This article explores the fascinating world of welding, from manual arc welding to advanced gas-shielded techniques. You’ll uncover the methods, benefits, and applications of various welding processes. Get ready to learn how these essential techniques shape our modern world!

Welding is the process of joining the same metal or different metals.

After the welding operation, the polymer of metal and non-metal formed in a certain area is called weld seam.

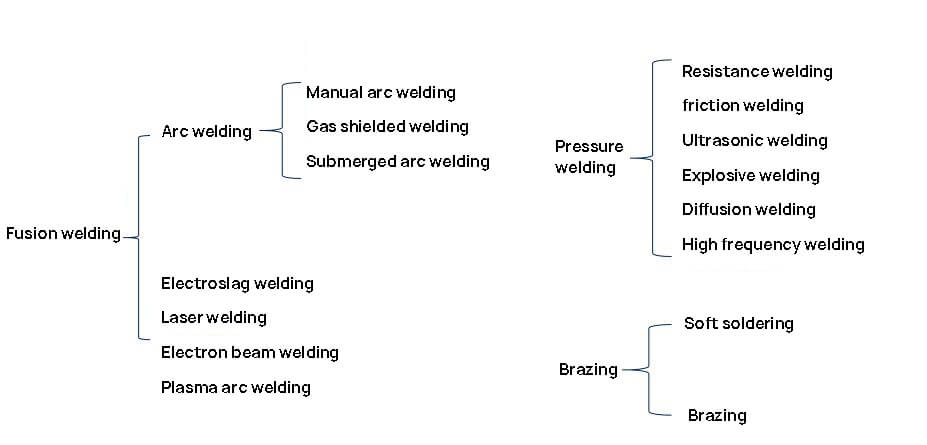

According to the characteristics of the welding process, it can be classified into fusion welding, pressure welding and brazing.

Fusion welding:

The welding method in which the metal at the joint is melted under the action of high temperature, etc.

Welding method completed under certain pressure.

Use the metal whose melting point is lower than the melting point of the base metal as the filler metal to heat the weldment and filler metal to the temperature between the melting point of the base metal and the melting point of the filler metal, so that the filler metal is liquid and wets the base metal, fills the joint gap and diffuses with the base metal to achieve welding.

Specific classification:

What is an arc?

The strong and lasting gas discharge between the workpiece and electrode is called arc.

To put it bluntly, it is just a gas discharge phenomenon.

However, the arc includes three parts: arc column area, cathode area and anode area.

Arc temperature:

Heat in arc zone:

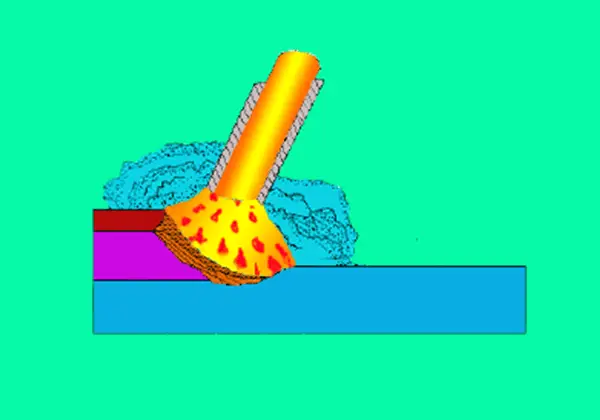

What is arc welding?

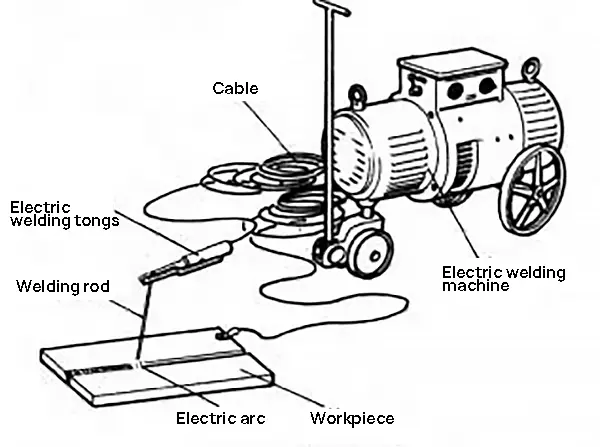

What is manual arc welding? To put it simply, arc welding is a welding method that uses arc combustion to provide heat source.

The electric arc welding method using manually operated welding rods is called manual electrode arc welding, which is called manual arc welding for short.

How is manual electrode arc welding performed?

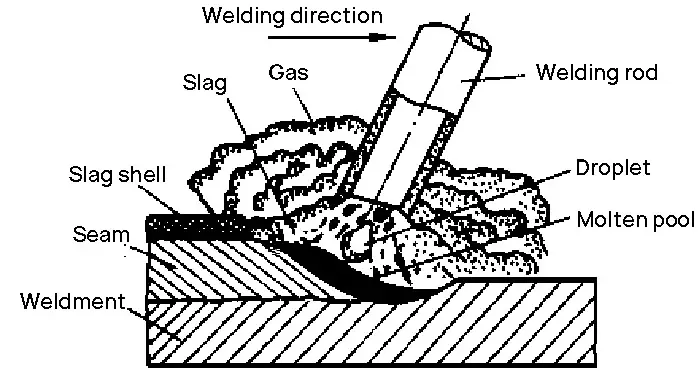

(1) The arc burns between the electrode and the weldment, and the heat of the arc makes the workpiece and the electrode melt into a molten pool at the same time;

(2) The electric arc melts or burns the coating of the electrode, producing slag and gas, which protect the molten metal and molten pool;

(3) When the arc moves forward, the subsequent molten pool cools and solidifies while new molten pool is continuously generated, thus forming a continuous weld.

Advantage of manual electrode arc welding:

Simple equipment, flexible operation and strong adaptability.

Disadvantage of manual electrode arc welding:

The production efficiency is low, the labor intensity is high, and the quality of welding joints is not easy to guarantee.

Application of manual electrode arc welding:

It can weld most metals, suitable for various welding positions, and can weld both thin and thick plates.

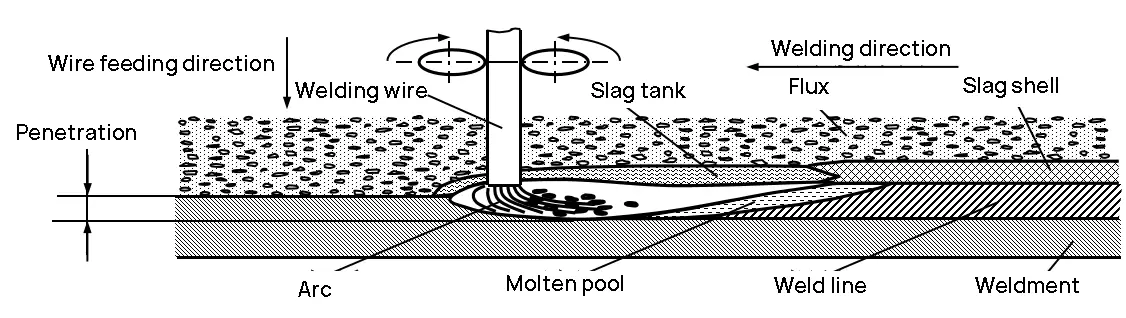

What is the commonly said submerged arc automatic welding?

Automatic welding – The welding action is automatically completed by the mechanical device.

Submerged arc welding – Welding in which an arc burns under a granular flux layer.

How does automatic submerged arc welding process?

(1) The flux flows out of the funnel and is evenly stacked on the welded part of the workpiece to form a flux layer (30-50mm);

(2) The continuously fed welding wire generates an arc between the welding wire and the weldment under the flux layer, melting the welding wire, workpiece and flux, forming a metal molten pool, and isolating them from the air;

(3) As the welding machine moves forward automatically, the arc continuously melts the metal, wire and flux of the weldment in front, while the edge behind the molten pool begins to cool and solidify to form a weld, and the liquid slag subsequently condenses to form a hard slag shell.

Why should a layer of flux be spread on the surface of the welding position?

It has the following three functions:

(1) Protective effect

Flux melts to form slag and gas, effectively isolating air, protecting droplet and molten pool, and preventing the burning of alloy elements;

(2) Metallurgical action

In the welding process, it plays the role of deoxidation and supplementing alloy elements;

(3) Improve welding process

Keep the arc burning steadily and make the weld beautiful.

What are the characteristics of automatic submerged arc welding?

What areas are they mainly used in?

Advantage of automatic submerged arc welding:

High production efficiency (5~times higher than manual arc welding);

Good welding quality (less porosity and slag inclusion);

Low cost (labor, time and material saving);

Good working conditions (no spatter, low labor force).

Disadvantage of automatic submerged arc welding:

Not suitable for welding complex welds and narrow spaces;

The equipment is complex and the required welding current is large (small current will cause unstable arc);

Poor adaptability (applicable to flat welding, long straight weld and circumferential weld with larger diameter).

Application:

It is used for long straight weld and circumferential weld with large diameter of production and medium plate structure, such as boiler, pressure vessel, ship, etc.

In order to obtain reasonable weld formation and good welding quality, as well as improve the welding speed, multi wire submerged arc welding has emerged.

It is widely used in applications requiring high welding efficiency, such as wind power, marine engineering, shipbuilding, pressure vessels, heavy machinery, pipelines and other industries.

Multi power series multi-wire submerged arc welding:

It is mainly used for pipeline welding.

According to the application, it can be divided into external welding of long straight longitudinal seam of pipeline, internal welding of long straight longitudinal seam of pipeline, external welding of spiral welded pipe, internal welding of spiral welded pipe and other different types.

Single power parallel multi-wire submerged arc welding:

Greatly improve the production efficiency, increase the welding speed, reduce the flux consumption, reduce the heat input and deformation, save energy, make the primer more efficient and cover more smoothly.

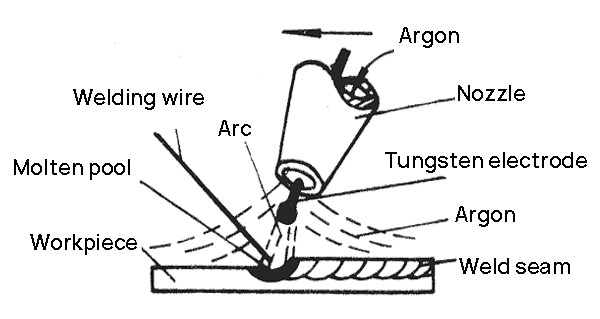

The arc welding using gas as the arc medium and protecting the arc and welding area is called gas shielded arc welding (GMAW).

