What if you could ensure your welds are perfect every time? In this article, we’ll explore the welding process evaluation, a crucial method for testing and refining welding techniques. You’ll discover how to prepare, test, and evaluate welds to meet high-quality standards. Whether you’re involved in manufacturing or maintenance, understanding this process can enhance your welding efficiency and product reliability. Dive in to learn the essential steps and benefits of welding process evaluation.

Welding process evaluation is a critical preliminary phase in the overall welding operation, encompassing a comprehensive assessment of the proposed welding procedure’s suitability for specific weldments and related products. This systematic evaluation serves as a cornerstone for ensuring weld quality, reliability, and compliance with industry standards.

The evaluation process comprises several key stages:

Welding process evaluation is not merely a theoretical exercise but a crucial practical application in manufacturing. It is governed by specific prerequisites (such as material specifications and welding equipment capabilities), clearly defined objectives (e.g., achieving specific mechanical properties or corrosion resistance), and a limited scope tailored to the intended application.

The primary goal of this evaluation is to determine whether the welded joints produced using the proposed welding procedure meet or exceed all technical requirements and performance specifications. This includes assessing factors such as weld penetration, fusion, mechanical strength, ductility, and resistance to various types of failure modes relevant to the application.

Throughout the evaluation process, meticulous documentation is maintained, recording all welding process parameters, material data, equipment settings, environmental conditions, and test results. This comprehensive data set is then analyzed and synthesized into a formal “Welding Procedure Qualification Record” (WPQR) or “Welding Process Evaluation Report.” This document serves as a validated blueprint for future production welding, ensuring consistency, quality, and compliance with relevant codes and standards.

Welding process evaluation is a critical component in ensuring the quality and integrity of welded joints in boilers, pressure vessels, and pressure piping systems. This evaluation serves as an indispensable part of the technical preparation work, laying the foundation for successful welding operations in these high-stakes applications.

The significance of welding process evaluation is multifaceted:

To achieve these benefits, welding process evaluation employs a range of experimental techniques and analyses. These may include mechanical testing, non-destructive examination, microstructure analysis, and simulated service condition testing. The results of these evaluations provide concrete evidence of the welding process’s suitability and effectiveness.

The Welding Process Evaluation serves multiple critical functions in the manufacturing and maintenance of pressure-bearing equipment:

IV. Scope of Application of Welding Process Evaluation

Welding process evaluation is a critical quality assurance measure applicable to a wide range of industrial sectors, particularly in the fabrication, installation, and maintenance of critical steel equipment. This includes, but is not limited to, boilers, piping systems, pressure vessels, and load-bearing steel structures. Additionally, it plays a crucial role in welder training programs and technical assessments, ensuring the competency of welding personnel.

The evaluation encompasses various welding methods, each with its specific applications and challenges:

It is imperative to conduct welding process evaluation prior to commencing any welding operations to validate the proposed welding procedure specifications (WPS) and ensure they meet the required quality standards and project specifications.

The evaluation process is applicable across diverse industrial sectors, including but not limited to:

Welding process evaluation is inherently product-specific, recognizing that different products have unique technical requirements and quality standards. For instance:

The primary objective of welding process evaluation is to ensure that the welding procedure can consistently produce welds that meet or exceed the specific technical requirements of the product or structure. This includes considerations such as mechanical properties, corrosion resistance, and fatigue performance under the intended service conditions.

Furthermore, the evaluation process should take into account factors such as:

The welding process evaluation is a critical methodology aimed at resolving welding process challenges under specific conditions for any given steel material. Its primary objective is not to pinpoint optimal process parameters, but rather to provide a spectrum of solutions that are generally acceptable and applicable across a wide range of scenarios.

While the evaluation addresses performance issues within specific process conditions, it’s important to note its limitations. It cannot directly solve overarching quality concerns such as residual stress mitigation, deformation minimization, and the prevention of welding defects. These broader issues often require additional engineering controls and post-weld treatments.

