Introduction to welding

Welding typically refers to the process of joining two metal objects into a single integral form by heating or applying pressure.

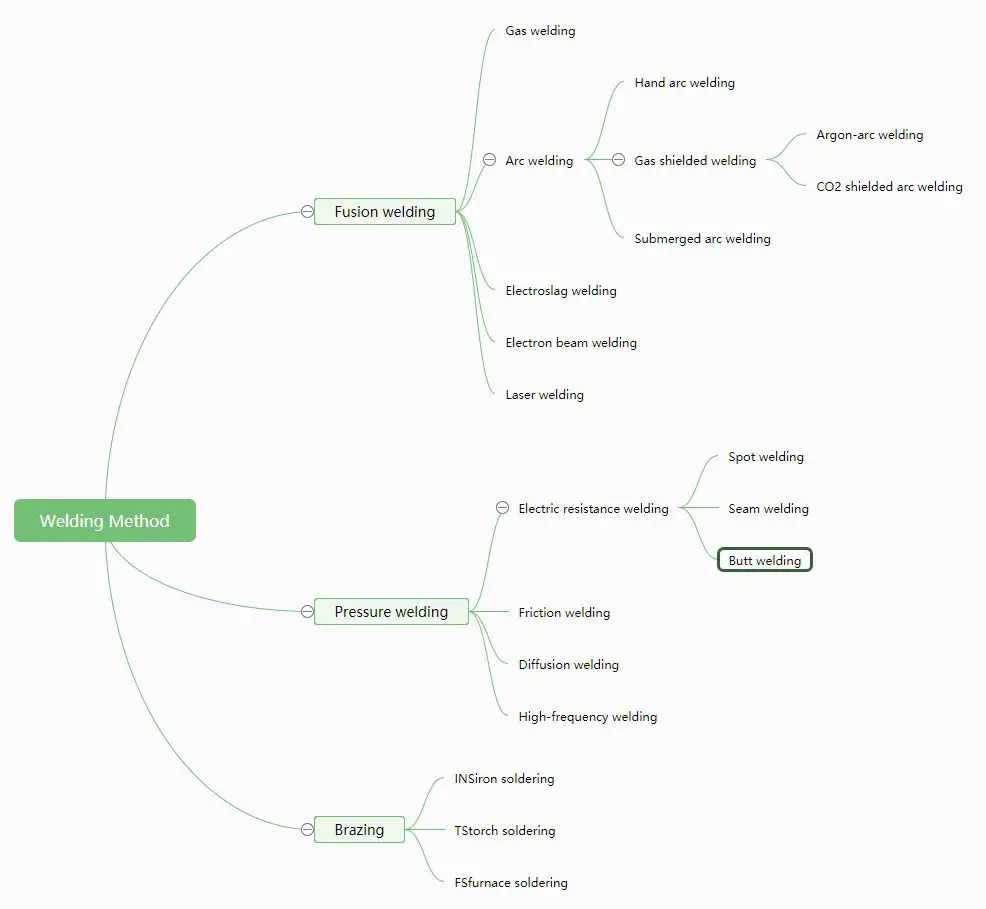

Classification: Welding methods can be classified into three categories based on the degree of heating and the process characteristics involved in the welding process.

(1) Fusion Welding

In fusion welding, the workpiece is heated to a molten state and a molten pool is formed, usually filled with filler metal. After cooling and crystallization, the weld seam is formed and the two parts are integrated into one piece. Some common fusion welding methods include gas welding, arc welding, electro-slag welding, plasma arc welding, electron beam welding, and laser welding.

(2) Pressure Welding

Pressure welding requires pressure, with or without heating, during the welding process. Common pressure welding methods include resistance welding, friction welding, cold pressure welding, diffusion welding, and explosive welding.

(3) Brazing

Brazing is a process where a filler metal with a lower melting point than the base metal is used to fill the joint gap and connect with the base metal through diffusion. The base metal does not melt during brazing and there is generally no plastic deformation.