In other words, gas shielded welding uses gas as the medium and protection.

What specific types does it have?

Classified according to whether the electrode is melted and the type of shielding gas:

Shielding gas:

Electrode:

Differences between consumable electrode and non consumable electrode gas shielded welding:

MIG/MAG: Directly feed the welding wire, which is both electrode and filler metal.

TIG: Tungsten electrode is the electrode and does not melt; The welding wire is fed separately and used only as filler metal

Argon arc welding

What are the characteristics of argon arc welding?

What are the main applications?

Tungsten electrode, manual wire feeding.

The welding wire is only the filler metal.

The welding wire does not pass the current, so there is no splash.

However, in order to avoid tungsten electrode melting and burning, which may cause tungsten contamination in the molten pool, the welding current is not easy to be too high.

Only thin plates less than 4mm can be welded.

Melting electrode, automatic wire feeding.

The welding wire is both an electrode and a filler metal.

There is no melting and burning loss of tungsten electrode.

The welding current can be adjusted in a wide range, so thin and medium-thick plates can be welded.

Advantage of argon arc welding

It can be welded in all directions;

Easy for observation and automatic control;

Good protection effect, stable arc and good welding quality;

It can weld almost all metals.

Disadvantage of argon arc welding

High argon cost;

The current density of argon arc welding is high, the light emitted is relatively strong, and the ultraviolet radiation generated by the arc is large, causing greater harm to the body;

The heat affected zone of argon arc welding is large, and the workpiece is prone to crack, pinhole, wear, scratch, undercut and other defects after repair;

Application of argon arc welding

It is mainly used for welding nonferrous metals and alloy steels that are easy to be oxidized (mainly welding of Al, Mg, Ti and their alloys and stainless steels).

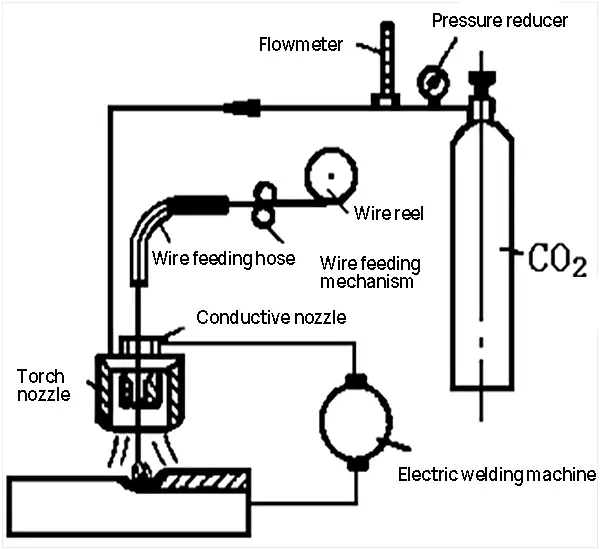

CO2 gas shielded arc welding

The principle of CO2 gas shielded arc welding is the same as that of MIG welding, except that the shielding gas is CO2.

The volume of CO gas in the molten pool and droplet expands rapidly and bursts, resulting in splashing.

It can oxidize metal and burn alloy elements, and can not weld nonferrous metals and alloy steel.

Advantage of CO2 gas shielded welding

Low cost (40%~50% of submerged arc welding and manual arc welding);

High efficiency (high current density, large penetration and fast welding speed);

Good welding quality (air flow cooling, small heat affected zone, small deformation);

Able to weld in all positions.

Disadvantage of CO2 gas shielded welding

Poor weld formation and large spatter;

Burn out alloy elements, easy to produce pores;

Poor wind resistance during welding, suitable for indoor operation.

Application of CO2 gas shielded welding

It is applicable to the welding of low carbon steel and low alloy steel sheet (0.8~4mm).

The welding wire containing deoxidizer must be used, and the DC connection must be reversed;

In addition, there shall be no wind during welding, and indoor welding is preferred.

Electric slag welding is a welding method that uses the resistance generated by the current passing through the slag to heat melt the welding wire and base metal to form a weld.

As for how electroslag welding is carried out, please see the following analysis:

(1) At the beginning, short-circuit the welding wire and the starting groove for arc starting;

(2) Continuously add a small amount of solid flux to melt it with the heat of the arc to form liquid slag;

(3) When the molten slag reaches a certain depth, increase the feeding speed of the welding wire and reduce the voltage, so that the welding wire is inserted into the slag pool and the arc is extinguished, thus turning into the electroslag welding process.

What are the characteristics of electroslag welding?

For what welding fields?

Advantage of electroslag welding

High productivity, no need to consider the thickness of weldment;

Few weld defects and good welding quality;

No groove is required, and the cost is low.

Dis advantage of electroslag welding

The heat input is large, and it is easy to overheat near the weld;

The weld metal has coarse crystalline as cast structure and low impact toughness;

The weldment shall be subject to normalizing and tempering heat treatment after welding.

Application of electroslag welding

It is applicable to vertical welding and welding of 40~450mm thick plates, generally used for straight seam or circumferential seam welding, thick plate splicing, vertical welding of blast furnaces in steel plants, welding of large castings, forgings, etc.

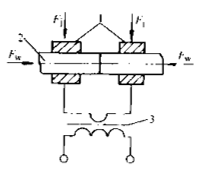

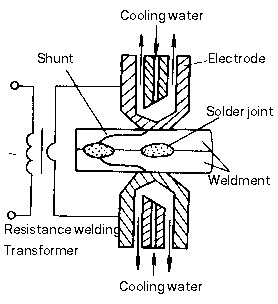

To put it simply, the welding under pressure using resistance heat as the welding heat source is called resistance welding.

Advantage of resistance welding

Low welding voltage, high current and high productivity;

Low cost, no need for filler metal and other welding materials,

The welding deformation is small, and there is no need for correction and heat treatment after welding;

Good working conditions, simple operation, easy to realize automatic production.

Disadvantage of resistance welding

The welding equipment is complex and the investment is large;

There are certain restrictions on the thickness of weldment and joint form;

At present, there is no simple and reliable nondestructive testing method.

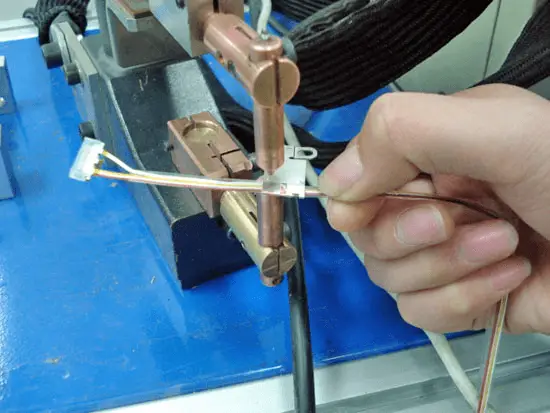

Resistance welding can be divided into spot welding, seam welding and butt welding.

Spot welding

Seam welding

Resistance butt welding

Flash butt welding

1. Spot welding

Spot welding diagram

The weldment is assembled as a lap joint, and the cylindrical electrode is pressurized and energized to generate resistance heat to melt the weldment metal and form nuggets (welding spots).

Spot welding process and shunting phenomenon

Spot welding process: compression → power on (nugget formation) → power off (freezing) → removal pressure

Shunt phenomenon: when welding the second point, the existing welding point will conduct current, causing power loss. The current at the welding point is reduced, which affects the welding quality.

Prevent shunt: there should be a certain distance between two welding points.

The distance between two adjacent welding heads shall not be too small, and the minimum point distance is shown in the following table.

| Workpiece thickness/mm | Point pitch/mm | ||

|---|---|---|---|

| Structural steel | Heat-resisting alloy | Aluminium alloy | |

| 0.5 | 10 | 8 | 15 |

| 1.0 | 12 | 10 | 15 |

| 1.5 | 14 | 12 | 20 |

| 2.0 | 16 | 14 | 25 |

| 3.0 | 20 | 18 | 30 |

| 4.0 | 24 | 22 | 35 |

Application of spot welding

It is mainly used for sheet metal stamping structure and reinforcement components;

It is applicable to the welding of overlapping structural parts of thin plates with sealing requirements or high joint strength requirements, such as oil tank, water tank, etc.

2. Seam welding

The weldment is assembled into overlapping or diagonal joints and placed between two roller electrodes.

The roller pressurizes the weldment and rotates to drive the weldment to move forward.

The weldment is powered continuously or intermittently, and the weldment metal is melted by resistance heat to form a series of welding points.

Classification of seam welding

| Form | Electric current | Electrode | Characteristic | Application |

| Continuous seam welding | Continuous conduction | continuous spin | Simple equipment and high productivity, but electrode wear is serious. | Small power welding non important structure (cylinder making, barrel, etc.) |

| stitch-and-seam welding | Intermittent continuity | continuous spin | Wide application (ferrous metal) | |

| Step seam welding | Intermittent continuity | Intermittent rotation | Complex equipment, high requirements, low electrode wear and high welding quality. | It is mainly used for seam welding of magnesium and aluminum alloys. |

Characteristic of seam welding

Solder joints overlap each other and flow diffluence is serious.

The current is about 1.5~2.0 times of that of spot welding;

The pressure is about 1.2~1.6 times of that of spot welding;

Therefore, high-power welding machine is required.

Apply pressure and use the roller as the electrode.

Application of seam welding

Seam welding is mainly used for thin-walled structures with regular weld seams and a thickness of less than 3mm and with sealing requirements;

Such as aircraft and automobile fuel tanks, various containers, steel radiators, etc.

3. Butt welding

A type of resistance welding method that uses resistance heat to weld two workpieces together along the entire end face is called butt resistance welding, or butt welding for short.

Butt welding can be divided into resistance butt welding and flash butt welding.

3.1 Resistance butt welding

Resistance butt welding refers to the method of pressing the end faces of two workpieces all the time, heating them to plastic state with resistance heat, and then rapidly applying upset pressure (or only maintaining the pressure during welding without upset pressure) to complete welding.