A cornerstone of effective welding process evaluation is the thorough assessment of the raw materials’ weldability. Conducting reliable technical condition tests prior to production can serve as a valuable guide, circumventing the risky and often costly practice of using actual products as test pieces. This approach not only conserves resources but also provides a more controlled environment for evaluation.

During the evaluation process, it is crucial to isolate and exclude human factors to maintain objectivity. The assessment of welding processes should not be conflated with the evaluation of welder proficiency. Personnel responsible for conducting the welding process evaluation must possess the expertise to discern whether observed defects stem from process-related issues or skill-based shortcomings. In cases where skill deficiencies are identified, the appropriate response is targeted welder training rather than process modification.

Conventional welding process evaluation procedures typically rely on room temperature mechanical tests of welded joints. A joint that successfully passes visual inspection, non-destructive testing (NDT), and room temperature mechanical tests is generally deemed to have satisfied the welding process requirements. However, this standard battery of tests may not provide comprehensive reliability data for novel steel alloys used in high-temperature and high-pressure pipeline applications, particularly in the power generation industry. To ensure the integrity and longevity of these critical components, supplementary testing regimes should be considered. These may include high-temperature endurance tests to simulate operational conditions, creep tests to evaluate long-term deformation under constant stress, and stress corrosion tests to assess susceptibility to environmentally assisted cracking.

By incorporating these advanced testing methodologies, welding process evaluations can provide a more holistic assessment of joint performance, particularly for materials and applications that push the boundaries of traditional welding practices. This comprehensive approach not only enhances the reliability of the evaluation but also contributes to the overall safety and efficiency of welded structures in demanding industrial environments.

Compose and issue welding process evaluation assignment – Develop welding process evaluation plan – Weld and inspect test pieces – Prepare welding process evaluation report – Develop welding operation guide (or welding process card) based on the welding process evaluation report.

The main purpose of the assignment is to issue evaluation tasks. Therefore, its main content should include: purpose of evaluation, evaluation indicators, evaluation items, and qualification conditions of departments and personnel responsible for the evaluation tasks.

(1) Determine Evaluation Indicators

Technical indicators are determined based on the theoretical knowledge of regulations and steel (weldability), etc. According to the “Welding Process Evaluation Procedure” DL/T869, the chemical composition and mechanical properties (strength, plasticity, toughness, etc.) of the weld metal should be comparable to or not lower than the lower limit of the parent material.

(2) Determine Evaluation Items

Considering the actual work requirements of the project, cover related items according to the scope of the regulations, and determine the evaluation items. The determination of welding process evaluation items should consider the following aspects:

Steel:

(1) Classification of steel levels;

(2) Basic rules of steel grade levels in “evaluation”;

(3) Division of different types of steel. The meaning of the welding joint of different types of steel is:

The classification of different types of steel welding joints is primarily divided into two categories: one is those with the same metallographic structure but different chemical composition, such as the welding joint between low carbon steel and low alloy steel, both of which belong to the pearlite structure type with minor physical property differences but different chemical composition; the other category is those with different metallographic structures and chemical compositions and significant physical property differences, such as the welding joint between low alloy pearlite steel and high alloy martensitic steel or austenitic stainless steel.

The main feature of different types of steel welding joints is the uneven distribution of chemical composition, metallographic structure, mechanical properties, and welding residual stress. The welding process must address these issues and adopt necessary technological measures to resolve them.

①Type A different steel joints: One side of the welding joint is austenitic steel, and the other is other structured steel. Specific types include: A+M, A+B, A+P, and so on.

②Type M different steel joints: One side of the welding joint is martensitic steel, and the other is other structured steel. Specific types include: M+B, M+P, and so on.

③Type B different steel joints: One side of the welding joint is bainitic steel, and the other is pearlitic copper. There is only one type: B+P.

(1) Butt weld applicable to workpiece thickness

①When the evaluation test piece thickness is 1.5≤δ<8(mm), the range of applicable workpiece thickness is defined as: the lower limit is 1.5mm, the upper limit is 2δ, but not more than 12mm.