Characteristics of Welding Production:

(1) Welding saves metal materials and results in a light structure.

(2) It allows for the reduction of large parts into smaller ones and the manufacturing of heavy and complex machine parts. It also simplifies casting, forging, and cutting processes, leading to the best technical and economic results.

(3) Welded joints have good mechanical properties and tightness.

(4) Welding allows for the full utilization of material properties to manufacture bimetallic structures.

Introduction of various welding technologies

01 Electric Arc Welding

Electric Arc:

It is a strong and persistent discharge of gas that occurs between two electrodes with a certain voltage. The gas between the electrodes must be in an ionized state for the electric arc to occur.

To ignite the arc, two electrodes are connected to a power source (one being the workpiece and the other being the filler metal wire or electrode). The arc is formed when a brief contact and rapid separation cause a short circuit between the two electrodes. This is referred to as a contact arc.

Once the arc is formed, it will continue to burn as long as there is a potential difference between the electrodes maintained by the power source.

Characteristics of Electric Arc:

The electric arc has several unique features, including low voltage, high current, high temperature, high energy density, and good mobility.

To maintain stable combustion, the voltage must be between 20-30V. The current in the arc can range from dozens to thousands of amps, depending on the welding requirements of the workpiece. The temperature of the arc can reach over 5000K, making it capable of melting any type of metal.

The electric arc consists of three parts: the cathode area, the anode area, and the arc column.

Arc Welding Power Source:

The power source used in arc welding is known as the arc welding power source, which can be divided into four types: AC arc welding power source, DC arc welding power source, pulse arc welding power supply, and inverter arc welding power source.

Direct Current (DC) Connection:

A DC welding machine is used when the workpiece is connected to the anode and the electrode is connected to the cathode. This is referred to as a direct current connection. In this configuration, the workpiece is heated and is ideal for welding thick workpieces.

Reverse Direct Current (DC) Connection:

When the workpiece is connected to the cathode and the electrode is connected to the anode, it is called a reverse DC connection. In this configuration, the workpiece is hot and small, making it suitable for welding thin and small workpieces.

Alternating Current (AC) Connection:

When welding with an AC welding machine, there is no positive or reverse connection problem due to the alternating nature of the current polarity.

Welding Metallurgical Process:

In the process of arc welding, liquid metal, slag, and gas interact with each other, which is the process of metal remelting. However, due to the unique nature of welding conditions, the welding chemical metallurgical process is different from the general smelting process.

First, the temperature in welding metallurgy is high, the phase boundaries are large, and the reaction speed is fast. When air enters the arc, the liquid metal reacts with strong oxidation and nitridation, leading to significant vaporization of the metal. At high temperatures, water, oil, rust, and other impurities in the air and welding materials decompose into hydrogen atoms, which can dissolve in liquid metal, reducing the plasticity and toughness of the joints (hydrogen embrittlement) and leading to cracks.

Second, the welding pool is small and cools quickly, making it difficult for various metallurgical reactions to reach equilibrium. The chemical composition of the weld is not uniform, and gases and oxides in the molten pool are slow to rise to the surface, leading to defects such as porosity, slag, and even cracks.

To address these issues, the following measures are typically taken during the arc welding process:

(1) Mechanical protection of the molten metal is provided to separate it from the air. There are three types of protection: gas protection, slag protection, and gas-slag joint protection.

(2) Metallurgical treatment of the welding pool is performed by adding a certain amount of deoxidizers (mainly ferromanganese and ferrosilicon) and alloy elements to the welding material (electrode coating, welding wire, and flux). This eliminates FeO in the molten pool during the welding process and compensates for the damage caused by the alloy elements.