Characteristic of resistance butt welding

Simple operation and symmetrical joint shape;

The requirements for welding surface cleaning before welding are high;

The end face processing requirements are high, otherwise the welding quality is difficult to ensure.

Application of resistance butt welding

It is suitable for welding low-carbon steel bars and pipes with compact welding section, low strength requirements, diameter (or side length) less than 20mm, or non-ferrous metal bars and pipes less than 8mm (welding of rod shaped parts with similar end face shape and size).

3.2 Flash butt welding

The weldment is assembled as a butt joint, the power is connected, and its section is gradually moved closer to local contact.

The metal in the section is melted and flies out under resistance heating, forming a flash.

When the end reaches the predetermined temperature within a certain depth range, the upsetting force is rapidly applied to complete the welding.

Process: pressurization — energization — flash — upset forging

Characteristic of flash butt welding

Less slag inclusion in the joint, good welding quality and high joint strength;

The requirements for cleaning the end face of the weldment before welding are not strict;

Flash butt welding has large metal loss, and the joint burrs after welding need to be processed and cleaned. The labor conditions are poor.

Application of flash butt welding

In principle, all metal materials that can be cast can be welded by flash butt welding.

For example, low carbon steel, high carbon steel, alloy steel, stainless steel;

Aluminum, copper, titanium and other non-ferrous metals and alloys;

It can also weld dissimilar alloy joints.

(Soldering iron brazing)

(Flame brazing)

(Induction brazing)

Use the metal with a melting point lower than the weldment as the filler metal, heat the weldment (base metal) and filler metal to a temperature higher than the melting point of the filler metal and lower than the melting temperature of the base metal, melt and wet the base metal, fill the joint gap, and diffuse with the base metal to form a welded joint, which is called brazing.

Brazing process

Solder melting — liquid solder flowing into joint gap — mutual diffusion between solder and base metal — filling gap — forming joint after solidification

Characteristics of brazing

1) The melting point of the filler metal is lower than that of the base metal, and the base metal will not melt during brazing;

2) The composition of filler metal and base metal is very different;

3) The melted filler metal is sucked in by wetting and capillarity and kept in the base metal gap;

4) Metallurgical bonding is formed by mutual diffusion between liquid solder and solid base metal.

Advantage of brazing

The structure and properties of the base metal do not change (the base metal does not melt, only the filler metal melts);

Simple equipment, less production investment;

The heating temperature is low, the deformation is small, and the joint is smooth;

High productivity, can weld multiple weldments and joints at the same time;

It can be used to weld dissimilar metals or dissimilar materials, with no limit on the thickness difference of the workpiece.

Disadvantage of brazing

The brazed joint has low strength and poor heat resistance.

Classification of brazing

| Type/characteristic | Soft soldering(tin, lead solder) | Brazing(Copper based and silver based solders) |

| Solder melting point | ≤ 450℃ | > 450℃ |

| Performance Characteristics | Joint strength ≤ 100MPa, low working temperature | Joint strength > 200MPa, high working temperature |

| Application | It is used for welding instruments and conductive components with little stress. | It is used for welding of components, tools and tools with large force. |

Application of brazing

It is mainly used for manufacturing precision instruments, electrical components, dissimilar metal components and welding of complex sheet structures, such as sandwich components, honeycomb structures, etc.

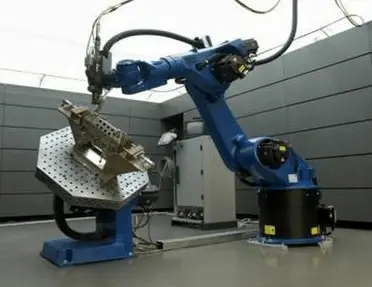

2.2.1 Friction welding

Friction welding is a pressure welding method that uses the heat generated by the friction between the surfaces of the weldment to make the end face reach the thermoplastic state, and then rapidly upsets to complete the welding.

Friction stir welding

Continuous drive friction welding

Inertia friction welding

Welding process of friction welding:

1) Relative movement of weldment;

2) The end face contact between the two weldments produces friction heat;

3) When the section reaches the thermoplastic state, press the top section quickly to complete the welding.

Advantage of friction welding:

High welding productivity, 5-6 times higher than flash butt welding;

Stable welding quality and high dimensional accuracy of weldments;

Low processing cost, power saving, no need for special cleaning of weldments;

Easy to realize mechanization and automation, simple operation;

No spark, arc and harmful gas.

Disadvantage of friction welding:

Large investment;

It is difficult to weld non-circular sections and the welding area is limited.

Application of friction welding:

It can be used for welding the same or different metal and different steel products, such as copper aluminum transition joints in the electric power industry, high-speed steel structural steel tools for metal cutting, serpentine pipes, valves, tractor bearings, etc.

2.2.2 Laser welding

The surface to be machined is heated by laser radiation, and the surface heat is directed to the internal diffusion through heat transfer to melt the workpiece and form a specific molten pool. The weld is formed after the molten pool solidifies.

Advantage of laser welding:

High welding speed and efficiency;

High welding precision, small deformation and easy automatic control;

No electrode is needed, so there is no electrode pollution.

Disadvantage of laser welding:

Large investment, small power, and limited weldable thickness;

It is difficult to align the welding point with the laser beam gathering area;

Rapid solidification of the weld bead may cause porosity.

Application of laser welding:

It is mainly used for welding parts in precision manufacturing fields such as aerospace, shipbuilding, automobile and electronic industry.

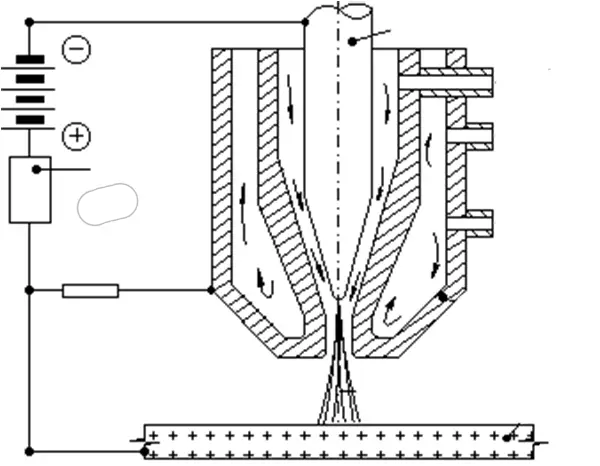

2.2.3 Plasma arc welding

What is a plasma arc?

How is plasma arc welding performed?

To put it simply: the arc in which the arc column is compressed and the energy is highly concentrated, and the gas in the arc column is fully ionized, is called plasma arc, also called compression arc.

The gas is heated by the arc and initially ionized. When it passes through the water-cooled nozzle at high speed, it is compressed, increasing the energy density and ionization degree, and forming a plasma arc.

Because of the high heat and penetration force of the plasma arc, the workpiece at the welding point is melted to form a molten pool, so as to realize the welding of the workpiece.

Advantage of plasma arc welding:

High energy density, strong arc directivity and strong penetration ability;

The depth width ratio of the weld is large, and the heat affected zone is small;

Stable arc combustion (stable even when the current is small);

The welding cost is low, and when the welding thickness is small, there is no groove and no need to fill wire;

It has stable keyhole effect, and can better realize the free forming of single side welding and double sides.

Disadvantage of plasma arc welding:

Equipment is expensive;

Poor observability of arc action area;

The weldable thickness is limited (generally less than 25mm).

Application of plasma arc welding:

It is widely used in industrial production, especially in the welding of copper and copper alloys, titanium and titanium alloys, alloy steel, stainless steel, molybdenum and other metals used in military and cutting-edge industrial technologies such as aerospace, such as titanium alloy missile shells, and some thin-walled containers on aircraft.

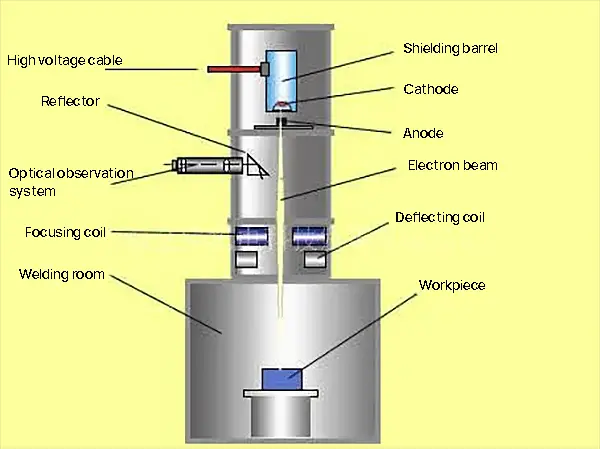

The method of welding by using the heat energy generated by the accelerated and focused electron beam bombarding the weldment placed in vacuum or non vacuum is called electron beam welding.

In other words, the heat required for welding is generated by electron beam bombarding the weldment.

Welding process:

1) The cathode of the electron gun emits electrons due to direct or indirect heating;

2) Under the acceleration of high-voltage electrostatic field, the electron beam with high energy density can be formed by focusing the electromagnetic field;

3) The high-energy density electron beam bombards the workpiece, and the huge kinetic energy is converted into heat energy to melt the weldment, forming a molten pool, and then complete the welding.

Advantage of electron beam welding:

Fast welding speed and high efficiency;

No groove, no welding wire, no flux, etc;

Low energy consumption, narrow heat affected zone, small welding deformation and excellent quality;

The penetration ability of electron beam is strong, and the depth width ratio of weld is large, which can reach 50:1.

Disadvantage of electron beam welding:

The equipment is complex and expensive;

The size and shape of weldments are often limited by the vacuum chamber;

The electron beam is easily interfered by stray electromagnetic field, which affects the welding quality.

Vacuum electron beam welding

Application of electron beam welding:

Suitable for fine welding of refractory metal, active metal and high purity metal.

It is widely used in the welding of nuclear energy, aviation, aerospace, automobile, pressure vessel, tool manufacturing and other industrial fields.