②When the evaluation test piece thickness is 8≤δ≤40(mm), the range of applicable workpiece thickness is defined as: the lower limit is 0.75 δ, the upper limit is 1.5δ. When the thickness of the evaluation test piece is more than 40mm, the upper limit is not restricted.

(2) Fillet weld applicable to workpiece thickness

The range of workpiece thickness applicable to the fillet joint thickness δ that has been evaluated is the same as the butt joint thickness, but the test piece thickness is calculated according to the following rules:

①The thickness of the plate-to-plate fillet weld test piece is the thickness of the web plate.

②The thickness of the tube-to-plate fillet weld test piece is the thickness of the tube wall.

③The thickness of the tube seat fillet weld test piece is the thickness of the branch tube wall.

In addition, for submerged arc welding double-sided welding and small diameter thick-walled, etc., check the regulations carefully and execute according to the regulations.

Each welding method should be assessed individually and cannot replace one another. If a combination of multiple welding methods is used for the “assessment,” each welding method can be “assessed” individually or in combination.

The thickness of the weld metal for each welding method should fall within the range of its own “assessment.” For instance, if the root layer is welded by TIG welding (thickness 3mm), and the filling and cover processes are carried out by stick welding (total thickness 8mm) for the welding process assessment (other conditions), this is considered as an assessment of the combination of two welding methods. The approved welding methods are suitable for:

(1) Individual TIG welding:

The assessed weld metal thickness is 3mm, with an applicable thickness range of (1.5~6)mm.

(2) Individual stick welding:

The assessed weld metal thickness is 8mm, with an applicable thickness range of (6~12)mm. The above-mentioned Ds/Ws welding methods can also be used separately for TIG welding and stick welding after passing the assessment, and then combined. The “assessment” of gas welding methods applies to the maximum thickness of the welded parts being the same as the “assessment” test piece thickness.

(1) The process approved by the “assessment” of the flat test pieces is applicable to tubular test pieces, and vice versa. However, various welding positions should be considered. For example, flat vertical welding can replace horizontal fixed tube welding, and vertical flat welding can replace vertical tube welding.

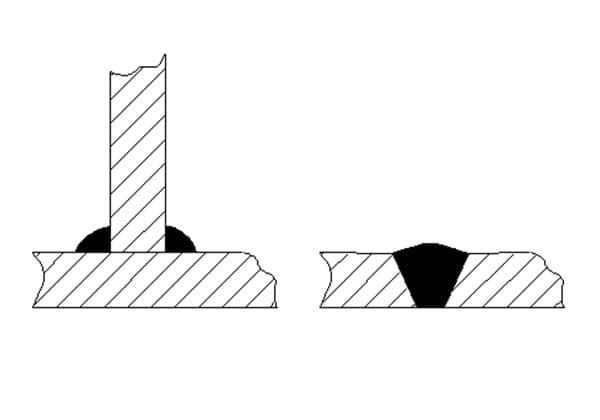

(2) The “assessment” of the butt joint test pieces applies to the corner joint test pieces.

(3) The “assessment” of the full penetration test pieces applies to the non-full penetration test pieces.

(4) The welding process approved by the “assessment” of the flat corner weld test pieces is applicable to the corner welds of the tube and plate or tube and tube, and vice versa.

(1) Welding materials such as welding rods, wires, and fluxes melt during the welding process and fuse into the weld metal in the form of filler metal. They are the main components of the weld metal. Their selection and change can significantly influence the weld properties of the weld joint.

However, their variety brings great difficulty to the “assessment.” To reduce the number of assessments and conduct them rationally, the selection of welding materials should follow the same principles as the selection of steel, divided by class level (refer to the table in the procedure), to facilitate the “assessment.”

(2) For foreign welding rods, wires, and fluxes, you can consult related materials or conduct tests to confirm their compliance before use. Their chemical composition and mechanical properties should be similar to those listed in the domestic welding material table. They can be classified into the corresponding class level and treated the same as domestic welding materials.

