioned above, the welding seam between the large header and the internal head is a corner joint. The material is 16MnR with a thickness of 82.5mm and 38mm. It requires a K-shaped groove and falls under the category of medium-thick plate welding.

The preheating temperature for the welding area and its vicinity should be 100℃. The interlayer temperature during the welding process should be maintained between 100-250℃. After welding, it needs to be heated to 620℃ and held for 2 hours for stress relief annealing treatment. Please refer to Table 5-16 for specific welding process details.

Table 5-16: Welding Process Card for K-shaped Groove Corner Joint

| Welding Process Card for Joints | Number | ||

Joint Diagram  | Base Material Material | 16MnR | 16MnR |

| Base Material Thickness | 82.5mm | 38mm | |

| Welding Position | Flat Welding | ||

| Welding Technique | Straight Welding, Multiple Pass Welding | ||

| Preheating Temperature | 100℃ | ||

| Interlayer Temperature | ≤100~250℃ | ||

| Welding Sequence | |

| 1 | Check groove dimensions and surface quality |

| 2 | Clean the groove and surrounding area from oil and other dirt |

| 3 | Perform tack welding using the first layer welding process from the outside, with a length of 30-50mm |

| 4 | Weld inner layers 1-6 |

| 5 | Grind the root pass by carbon arc gouging from the outside, followed by grinding with a grinding wheel |

| 6 | Weld outer layers 7-16 |

| 7 | Clean slag and spatter after welding |

| 8 | Perform visual inspection |

| 9 | Perform non-destructive testing |

| 10 | Perform post-weld heat treatment |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) | Remarks |

| 1 | SMAW | J507 | 1.0 | DCEP | 150~180 | 22~24 | 150~200 | |

| 2~16 | SMAW | J507 | 5.0 | DCEP | 180~210 | 22~24 | 160~220 |

4) A chemical machinery manufacturing plant is producing a liquid chlorine storage tank. The main material is 16MnDR with a thickness of 22mm. The welding seam is for the closure of the cylindrical body, using a butt joint with an asymmetric X-shaped groove.

The welding process involves a combination of shielded metal arc welding (SMAW) and submerged arc welding (SAW). After welding, it requires a heat treatment at 620℃ for 1 hour to eliminate stress. Please refer to Table 5-17 for specific welding process details.

Table 5-17: Welding Process Card for Asymmetric X-shaped Groove Butt Joint

| Welding Process Card for Joints | Number | ||

Joint Diagram | Base Material Material | 16MnDR | 16MnDR |

| Base Material Thickness | 22mm | 22mm | |

| Welding Position | Flat Welding | ||

| Welding Technique | Straight Welding Pass | ||

| Preheating Temperature | Room Temperature | ||

| Interlayer Temperature | ≤150℃ | ||

| Post-weld Heat Treatment | 620℃,1h | ||

Welding Sequence

| 1 | Check groove dimensions and surface quality, groove surface 100% magnetic particle testing (MT) |

| 2 | Clean the groove and surrounding area from oil and other dirt |

| 3 | Perform tack welding using the first layer welding process from the outside, with a length of 30-50mm |

| 4 | Weld inner layers 1-4 |

| 5 | Grind the root pass by carbon arc gouging from the outside, followed by grinding with a grinding wheel |

| 6 | Weld outer layers 5-6 |

| 7 | Clean slag and spatter after welding |

| 8 | Perform visual inspection |

| 9 | Perform non-destructive testing |

| 10 | Perform post-weld heat treatment |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) | Remarks |

| 1 | SMAW | J507GR | 4.0 | DCEP | 140~170 | 22~24 | 150~200 | |

| 2~4 | SMAW | J507GR | 5.0 | DCEP | 170~200 | 22~24 | 200~250 | |

| 5~6 | SAW | H10MN2 SJ101 | 4.0 | DCEP | 600~650 | 32~36 | 24~28m/h |

5) As mentioned earlier, for the welding seam between the top nozzle flange and the pipe of the liquid chlorine storage tank, a butt joint is required with single-sided welding and double-sided formation.

Tungsten inert gas (TIG) welding is used for back sealing, and shielded metal arc welding (SMAW) is used for filling and capping. The groove is a V-shaped groove without a blunt edge. After welding, stress relief treatment is performed. Please refer to Table 5-18 for the welding process details.

| Welding Process Card for Joints | Number | |||

Joint Diagram | Base Material Material | 16MnD | 16MnD | |

| Base Material Thickness | 6mm | 6mm | ||

| Welding Position | Flat Welding | |||

| Welding Technique | Straight Welding Pass | |||

| Preheating Temperature | Room Temperature | |||

| Interlayer Temperature | ≤150℃ | |||

| Post-weld Heat Treatment | 620℃,1h | |||

| Tungsten Electrode Diameter (mm) | Φ2.5 | Shielding Gas | Ar | |

| Nozzle Diameter (mm) | Φ16 | Gas Flow Rate (L/min) | 10 | |

| Welding Sequence | |

| 1 | Check groove dimensions and surface quality, groove surface 100% magnetic particle testing (MT) |