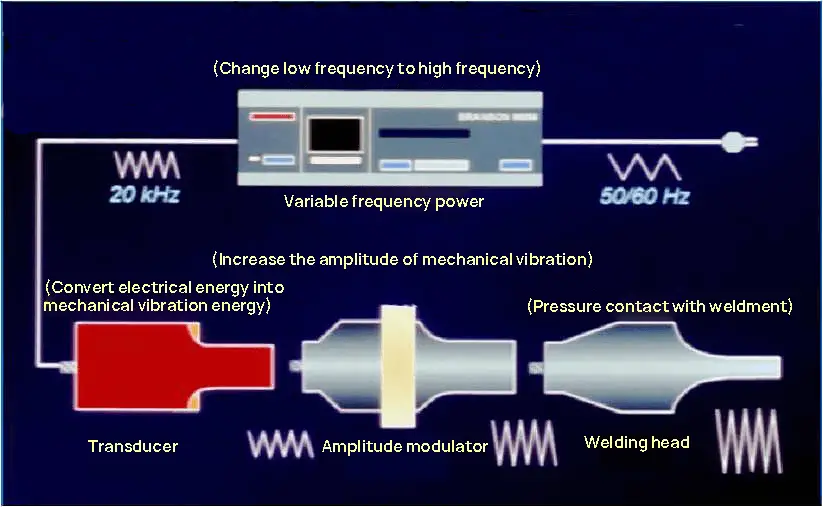

Ultrasonic welding is a method that uses the high-frequency oscillation of ultrasonic wave to locally heat and clean the workpiece joint, and then applies pressure to realize welding.

Welding process

1) Low frequency alternating current to high frequency alternating current;

2) Electric energy is converted into mechanical vibration energy;

3) Increase amplitude;

4) Apply pressure, and the welding head contacts the workpiece for welding.

Advantage of ultrasonic welding:

Easy operation, fast welding speed and high production efficiency;

The requirements for the cleanliness of the workpiece surface are not high;

It is not necessary to add any binder, filler or solvent.

Disadvantage of ultrasonic welding:

It is only applicable to the welding of thin parts such as wire, foil, sheet, strip and strip;

In most cases, the joint form can only be lap joint.

Application of ultrasonic welding:

It is applicable to the welding of high conductivity, high thermal conductivity materials and a variety of composite materials, and is widely used in the welding of microelectronic devices and finishing fields.

High frequency welding is a method that uses the resistance heat generated by high-frequency current in the workpiece to heat the surface layer of the welding area of the workpiece to a molten or near plastic state, and then applies (or does not apply) upset force to achieve metal bonding.

Skin effect: When the conductor is connected with AC current, most of the current flows only along the surface of the conductor.

Proximity effect: When high-frequency current flows in opposite directions between two conductors or in a reciprocating conductor, the current will concentrate on the flow near the conductor.

To put it simply, the skin effect is “the current goes to the surface”; Proximity effect is “current shortcut”.

Advantage of high frequency welding:

High welding speed and efficiency (the current is highly concentrated in the welding area);

A wide range of weldable materials can also be used to weld dissimilar metals;

Cleaning before welding is simple (fusion welding, with pressure effect, does not need to clean the joint surface).

Disadvantage of high frequency welding:

The joint assembly accuracy is required to be high;

High voltage and high frequency current are harmful to human body and other equipment.

Application of high frequency welding:

It is suitable for welding carbon steel, alloy steel, stainless steel, copper, aluminum, titanium and other dissimilar metals.

It is widely used for welding the longitudinal seam or spiral seam when manufacturing pipes.

Diffusion welding refers to the welding method of closely fitting the weldment, keeping it under a certain temperature and pressure for a period of time, and making use of the mutual diffusion of atoms between the contact surfaces to form a connection.

Welding process

a) Rough initial contact

b) Phase I: deformation and interface formation

c) Phase II: grain boundary migration and micropore elimination

d) Phase III: volume diffusion, micropore elimination

Physical welding display

Advantage of diffusion welding:

Multiple joints can be welded at one time;

The joint quality is good, and no machining is required after welding;

Small deformation of weldment (low pressure, overall heating of workpiece, cooling in furnace).

Disadvantage of diffusion welding:

Large investment and high cost;

Long welding time, time-consuming and labor-intensive surface preparation, and low productivity;

There is no reliable nondestructive testing method for weld quality.

Application of diffusion welding:

It is applicable to the welding of various dissimilar materials, special materials and special structures, and is widely used in aerospace, electronics, nuclear power and other industrial fields.

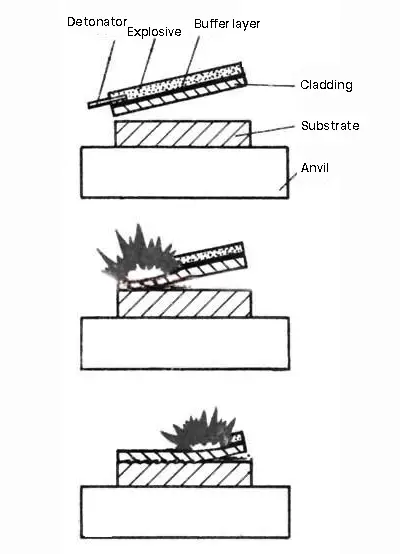

Explosive welding is a method to realize welding by using the impact force generated by explosive explosion to cause rapid collision of workpieces.

Explosive welding is also a kind of pressure welding.

For welding of small workpieces, both parallel method and angle method can be used;

The parallel method is often used for large area welding.

The gap between the front sections of the two plates is too large, which will lead to excessive acceleration of the clad plate and excessive impact energy, resulting in damage and crack at the edge of the plate, thus reducing the effective area of the clad plate and consuming the plate.

Advantage of explosive welding:

Small investment and low cost;

Especially suitable for dissimilar metals and large area welding;

The process is simple, no complex cleaning is required, and the application is convenient.

Disadvantage of explosive welding:

It can only be used for welding of plane or cylinder structure;

Open air operation has low mechanization and affects the environment.

Application of explosive welding:

Suitable for welding dissimilar metals, such as aluminum, copper, titanium, nickel, tantalum, stainless steel and carbon steel, aluminum and copper welding.

It is widely used for the welding of conductive bus transition joints, heat exchanger tubes and tube sheets, and the manufacture of large-area composite plates.

What is welding material?

The general name of the materials consumed during welding is called welding materials; such as welding rod, welding wire, metal powder, welding flux, gas, etc.

Common welding materials

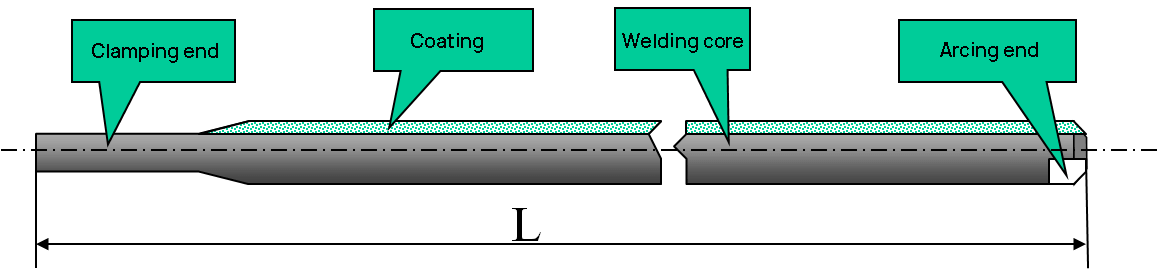

The electrode used in arc welding, which is coated with a protective coating, is referred to as the “electrode.”

The electrode is made up of a welding core and a coating.

The core of the electrode, covered by the coating, is referred to as the welding core.

The welding core serves dual purposes: as an electrode that conducts current, and as a filler metal that joins with the melted base metal to create the weld.

The coating is a layer applied to the surface of the welding core after the raw materials, such as ore powder, ferroalloy powder, organic matter, and chemical products, have been prepared in a specific proportion.

Coating function:

1) Mechanical Protection (Combined Gas and Slag Protection)

Gas and slag are used to shield the air and prevent contact between the molten droplets, the molten pool metal, and the air.

The solidified slag forms a protective layer over the weld surface, which helps to prevent oxidation and nitriding of the high-temperature weld metal.

2) Metallurgical Treatment (Deoxidation, Dephosphorization, Desulfurization, Alloying)

This process removes harmful elements and adds alloying elements.

3) Improving Welding Process Performance (Arc Stabilization)

The electric arc ignites easily and burns steadily, resulting in less spatter, a better-looking weld shape, and slag that is easy to remove. This process is suitable for all welding positions.

Composition of coating:

| Name | Effect | Common raw materials |

| Arc stabilizer | Contains materials that are easy to ionize, improving the stability of the arc | Potassium carbonate, marble, sodium silicate, feldspar, rutile, etc |

| Investigational agent | Formation of slag to protect the melter and bath | Ilmenite, rutile, marble, quartzite, mica, etc |

| Gasifier | Generate gas and isolate the air to protect the welding area | Organic matter (such as starch, dextrin, sawdust, etc.) and carbonate (marble, dolomite, etc.) |

| binder | Make each component of the coating bond and bond around the core | Sodium silicate, potassium sodium silicate |

| Deoxidizer | Reduce the oxidizability of coating and slag, and remove oxygen from metal | Ferromanganese, ferrosilicon, ferrotitanium and aluminum |

| Alloying agent | The elements that compensate for the loss can obtain the necessary ingredients to make the drug skin have certain plasticity, elasticity and flow | Ferroalloy or metal powder, such as ferromanganese, ferrosilicon, ferromolybdenum, ferrotitanium, etc |

| Formant | The coating has certain plasticity, elasticity and fluidity, which is convenient for electrode pressing, and makes the surface smooth without cracking | White mud, mica, titanium dioxide, dextrin, etc |

What are the types of welding rods?

1) Classification by slag alkalinity

a. Acid electrode

Characteristic:

(1) There are several oxide acids present in the drug skin, including FeO, SiO2, and TiO2, among others.

(2) The processability is good, and the weld formation is attractive with fine ripples.

(3) The slag exhibits strong oxidation.

(4) It works with both AC and DC power.

b. Basic electrode (low hydrogen electrode)

Characteristic:

(1) The skin of the drug contains higher levels of alkaline oxides, such as marble (CaCO3) and fluorite (CaF2).

(2) During welding, CO2 and HF are produced, which decreases the hydrogen content in the weld, earning it the nickname “low hydrogen electrode.”