Common shielded metal arc welding (SMAW) method:

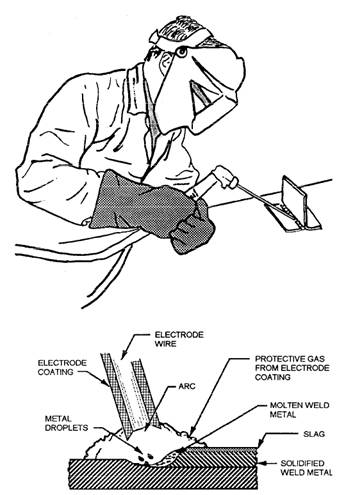

1 Manual metal-arc welding

Manual metal-arc welding is one of the earliest and most widely utilized welding techniques. It uses a coated filler rod as the electrode and added metal, and an arc is created between the electrode’s end and the welding surface.

The coating protects the arc by producing gas, while the deposited molten slag prevents interaction between the molten metal and the surrounding gas. Slag plays a crucial role in producing physical and chemical reactions with the molten metal, as well as adding alloy elements to improve the energy of the weld metal.

The equipment used in manual metal arc welding is simple, lightweight, and versatile. It is ideal for welding short joints in maintenance and assembly work, particularly in hard-to-reach areas.

This welding technique can be applied to a wide range of materials, including industrial carbon steel, stainless steel, cast iron, copper, aluminum, nickel, and alloys.

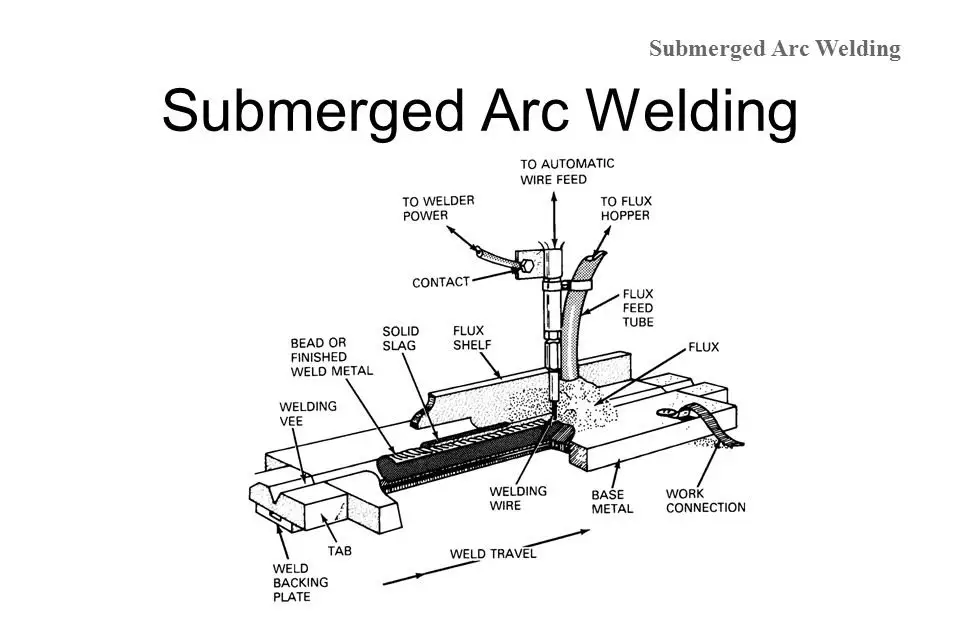

2 Submerged arc welding

The Submerged Arc Welding (SAW) process is similar to Gas Metal Arc Welding (GMAW), but the arc is struck under a layer of granular flux. The filler metal used in SAW is a continuously fed wire electrode, similar to GMAW and Flux Cored Arc Welding (FCAW). However, SAW can achieve higher deposition rates by using larger diameter electrodes (up to 1/4 inch) and higher currents (in amperes).

The process is highly mechanized, allowing for several variations, such as the use of multiple torches and narrow gap welding. SAW is a fusion electrode welding method that uses granular flux as a protective medium and the arc is hidden under the flux layer.

The welding process in SAW consists of three steps:

- Apply sufficient granular flux to the welding seam.

- Connect the conductive mouth and welding parts to the welding power source to create a welding arc.

- Automatically feed the wire and move the arc to perform the welding.