| 2 | Clean the groove and surrounding area from oil and other dirt |

| 3 | Perform tack welding using the first layer welding process from the outside, with a length of 5-10mm |

| 4 | Weld inner layers 1-3 |

| 5 | Perform visual inspection |

| 6 | Perform non-destructive testing |

| 7 | Perform post-weld heat treatment |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) | Remarks |

| 1 | GTAW | H10MnSi | 2.5 | DCEN | 80~120 | 10~12 | 50~80 | |

| 2~3 | SMAW | J507GR | 4.0 | DCEP | 140~170 | 22~24 | 140~180 |

A certain company is manufacturing the movable legs of a car crane, with material HQ80C. It uses a shielding gas mixture of argon and a welding wire of H08MnNi2MoA. Please refer to Table 5-19 for the welding process details.

| Welding Process Card for Joints | Number | ||

Joint Diagram | Base Material Material | HQ80C | HQ80C |

| Base Material Thickness | 16mm | 12mm | |

| Welding Position | Flat Welding | ||

| Welding Technique | Straight Welding Pass | ||

| Preheating Temperature | 100~125℃ | ||

| Interlayer Temperature | 100~125℃ | ||

| Shielding GasGas Flow Rate (L/min) | Ar+CO2(20%) | ||

| Shielding GasGas Flow Rate (L/min) | 10~15 | ||

| Welding Sequence | |

| 1 | Check groove dimensions and surface quality |

| 2 | Before assembly, perform shot blasting treatment to remove oxide scale, oil, and other dirt from the surface of the steel plate, groove, and surrounding area |

| 3 | Perform tack welding using the first layer welding process for positioning, with a length of 30-50mm |

| 4 | Weld the 4 inner corner welds, cleaning the root from the outside until the inner corner weld is exposed, then weld the outer corner welds |

| 5 | After welding, grind the welds and clean slag and spatter |

| 6 | Perform visual inspection |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) |

| 1 | MAW | H08MnNi2MoA | l.2 | DCEN | 120~150 | 18~22 | |

| 2~4 | MAW | H08MnNi2MoA | 1.2 | DCEN | 140~170 | 22-24 |

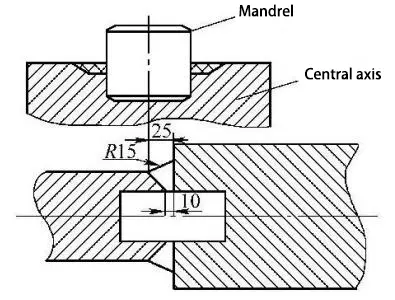

Repair of a broken shaft in a rolling mill, welding the shaft core to the intermediate shaft. The material is 37SiMn2MoV (similar to 42CrMo), and it is welded using shielded metal arc welding (SMAW) process. The welding electrode used is J607Ni. Please refer to the welding process details in the table.

| Welding Process Card for Joints | Number | ||

Joint Diagram | Base Material Material: 37SiMn2MoV (similar to 42CrMo) | 37SiMn2MoV | 37SiMn2MoV |

| Welding Position: Shaft core to intermediate shaft | Flat Welding | ||

| Welding Technique: Shielded Metal Arc Welding (SMAW) | Flat Welding | ||

| Preheating Temperature: As per welding procedure specifications | Straight Welding Pass, Multiple Passes with Multi-layer Pressure Welding | ||

| Interlayer Temperature: As per welding procedure specifications | 300℃, within a 300mm range of the welding area | ||

| Post-weld Heat Treatment: As per welding procedure specifications | 300-400℃ | ||

| Welding Sequence | |

| 1 | Check groove dimensions and surface quality, groove surface 100% penetrant testing (PT) |

| 2 | Clean the groove and surrounding area from oil and other dirt |

| 3 | Insert the shaft core into the intermediate shaft, and then place it in a pit-style heating furnace for preheating |

| 4 | During welding, ensure that the thickness of each layer of deposited metal is less than 2mm |

| 5 | Perform visual inspection |

| 6 | Perform hydrogen removal treatment at 350℃~400℃ for 2 hours. After sufficient insulation time, wrap the area within 300mm of the weld with insulation blanket |

| 7 | After cooling, perform liquid penetrant testing on the weld and surrounding base material, with no defects on the surface. After passing the inspection, process the end of the core shaft, assemble, and tighten after cooling. Apply uniform preheating to the area within 300mm of the weld, raising the temperature to 300℃. Welding requirements remain the same as mentioned above |

| 8 | Perform hydrogen removal treatment, following the same procedure as before |

| 9 | Perform stress relief treatment |

| 10 | Perform PT and UT testing |

Welding Specification Parameters

| Passes | Welding Method | Welding Material Grade | Welding Material Specification | Types of Current and Polarity | Welding Current (Ampere) | Arc Voltage (Volt) | Welding Speed (mm/per pass) | Remarks |

| 1 | SMAW | J607Ni | Φ4.0 | DCEP | 140~170 | 22~25 | 160~200 | |

| 2~3 | SMAW | J607Ni | Φ5.0 | DCEP | 170~200 | 22~25 | 180~220 |