(3) The weld is characterized by its high plasticity and toughness, although its processability and shape are not as good as those of the acid electrode. Typically, a DC reverse connection is used.

2) Classification according to the use of welding rods

Structural steel electrodes, heat-resistant steel electrodes, stainless steel electrodes, surfacing electrodes, low temperature steel electrodes, cast iron electrodes, nickel and nickel alloy electrodes, copper and copper alloy electrodes, aluminum and aluminum alloy electrodes, and special-purpose electrodes.

3) Classification according to chemical composition of drug skin

Titanium Oxide Electrode, Calcium Titanate Electrode, Ilmenite Electrode, Iron Oxide Electrode, Cellulose Electrode, Low Hydrogen Electrode, Graphite Electrode, and Base Electrode.

The type of welding rod is determined based on the national standard for welding rods, and it is a means of expressing the primary characteristics of the reaction welding rod.

The model of welding rod includes the following meanings: type of welding rod, characteristics of welding rod (type of core metal, service temperature, chemical composition of deposited metal, tensile strength, etc.), coating type and welding power source.

Welding rod grade refers to the specific classification of welding rod products based on their intended use and performance characteristics.

The grades of welding electrodes are categorized into ten groups, including structural steel electrodes, heat-resistant steel electrodes, stainless steel electrodes, among others.

How to determine whether the welding rod used is reasonable?

To determine the appropriateness of the welding rod selection, it should be evaluated based on its technical performance indicators.

1) Arc stability

The arc is easy to ignite, and the degree of stable combustion (no arc break, drift, magnetic bias blow, etc.) is maintained.

2) Weld formation

Good forming means that the surface is smooth, the ripple is fine and beautiful, and the geometric shape and size of the weld are correct.

3) Adaptability of welding at various positions

All position welding adaptability – all electrodes can be used for flat welding, but some electrodes are not suitable for horizontal welding, vertical welding and overhead welding, so their all position welding performance is poor.

4) Spatter

The metal particles flying out of the droplet or molten pool during welding are called spatter.

Spatter rate = Mass of splash/(Welding rod quality before welding – welding rod quality after welding)*100%

5) Deslagging property

It refers to the difficulty of removing slag shells from the weld surface after welding.

6) Welding rod melting speed

It refers to the quality and length of the melted core in unit time when the electrode is applied; Relatively speaking, the greater the melting speed, the better.

7) Redness of electrode coating

It refers to the phenomenon that when the electrode is used in the second half, the coating becomes red, cracked or falls off due to the high temperature of the coating.

8) Welding fume

a. The Equal Strength Principle states that the tensile strength of the metal deposited from the chosen electrode should be equal to or similar to that of the base metal being welded.

b. The Equal Toughness Principle states that the toughness of the metal deposited from the chosen electrode should be equal to or similar to that of the base metal being welded.

c. The Equal Composition Principle states that the chemical composition of the metal deposited from the chosen electrode should conform to or be close to that of the base metal.

1. Drying of welding rod

The welding rod is prone to absorbing moisture from the atmosphere, which can negatively impact its performance and the quality of the weld.

Therefore, it is important to dry the welding rod (especially alkaline welding rods) prior to use.

Typically, the drying temperature for an acid electrode is between 75-150°C, and it should be kept at this temperature for 1-2 hours.

For an alkaline electrode, the drying temperature should be between 350-400°C, and it should be kept at this temperature for 1-2 hours.

It is important to note that the cumulative drying time of the welding rods should not exceed 3.

2. Storage of welding rods

1) Welding rods should be organized and stored by type, model, and specifications to prevent confusion.

2) The storage area should be well-ventilated and kept dry.

3) Low hydrogen electrodes, which are essential for critical welding structures, should be stored in a dedicated warehouse with a temperature above 5°C and relative humidity no higher than 60%.

4) To protect against moisture damage, the welding rods should be placed on a wooden rack with a minimum distance of 0.3 meters from the ground and walls.

The welding field has seen continuous advancements in technology, leading to an increase in mechanization and automation. This has resulted in higher production efficiency, improved welding quality, and better working conditions.

To further advance the mechanization and automation of welding, welding wires are utilized as the welding material.

What are welding wires referred to as in terms of welding materials?

The wire used as filler metal or for conducting electricity during welding is called welding wire.

a. Classification according to manufacturing method and welding wire shape

It can be divided into solid wire and flux cored wire.

b. Classification according to the applicable welding method

It can be divided into submerged arc welding wire, gas shielded welding wire, electroslag welding wire, surfacing welding wire and gas welding wire.

c. Classification according to the properties of the metal materials to be welded

It can be divided into carbon steel welding wire, low alloy steel welding wire, stainless steel welding wire, nickel base alloy welding wire, cast iron welding wire and special alloy welding wire.

d. Classified by copper plating or not

Copper plated wire and non copper plated wire.

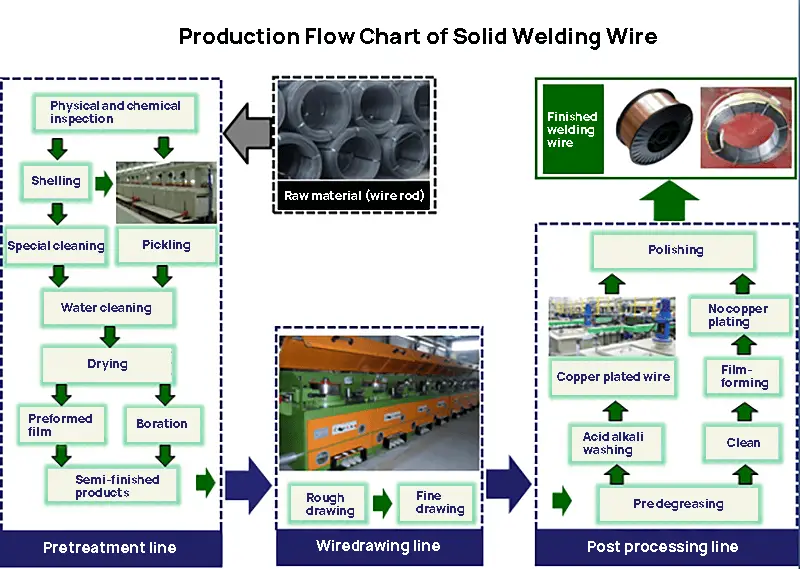

The wire is directly drawn to the target wire diameter. The welding wire without powder is called solid welding wire.

1.1 Production process of solid welding wire

1.2 Model of solid welding wire

1.3 Brand of solid welding wire

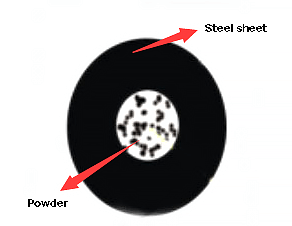

2. What kind of welding wire is flux cored?

The thin steel strip is rolled into different sectional shapes, filled with powder, and then drawn into a kind of welding wire called flux cored wire.

The filled powder is called the core, and its effect is similar to that of the electrode coating.

2.1 Model of flux cored wire

2.2 Brand of flux cored wire

According to the wire structure, flux cored wire can be divided into: seam and seamless.

Seamless flux cored wire can be copper plated, with good performance and low cost, which has become the development direction in the future.

2.3 Production process of flux cored wire

For the production of seam flux cored wire, the “steel strip method” is commonly used;

For the production of seamless flux cored wire, the “steel pipe method” is commonly used.

a. Steel strip method

b. Steel tube method

Advantages:

Small spatter, fast deposition speed, and high production efficiency.

Welding of various steels with strong adaptability.

Good process performance and a beautiful weld formation.

A large welding current can be used for welding in all positions.

Disadvantages:

The manufacturing process of welding wire is intricate and expensive.

The surface of the welding wire is prone to rusting and the powder is susceptible to moisture absorption.

Wire feeding during the welding process is more challenging compared to using solid wire, resulting in a large amount of smoke.

This picture depicts the process of submerged arc welding.

Do you notice the “sand” on top?

It is an essential welding material, known as the flux, in the submerged arc welding process.

Flux is a granular material that melts to form slag and gas during welding and plays a protective and metallurgical role in molten metal.

Effect:

1) Protect the molten pool metal;

2) Add alloy elements to the molten pool.

(1) Classification by Use

It can be categorized into three types: Submerged Arc Welding Flux, Electroslag Welding Flux, and Surfacing Flux.

(2) Classification by Manufacturing Method

It can be divided into two categories: Smelting Flux and Non-Smelting Flux.

(3) Classification by Slag Alkalinity

It can be classified into three categories: Acid Flux, Neutral Flux, and Basic Flux.

a. Melting flux

The flux is created by melting various ingredients in a precise proportion in a furnace. The mixture is then granulated, dried, and screened while being cooled with water.

Characteristic:

1) It is not difficult to absorb moisture and typically does not require drying prior to use.

2) The flux that has not melted can be utilized again.

3) After being melted, it is cooled quickly, often taking the form of glass.

4) Only a limited amount of alloy elements can be added to the flux in the molten pool, as a large quantity cannot be transferred.

Melting flux

Main components:

b. Unmelted flux

The non-melting flux is obtained by mixing various powders according to a specific formula, adding a binder to form particles of a specific size, and then baking or sintering.

Bonding flux is a type of flux that is baked at low temperatures (below 400 ℃).

Sintered flux, on the other hand, is produced by sintering the flux at high temperatures (700 to 1000 ℃).

Characteristic:

1) The moisture absorption is relatively high, and it must be re-dried before use.

2) Easy to manufacture and highly applicable.

Sintered flux

Essential component(SJ101):SJ102

Classification according to slag alkalinity:

(1) Acid flux (alkalinity B<1.0)

The slag is primarily composed of acid oxides and has excellent welding performance, resulting in a visually appealing weld formation. However, the weld metal has a high oxygen content, which results in low low-temperature impact toughness.

(2) Neutral flux (alkalinity 1.0 ~ 1.5)

The composition of the deposited metal is similar to that of the welding wire, with a reduced oxygen content in the weld metal.

(3) Alkaline flux (alkalinity B>1.5)

The primary components of slag are alkaline oxides and calcium fluoride. The weld metal is characterized by a low oxygen content, high impact toughness, and good tensile properties.