Welding rods, wires, and fluxes not listed in the welding material table, if their chemical composition, mechanical properties, and process characteristics are similar to those listed, can be classified into the corresponding class level and used. Those that cannot be classified should be “assessed” separately.

(3) Welding rods and wires of each category should be assessed separately. For those of the same category but different levels, the higher level’s assessment is applicable to the lower level; among the same level welding rods, those assessed with acidic welding rods can be exempted from basic welding rod assessment.

(4) The change of filler metal from solid wire to flux-cored wire, or vice versa.

(5) The change of combustible gas or shielding gas type, cancellation of backside shielding gas.

(6) The selection of materials for dissimilar steel welding should follow the principles of DL/T752.

(7) For foreign materials, especially welding materials for high alloy steel, you should fully understand the basic properties of the material. Some important indicators directly related to product performance should be verified through tests before use.

General guidelines do not strictly dictate the “evaluation” of pipe diameters. Due to the wide variety of pipe specifications in the power industry, the following provisions have been made considering significant process variations:

(1) When “evaluating” test pieces with an outer diameter Do of ≤60mm, and welding is done using the argon arc welding method, the process is applicable regardless of the outer diameter of the welded pipe.

(2) For other pipe diameters, the “evaluation” is applicable for welded pipe outer diameters ranging from lower limit 0.5D0 to an unspecified upper limit.

The power industry, taking into account specific industry characteristics, has made specific provisions for the “evaluation” of welding positions and their applicability (see table in guidelines). The following rules should also be adhered to in the following cases:

(1) In vertical welding, when the root weld changes from upward to downward welding or vice versa, a new evaluation should be conducted.

(2) For gas welding and tungsten electrode argon arc welding of pipes with a diameter of ≤60mm, unless there are special requirements for welding process parameters, only horizontal pipes are generally “evaluated”, which is applicable to all welding positions of the workpiece.

(3) During all-position automatic welding of pipes, tubular test pieces must be used for “evaluation”, and plate-shaped test pieces cannot be substituted.

When the preheating temperature of the evaluation specimen exceeds the intended parameters, a new evaluation should be conducted:

(1) When the preheating temperature of the evaluation specimen decreases by more than 50℃;

(2) For welded parts requiring impact toughness, when the interlayer temperature increases by more than 50℃.

(1) If an inspection is needed during the process, and the test piece cannot be welded in one go, post-weld heat treatment must be performed.

(2) The interval between the post-weld heat treatment and the completion of the welding operation should strictly follow the heat treatment specifications for various steels, and comply with the provisions of DL/T 819 and DL/T 868. For example, P91 martensitic steel requires that after welding is completed, the weld must cool to 100℃ before the austenite all turns to martensite, then the temperature is raised for post-weld heat treatment.

When changes occur in welding specification parameters and operating techniques, evaluation should be redone based on parameter type, or process instructions should be changed.

(1) In gas welding, changes in flame characteristics;

(2) In automatic welding, changes in the distance between the conductive nozzle and the workpiece;

(3) A change in welding speed greater than 10% of the evaluated value;

(4) Changing from single-side welding to double-side welding;

(5) Changing from manual welding to automatic welding;

(6) Changing from multi-pass welding to single-pass welding, etc.

These points and other special conditions can be considered collectively to determine how to identify welding process evaluation items.

1. The fabrication of test pieces must be conducted under effective supervision, strictly in accordance with the requirements and regulations of the process evaluation scheme.

2. There should be a dedicated person carefully recording each step during the welding process, and a parameter recorder capable of saving recorded data should be equipped. The records must be properly preserved for review.

3. The inspection items must be complete, conducted in accordance with the relevant regulations.

The main inspection items include:

(1) Weld seam appearance inspection: The remaining height of the weld metal should not be lower than the parent material, the depth and length of the undercut should not exceed the standard, and there should be no cracks, unfused areas, slag inclusions, arc pits or porosity on the weld surface.