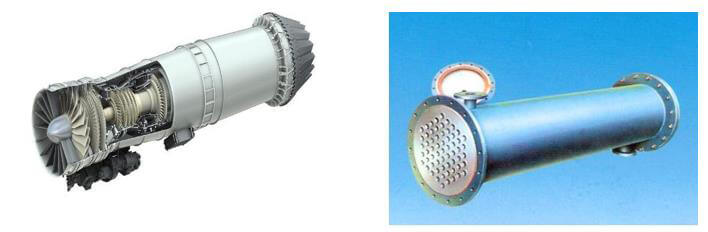

In modern, cutting-edge scientific and technological projects, such as aircraft plate fin radiators, rocket shells, engine nozzles, and others, they all require high precision and sharpness and cannot tolerate any defects. Almost all products must be of impeccable quality.

Brazing technology is widely used in these fields due to its advantages of low thermal impact, high precision, wide applicability, and high welding efficiency. It allows for the connection of multiple, complex, high-precision parts.

The brazing filler metal plays a crucial role in the brazing process.

In order to realize the combination of two materials (or parts), the filler added in or beside the gap is called filler metal.

(1) A melting point that is appropriate (several tens of degrees lower than the base metal);

(2) Excellent wettability;

(3) Completely dissolved and integrated with the base metal;

(4) A uniform and stable composition;

(5) It is cost-effective and safe (containing fewer precious metals and toxic metals).

1) Classification by melting point

“Soft solder” (also known as “fusible solder”) refers to solders with melting points lower than 450°C, including tin-lead solder, cadmium-silver solder, and lead-silver solder, among others.

“Brazing filler metal” (also referred to as “refractory filler metal”) refers to brazing fillers with melting points higher than 450°C, including aluminum-based, copper-based, silver-based, and nickel-based brazing fillers, among others.

2) Classification by main chemical components

According to the main metal elements of solder, it is called × base solder, such as brazing base solder, zinc base solder, etc.

3) Sort by shape

It can be divided into wire, rod, sheet, foil, powder or solder with special shape (such as annular solder or paste solder).

(1) Soft solder

It is primarily used for welding workpieces with low stress and low operating temperatures, such as connecting various electrical wires and soldering instruments, components of instruments, and other electronic circuits.

(2) Brazing filler metal

It is mainly used to weld workpieces with large force and high working temperature, such as bicycle frame, carbide cutter, drilling bit and other mechanical parts.

In order to obtain a better welding joint, it is necessary to reasonably match the brazing flux according to the different brazing filler metals to jointly use as the welding materials in the brazing process.

The flux used in brazing is called brazing flux, including paste, powder, etc.

1) Remove the oxide layers from the surface of the solder and base metal.

2) Enhance the ability of the liquid solder to wet the weldments.

3) Prevent the weldment and liquid solder from being oxidized during the brazing process.

1) Ensure that there is enough capability to eliminate oxides from the surface of the base metal and filler metal.

2) The brazing flux’s melting point and minimum active temperature should be lower than the melting point of the brazing filler metal.

3) Ensure adequate wetting ability at the brazing temperature.

4) The volatiles in the flux should be non-toxic.

5) The flux and its residue should have minimal corrosion to the solder and base metal and should be easily removable.

1) Soft Soldering Flux

The soldering flux used for brazing at temperatures below 450 ℃ can be divided into two types: inorganic and organic.

a. Inorganic Soft Solder (Corrosive Soft Solder) – It is composed of inorganic salts and acids and has strong chemical activity and thermal stability. This type of solder promotes the wetting of liquid solder to the base metal effectively, but its residue has a strong corrosive effect.

b. Organic Soldering Flux (Non-Corrosive Soldering Flux) – Its chemical activity is relatively weak and does not corrode the base metal. Examples of non-corrosive soldering fluxes include rosin, amine, and organic halides.

2) Brazing Flux

The flux used for brazing at temperatures above 450 ℃ has a high viscosity and requires high temperature activation.

It must be used at temperatures above 800 ℃, and its residue is difficult to remove.

Common brazing fluxes include borax, boric acid, and their mixtures. Adding fluoride and chloride of alkali and alkaline earth metals to borides can improve the wettability of borax and boric acid brazing fluxes, enhance oxide removal, and lower the melting and activation temperature of the brazing fluxes.

Welding gas primarily refers to the protective gas utilized in gas shielded welding processes, such as CO2 gas shielded welding and inert gas shielded welding, as well as the gas used in gas welding and cutting.

When welding, the shielding gas serves not only as a protective medium for the welding area, but also as the gas medium that generates the arc.

Gas welding and cutting are typically performed using a high-temperature flame generated from the combustion of gas, which provides a concentrated source of heat.

| Emotional gas | Molecular gas | Compound gas |

| Argon, ammonia | Oxygen, nitrogen, hydrogen | carbon dioxide |

That is, combustion supporting gas (O2) and combustible gas (acetylene C2H2).

| Gas | Symbol | Main properties | Application in welding |

| carbon dioxide | CO2 | It has stable chemical property, does not burn or support combustion, can be decomposed into C0 and 0 at high temperature, and has certain oxidizability to metals. It can liquefy liquid CO2, absorb a lot of heat when evaporating, and solidify into solid CO2, commonly known as dry ice | Welding wire can be used as shielding gas during welding, such as CO2 gas shielded welding and C02+O2, C02+A and other mixed gas shielded welding |

| argon | Ar | Emotional gas, not active in chemical property, does not react with other elements at room temperature and high temperature | As a protective gas for mechanical protection during arc welding, plasma welding and cutting |

| oxygen | O2 | Colorless gas, combustion supporting, very active under high temperature, directly combined with various elements. During welding, oxygen will oxidize metal elements when it enters the molten pool, which will play a harmful role | It can obtain extremely high temperature when mixed with combustible gas for welding and cutting, such as oxygen acetylene flame and hydrogen oxygen flame. Mix with argon, carbon dioxide, etc. in proportion, and conduct mixed gas shielded welding |

| B fast | CH2 | Commonly known as calcium carbide gas, it is less soluble in water, soluble in alcohol, and largely soluble in acetone. It mixes with air and oxygen to form an explosive gas mixture. It burns in oxygen and emits high temperature and strong light | For oxyacetylene flame welding and cutting |

| hydrogen | H2 | It can burn, is not active at normal temperature, and is very active at high temperature. It can be used as a reducing agent for metal ores and metal oxides. It can be melted in liquid metal during welding and precipitated when cooling, which is easy to form pores | When welding, it can be used as a reducing shielding gas, mixed with oxygen for combustion, and can be used as a heat source for gas welding |

| nitrogen | N2 | The chemical property is not active, and it can be directly combined with hydrogen and oxygen at high temperature. It is harmful to enter the molten pool during welding. It does not react with copper basically and can be used as protective gas | During nitrogen arc welding, nitrogen is used as the shielding gas to weld copper and stainless steel. Nitrogen is also commonly used in plasma arc cutting as the outer protective gas |

| Gas | component | Arc column potential gradient | Arc stability | Metal transition characteristics | Chemical properties | Weld penetration shape | Heating characteristics |

| CO2 | 99.9% purity | high | satisfied | Satisfied, but some splashes | Strong oxidation | Flat shape with large penetration | – |

| Ar | Purity 99.995% | low | good | satisfied | – | Mushroom shape | – |

| He | 99.99% purity | high | satisfied | satisfied | – | Flat | The heat input of butt weldment is higher than that of pure Ar |

| N2 | 99.9% purity | high | difference | difference | Produce porosity and nitride in steel | Flat | – |

1)Ar + He

It can enhance weld penetration, decrease porosity, and enhance production efficiency.

It can be used on copper, aluminum, and their alloys, as well as titanium, zirconium, and other metals.

2)Ar + H2

The addition of hydrogen can raise the arc temperature, increase the heat input to the base metal, and reduce the formation of CO porosity.

The blended gas is a reducing agent and is ideal for welding nickel and its alloys, as well as stainless steel pipes.

3)Ar + N2

To enhance the arc temperature, you should add N2. A slight addition of N2 can enhance the arc rigidity and enhance the weld formation.

This technique is suitable for welding non-ferrous metals, such as copper and aluminum.

4)Ar + O2

The oxygen content in Ar+O2 (low content) is in the range of 1-5%, which enhances the wettability of the solution, minimizes porosity, and stabilizes the arc. This method is suitable for welding stainless steel, including low carbon steel and low alloy steel.

Ar+O2 (high content) has an oxygen content of approximately 20%, which increases production efficiency, reduces porosity, and enhances the impact toughness of welds. This method is appropriate for welding carbon steel and low alloy structural steel.

5)Ar + CO2

Stable arc, minimal spatter, simple to attain axial spray transfer, optimal weld formation, and a broad range of applications (suitable for both spray transfer and short circuit transfer).

6)Ar + CO2 + O2

It has been confirmed that the optimal gas mixture for welding low carbon and low alloy steel is 80% Argon, 15% Carbon Dioxide, and 5% Oxygen. This mixture provides excellent results in terms of weld formation, joint quality, metal transfer, and arc stability, and is highly satisfactory.

7)CO2 + O2

High deposition rate, deep penetration, low hydrogen content in the weld metal, strong welding with high current specifications, stable arc, and minimal spatter.

A groove created along the toe or root of a weld.

1) Excessive welding current;

2) The welding arc is too long;

3) The electrode angle is incorrect.

Incomplete penetration of joint root during welding.

1) Incorrect groove size;

2) Improper selection of welding process parameters;

3) The electrode deviates from the groove center or the angle is incorrect.

Incomplete fusion and bonding between weld metal and base metal or weld bead metal.

1) The welding current is too small or the welding speed is too high;

2) Unqualified cleaning before welding;

3) The electrode deviates from the weld center.

A depression formed at the end of a weld or at a joint.

During welding, molten metal flows out from the back of the groove to form perforation.

A metal nodule formed when molten metal flows to the unmelted base metal outside the weld.

Slag or non-metallic impurities left in the weld after welding.

A hole formed by gas remaining in the weld after welding.

Gas source forming pore:

1) Outside air;

2) Moisture;

3) Oil contamination and impurities.

(1) According to welding position

(2) According to the crack direction

① The longitudinal crack is parallel to the weld

② Transverse crack perpendicular to weld

(3) According to the conditions of crack generation

① Hot crack Crack near the solidus temperature of weld and heat affected zone

② A crack cooled below the martensitic transformation temperature

③ Reheat crack

④ Ladder shaped cracks along the rolling direction of plate due to lamellar tearing

In CO2 welding, most of the melted metal from the welding wire is transferred to the weld pool, but some of it escapes and forms splatter. When using thick welding wire for CO2 gas shielded welding with large parameters, the splatter can become particularly severe, with a rate as high as 20%.

This results in an inability to perform normal welding. The splatter is harmful, as it decreases welding efficiency, impacts the quality of the weld, and creates poor working conditions.

Splash hazard

The metal spatter loss in CO2 gas shielded welding can account for anywhere from 10% to 30-40% of the melted metal from the welding wire. The ideal loss is controlled to 2-4%.

This loss has several negative impacts:

Preventing and reducing metal spatter is a crucial consideration in CO2 gas shielded welding.

Measures to reduce splash

(1) Correct selection of process parameters

There is a correlation between the spatter rate and welding current for each diameter of welding wire in CO2 arc welding. In the low current area (short circuit transition area), the spatter rate is low. When the current enters the high current area (fine particle transition area), the spatter rate decreases again. However, the spatter rate is highest in the middle area.

The spatter rate is low when the welding current is less than 150A or more than 300A, and it is high between these two values. To minimize the spatter rate, it is best to avoid selecting welding currents in this high spatter rate area.

Once the welding current has been determined, the appropriate voltage should be chosen to ensure the lowest possible spatter rate.

The spatter amount is at its minimum when the welding gun is held vertically. As the inclination angle of the gun increases, the spatter rate also increases. It is recommended not to tilt the welding gun forward or backward by more than 20 degrees.

The spatter rate is also affected by the extension length of the welding wire. It is best to keep the length of the welding wire as short as possible to minimize spatter.

(2) Select appropriate welding wire material and shielding gas composition.

For example:

The experience shows that when the carbon content in the welding wire is reduced to 0.04%, spatter can be significantly reduced.

The flux core in tubular welding wire includes deoxidizers and arc stabilizers, providing gas slag joint protection, making the welding process more stable, and reducing spatter significantly. The metal spatter rate of flux cored wire is approximately one-third of that of solid wire.

(3) CO2 mixture is used as shielding gas during long arc welding.

Although the spatter rate can be reduced through the proper selection of specification parameters and the use of the submerged arc method, the amount of spatter produced is still significant.

Incorporating a certain amount of Argon (Ar) gas into Carbon Dioxide (CO2) gas is the most effective method to reduce metal spatter that is caused by excessive welding of particles.

The physical and chemical properties of pure CO2 gas are altered when Argon is added to the mix.

As the ratio of Argon gas increases, the amount of spatter decreases gradually.

The CO2+Ar mixed gas not only reduces spatter but also improves weld formation, influencing weld penetration, height, and reinforcement.

When the Argon content reaches 60%, the size of the transfer droplets can be noticeably reduced and even spray transfer can be achieved, thus improving droplet transfer characteristics and reducing metal splash.

1. Weld scale

Repair method

Weld surface after descaling

2. Air hole

Repair method: Grind and remove the weld and re weld.

3. Crater needle shaped air hole

4. Air hole (sand hole)

5. Shrinkage cavity

6. End crack/weld crack

7. Appearance of bad welds

8. Overlap and flash

9. Undercut

10. Uneven weld

11. Poor appearance

The weld symbol is made up of a basic symbol and a leader line, and if necessary, additional symbols, supplementary symbols, and symbols indicating the size of the weld.

The basic symbol represents the cross-sectional shape of the weld and is similar to the symbol for the cross-sectional shape of the weld found in Table 4-2.

Auxiliary symbols are symbols that indicate the shape characteristics of the weld’s surface. These symbols can be omitted if specifying the surface shape of the weld is not necessary.

Supplementary symbols are used to complement the symbols that represent certain characteristics of the weld surface. The methods of representing these symbols are shown in Table 4-3.

If the size of the weld needs to be specified during design or production, it is indicated by the weld size symbol, as illustrated in Table 4-4.

Table 4-2 Basic Symbols of Weld Forms

| Serial No | Weld name | Weld type | Basic symbols |

| 1 | I-shaped weld |  | |

| 2 | V-shaped weld |  | |

| 3 | Blunt V weld |  | |

| 4 | Unilateral V-shaped weld |  | |

| 5 | Single V-shaped weld with blunt edge |  | |

| 6 | U-shaped weld |  | |

| 7 | Unilateral U-shaped weld |  | |

| 8 | Flare weld |  | |

| 9 | Fillet weld |  | |

| 10 | Plug weld |  | |

| 11 | Spot weld |  | |

| 12 | Seam weld |  | |

| 13 | Back bead |  |

Table 4-3 Auxiliary Symbols and Supplementary Symbols of Welds

| Serial No | Name | Type | Auxiliary symbol | Explain |

| 1 | Plane symbol | Indicates that the weld surface is flush | ||

| 2 | Depression symbol |  | Denotes weld surface depression | |

| 3 | Raised symbol |  | Indicating weld surface bulge |

| Serial No | Name | Type | Supplementary symbol | Explain |

| 1 | Symbol with backing plate | Indicates that there is a backing plate at the bottom of the weld | ||

| 2 | Three side weld symbol |  | It is required that the opening direction of the three side weld symbol is basically consistent with the actual direction of the three side weld | |

| 3 | Peripheral weld symbol |  | Indicates welding around the workpiece | |

| 4 | Site Symbols |  | Indicates welding at site or construction site |

Table 4-4 Size Symbols of Welds

| Symbol | Name | Sketch Map |

| δ | Sheet thickness | |

| α | Groove angle |  |

| b | Butt clearance |  |

| p | Height of blunt edge |  |

| c | Weld width |  |

| K | Fillet size |  |

| d | Nugget diameter |  |

| S | Effective thickness of weld |  |

| N | Number of identical welds symbol |  |

| K | Fillet size |  |

| R | Root radius |  |

| l | Weld length |  |

| n | Number of weld segments | |

| H | Groove depth |  |

| h | Weld reinforcement |  |

| β | Groove face angle |

(1) The leader line is made up of an arrow line with an arrowhead, and two reference lines (one is a thin solid line, and the other is a dotted line).

(2) The dotted line can be located either above or below the thin solid line.

The datum line is usually parallel to the long side of the title block, but it can also be perpendicular to the long side of the title block if required.

The arrow line is drawn using a thin solid line, and the arrow points to the relevant weld seam. If necessary, the arrow line can be bent once.

If it is necessary to describe the welding method, a tail symbol can be added at the end of the reference line.

(1) The dimensions across the cross-section of the weld are marked on the left side of the basic symbol.

(2) The dimensions along the length of the weld are marked on the right side of the basic symbol.

(3) The groove angle (α), groove face angle (β), and root gap (b) are marked either above or below the basic symbol.

(4) The same weld quantity and welding method code are indicated at the tail.

(5) If there is a large amount of dimension data to be marked and it becomes difficult to distinguish, corresponding dimension symbols can be added in front of the data to help clarify the information.

Table 12-1 Weld Symbols and Marking Methods

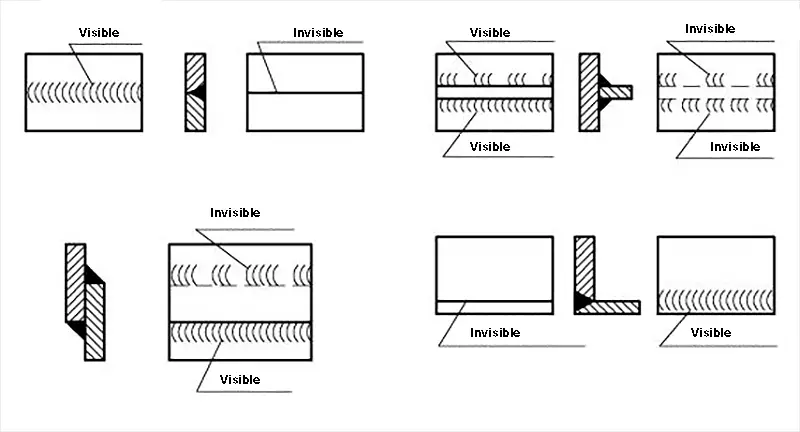

The common welded joints are butt joint, T-joint, corner joint and lap joint, as shown in the figure.

The selection of welded joints is primarily based on the structure of the welding, the thickness of the weldment, the strength requirements of the weld, and the conditions under which the construction is taking place.

Specified drawing method of weld

The line formed after welding the workpieces together is referred to as the weld seam.

If a simple representation of the weld is needed in a drawing, it can be depicted using a view, section view, or axonometric diagram.

The specific method of representing the weld in a drawing is shown in the figure.

Structural welding always results in welding deformation and stress.

During the welding process, the deformation and internal stress generated in the weldment that change over time are referred to as transient deformation and transient welding stress, respectively.

The deformation and stress that remain in the weldment after the temperature has cooled to room temperature after welding are known as residual welding deformation and residual welding stress, respectively.

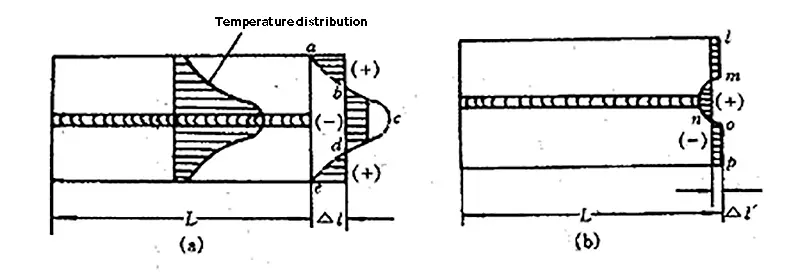

The root cause of welding stress and deformation is the uneven heating and cooling of the weld zone.

During the welding process, the weldment is heated locally, causing deformation to occur due to the metal’s characteristic of expanding and contracting.

However, the steel plate is a solid piece, and this expansion cannot occur freely.

The end of the steel plate can only expand evenly by an amount of Δι.

(a) During welding;

(b) After welding.

During cooling, the metal near the weld has undergone permanent compressive plastic deformation during welding and is also restricted by the metal on both sides.