(2) Non-destructive testing of weld seams: Radiographic inspection of tubular test pieces should be carried out in accordance with the requirements of DL/T821, and the quality of the weld should not be lower than level II standard. The non-destructive testing has no correlation with the mechanical properties of the welded joint, but understanding the welding defects in the “evaluation” is very necessary. Also, it should be considered to avoid these areas when cutting test pieces. Therefore, it should be included in the inspection items.

(3) Tensile test (dimensional specimens):

① The remaining height of the specimen is removed mechanically and leveled with the parent material.

② Specimen thickness: Full thickness specimens can be used when the thickness is less than 30mm. If the thickness is more than 30mm, it can be processed into two or more pieces of specimens.

③ The tensile strength of each specimen should not be less than the lower limit of the parent material.

④ The tensile strength of dissimilar steel specimens should not be less than the lower limit of the parent material on the lower side.

⑤ When two or more pieces of specimens are subjected to a tensile test, the average value of each group of specimens should not exceed the lower limit of the value specified by the parent material.

(4) Bend test:

① The bending specimens can be divided into transverse face bend (back), longitudinal face bend (back), and transverse side bend.

② When T is less than 10, T = t; when T is greater than t, t = 10. The width of the specimen: 40, 20, 10 (unit: mm).

③ The remaining height of the specimen is removed mechanically, the original surface of the parent material is retained, and the undercut and weld root notch cannot be removed.

④ The defect on the transverse side bend surface should be considered as the tensile surface.

⑤ The three main factors affecting the bend test are: the ratio of the width to the thickness of the specimen, the bending angle, and the diameter of the bending axis. The bending test method of the SD340-89 regulation and the related provisions do not correspond to the elongation of the material itself. Therefore, the elongation of the outer surface of the bending specimen has exceeded the lower limit of the elongation specified for some steels, which is not entirely reasonable.

For a more reasonable determination of plasticity in the bending test, the new regulation stipulates that the bending test method should be conducted according to GB/T232 Metal Bending Test Method.

The bending test conditions are specified as follows: the thickness of the specimen is less than equal to 10, the diameter of the bending axis (D) is 4t. The distance between the supports (Lmm) is 6t+3, and the bending angle is 180 degrees.

For steels with a specified elongation lower limit of less than 20% in the standard and technical conditions, if the bending test is not qualified, and the measured elongation is less than 20%, it is allowed to increase the diameter of the bending axis for the test.

After bending to the specified angle, there should be no cracks exceeding 3mm in length in any direction on the tensile surface of each piece of specimen, within the weld and heat-affected zone. Cracks on the edge are excepted, but cracks caused by slag inclusions should be counted.

(5) Impact test: For pressure-bearing and load-bearing components, as long as they meet the conditions for impact specimen, they should undergo an impact test. Therefore, it should be conducted when the following conditions are met:

① If the thickness of the weldment is not sufficient for sampling (5x10x5mm), it may not be required.

② When the thickness of the weldment is greater than or equal to 16mm, an impact test is required, 10x10x5mm.

③ Evaluation pass standard: The average value of three specimens should not be lower than the lower limit specified by the relevant technical documents, and one should not be lower than 70% of the specified value.

(6) Metallographic examination: The tubular corner joint should not have two inspection surfaces on the same cut.

(7) Hardness test: The hardness of the weld seam and the heat-affected zone should not be less than 90% of the hardness value, not exceed the Brinell hardness of the parent material plus 100HB, and not exceed the following specifications:

When the total alloy content is less than 3%, the hardness should be less than or equal to 270HB;

When the total alloy content is 3~10, the hardness should be less than or equal to 300HB;

When the total alloy content is greater than 10, the hardness should be less than or equal to 350HB;

For P91 steel 220~240 is optimal.

(8) The preparation, cutting and evaluation of the above specimens should be conducted according to the relevant standards.

(9) After inspection, a formal report must be issued by qualified personnel.

(10) The inspection procedures and requirements must comply with the regulations.