In order to maintain overall consistency, Δι‘ is reduced evenly, which generates a certain amount of elastic tension in the weld area and a certain amount of elastic compression in the metal on both sides.

As a result, there is tensile stress in the weld zone and the surrounding metal, and there is compressive stress in the metal on both sides.

The stress in the member is in a state of balance. It can be observed that after butt welding a flat plate, the length of Δι‘ is shorter than it was before welding.

At the same time, tensile stress is generated in the weld zone and the metal on both sides, far from the weld, experiences compression stress.

In other words, the welding stress and deformation are maintained at room temperature and are known as residual welding stress and deformation.

Welding stress can be divided into four categories: thermal stress, restraint stress, phase change stress, and residual welding stress. The residual welding stress is often very high.

In structures with thick welding, the residual welding stress can usually reach the yield strength of the material.

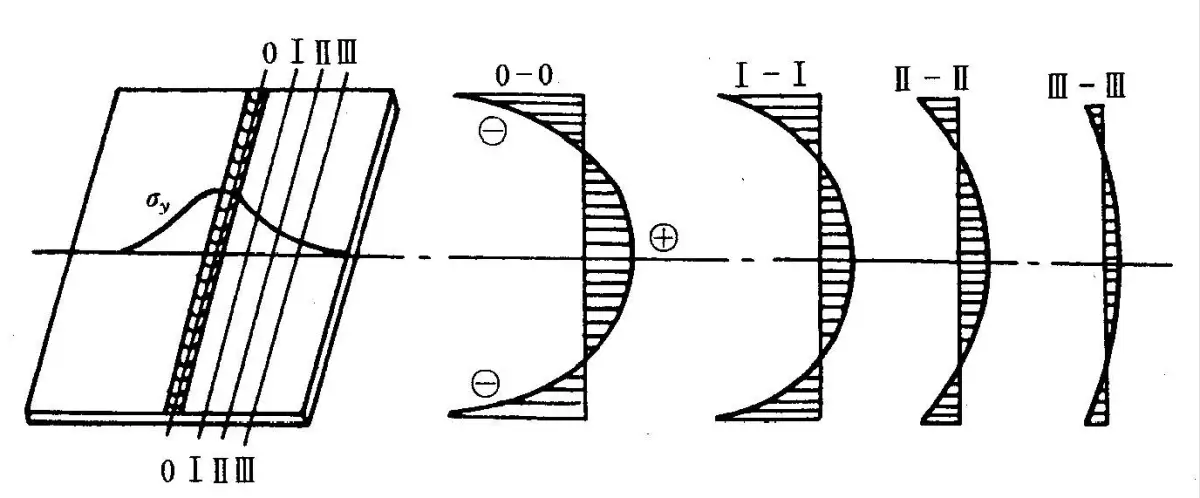

(1) Longitudinal stress: Stress along the length of the weld.

(2) Transverse stress: Stress perpendicular to the length of the weld and parallel to the surface of the component.

(3) Stress in the thickness direction: Stress perpendicular to the length of the weld and the surface of the component.

(1) Longitudinal stress of weld σ x

The stress along the longitudinal direction of the weld is referred to as longitudinal stress (σ x).

The stress perpendicular to the longitudinal direction of the weld is referred to as transverse stress (σ y).

In the zone of compressive plastic deformation near the weld, the longitudinal stress (σ x) is tensile stress, which can typically reach the yield strength of the material.

(2) Transverse stress of weld

The figure illustrates the distribution of transverse stress (σy) in a plate weld of a certain length.

σy is tensile stress in the weld and the zone of compressive plastic deformation near the weld, while the two ends experience compressive stress.

The further away from the center of the weld, the quicker σy decreases.

In addition to the longitudinal and transverse stresses, there are also stresses along the thickness direction in thick plate welded structures.

The stress distribution in the three directions is highly uneven in the thickness direction.

Thick plate electroslag welding results in three axial tensile stresses at the center of the weld, which increase with the increase in plate thickness, but the surface experiences compressive stress.

(1) Impact on the Strength and Stability of Compressive Parts

When the component is under tensile load, the residual welding stress will be added to the load stress, affecting the component’s strength.

(2) Influence on Brittle Fracture of Components

The increase in the nominal stress of the component, combined with the decrease in material toughness in the welding joint area and the presence of welding defects, will increase the likelihood of brittle fracture under low external loads.

(3) Effect on Fatigue Strength

The residual tensile stress in the weld zone can raise the average tensile stress value of the structure and reduce its fatigue life.

(4) Impact on Machining Accuracy and Dimensional Stability of Weldments

(5) Effect on Crack Propagation

When evaluating the crack state of the welding zone, the residual welding stress must be taken into consideration.

When calculating the stress intensity factor (KI) that drives crack growth, the residual stress (σr) is taken into account by using the equivalent tensile stress (σ3), which represents the contribution of residual stress to crack growth:

σ3 = αrσr

Where σr is related to the type of crack (through crack, buried crack, surface crack) and the direction of the crack (cracks parallel to the fusion line, cracks perpendicular to the fusion line, and fillet weld cracks).

Reducing Welding Residual Stress through Design and Welding Process

(1) The key to reducing welding stress in design is to properly arrange the welds to avoid stress overlap and reduce peak stress.

① Minimize the number of welds and reduce the size and length of the welds.

② The welds should be spaced out sufficiently and avoid crossing as much as possible to prevent complex three-dimensional stress.

③ Welds should not be located in areas with high stress and abrupt changes in cross-section to avoid stress concentration.

④ The more flexible table type joint should be used, and flanging should replace the insertion tube.

(2) Techniques for Reducing Welding Stress in the Process

① Adopt a reasonable welding sequence and direction, and perform most welds with less rigidity.

② Minimize the temperature difference between the welding area and the entire structure to reduce internal welding stress. Use overall preheating and low linear energy.

③ Utilize hammer welding to reduce welding stress and deformation.

④ Decrease the hydrogen content and eliminate hydrogen.

(3) The method for eliminating residual stress primarily involves eliminating residual stress after welding. For boilers and pressure vessels with a pressure component thickness exceeding a certain size, post-welding heat treatment is required to eliminate internal stress.

Generally, welding causes deformation of the workpiece. If the deformation exceeds the acceptable limit, it will affect functionality.

The main cause of deformation is uneven heating and cooling of the weldment during welding.

During welding, the weldment is only heated in local areas, but the metal in the heated area cannot expand freely due to the metal with lower temperature around it.

When cooling, it cannot shrink freely due to containment by surrounding metal.

As a result, this part of the heated metal experiences tensile stress, while other parts of the metal experience compressive stress in balance with it.

When these stresses exceed the yield limit of the metal, welding deformation occurs.

Cracks appear when the strength limit of the metal is exceeded.

1. Welding deformation forms

The forms of welding deformation can be varied. The most common forms are five basic forms, or combinations of these forms.

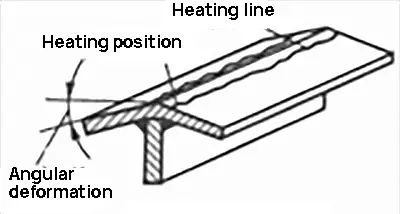

Figure (a) illustrates the longitudinal and transverse shrinkage deformation in a flat plate after butt welding;

Figure (b) illustrates the angular deformation in a flat plate after docking;

Figure (c) illustrates the bending deformation caused by the deviation of the welding arrangement in a cylinder from the centroidal axis of the weldment;

Figure (d) illustrates the wavy deformation in a thin-walled weldment after welding.

Additionally, beam-column structures are susceptible to distortion during welding.

Shrinkage deformation and bending deformation are forms of overall deformation, while the other forms are considered local deformation.

2. Influencing factors of welding deformation

(1) The Effect of Weld Position on Welding Deformation

When the welds are symmetrically arranged in the structure, only longitudinal and transverse shortening occurs. However, if the welds are arranged asymmetrically in the structure, bending deformation will occur. Angular deformation will occur when the center of gravity of the weld section deviates from the center of gravity of the joint section.

(2) Influence of Structural Rigidity

Under the same force, structures with large rigidity have less deformation, while structures with low rigidity have more deformation. Welding deformation is always carried out in the direction with the least constraint of structural or weldment rigidity.

(3) Effect of Assembly and Welding Sequence

The rigidity constraint when welding a strip weld depends on the assembly and welding procedure. For structures with symmetrical sections and welds, a method of first assembling into a whole can be used. For complex welding structures, due to the multiple welds, the deformation caused by each weld affects the other welds, making it difficult to control. Thus, a procedure of partial assembly, welding, reassembly, and re-welding must be adopted to control the overall welding deformation.

(4) Other Influential Factors

Deformation is also closely related to groove type, assembly clearance, welding specifications, and welding method.

3. Methods for controlling welding deformation

To control and minimize welding deformation, it is essential to adopt appropriate design schemes and process measures.

(1) Reduce the number, length, and size of welds as much as possible while ensuring reasonable design for bearing capacity.

Arrange the position of the welds in a reasonable manner, such that all welds in the structure are symmetrical to, or as close as possible to, the neutral axis of the section. This will help to reduce the deformation of the weldment.

(2) Necessary Process Measures:

① Reserve Shrinkage Allowance:

When preparing the workpiece, add a suitable shrinkage allowance.

Typically, the longitudinal shrinkage of the weld is calculated based on the length of the weld and depends on factors such as groove, joint type, and plate thickness.

② Reverse Deformation Method:

Employ experience or calculation methods to determine the reverse deformation method.

Before welding, it’s crucial to assess the size and direction of potential deformation of the workpiece. To prevent residual deformation, place the weldment in the opposite direction of the deformation or apply artificial deformation beforehand during assembly. Proper control will help ensure that the workpiece attains the correct shape.

③ Select Appropriate Welding Methods and Specifications:

Utilize energy-concentrated heat sources and fast welding methods to reduce deformation.

④ Optimal Assembly and Welding Sequence:

Divide the large structure into smaller parts, assemble and weld each part separately, and then join the parts together into a complete whole.

⑤ Sturdy Fixation:

Fix and clamp the structure before welding to reduce deformation through external constraints. However, rigid clamping can prevent the free shrinkage of the weldment, leading to high internal stress within the component.

Therefore, it is crucial to carefully select the weldment material and structure.

⑥ Use reasonable welding sequence

4. Correction of welding deformation