The main characteristics of SAW include:

- Unique arc performance

- Good weld quality with high slag isolation for air protection

- Main components of the arc are CO2

- Significant reduction in the nitrogen and oxygen content in the weld metal.

The welding parameters are automatically adjusted for optimal results, the arc walking process is mechanized for efficiency, the metallurgical reaction is sufficient for a stable weld composition, and the anti-wind ability is strong to maintain stability. This results in a stable weld composition and good mechanical properties.

In addition, the working conditions are favorable, with good welding slag isolation and low labor intensity. The electric field intensity of the arc column is relatively high, offering advantages over traditional fusion electrode methods. Furthermore, the equipment has excellent regulation performance.

The high electric field intensity of the arc column enhances the sensitivity of the automatic regulation system, leading to a more stable welding process. Additionally, it has a high minimum welding current.

The shortening of the wire conduction length results in a significant increase in current and current density, improving the penetration ability of the arc and the deposition rate of the welding wire. This, in turn, leads to a high production efficiency.

The thermal insulation provided by the flux and slag also significantly increases the total thermal efficiency and speeds up the welding process.

Scope of Application:

Submerged arc welding is suitable for long and thick plate structure welding due to its depth, high productivity, and mechanical efficiency.

It is widely used in industries such as shipbuilding, boiler and pressure vessel manufacturing, bridge construction, heavy machinery manufacturing, marine structures, and more.

Not only can it be used for connecting components in metal structures, but it can also be used for depositing on the surface of the base metal.

With advancements in welding metallurgy and materials technology, the range of materials that can be welded with submerged arc welding has expanded from carbon structural steel to include low alloy steel, stainless steel, heat-resistant steel, and non-ferrous metals such as nickel base alloys, titanium alloys, and copper alloys.

However, there are some limitations to its application, including:

(1) Welding position limitations: Due to the need to retain flux, submerged arc welding is mainly used for horizontal position welding. It cannot be used for horizontal, vertical, or inverted welding without special measures.

(2) Welding material limitations: Submerged arc welding cannot be used to weld metals such as aluminum and titanium, which are mainly used for black metal welding.

(3) Suitable only for long seam welding: It is not suitable for welding seams in limited spaces.

(4) No direct observation of the arc.

(5) Not suitable for thin plate or low current welding.

3 Tungsten electrode gas shielded arc welding.

This is a Tungsten Electrode Gas Shielded Arc Welding (TIG welding) process that does not involve melting the polar gas.

The weld is created by using an electric arc to melt the metal between the tungsten electrode and the workpiece.

During the welding process, the tungsten electrode remains intact as it is highly refractory, and only the electrode is used.

The tungsten electrode is protected by a shielding gas, such as argon or helium, that is emitted from the torch nozzle.

Supplementary metals can be added as required.

TIG welding is widely recognized as a highly effective method for welding sheet metal and backing welding, as it offers precise control over heat input.

This welding process can be used for nearly all metal connections, especially for metals such as aluminum and magnesium that tend to form refractory oxides, as well as reactive metals like titanium and zirconium.

The weld quality produced by TIG welding is excellent, although the welding speed is slower compared to other electric arc welding methods.

4 Gas metal arc welding

Arc welding is a fusion welding process that uses an electric arc as a heat source. The arc is generated between the continuous welding electrode and the workpiece, creating a molten pool that mixes with the parent metal. After the arc is removed, the weld solidifies and forms a bond with the parent material through metallurgical means.

Characteristics of CO2 Welding:

- Strong compression effect on the arc: CO2 decomposes into CO, O2, and O under the high temperature of the welding arc, causing the arc to have a small diameter. This can make it difficult to cover the end of the welding tip, leading to larger transition resistance and coarser droplets with a less axial transition path and higher splatter rate.

- Good protection of the welding zone: CO2 is commonly used as the shielding gas due to its high density. After thermal decomposition, the increased volume provides better protection.

- Concentrated energy and high penetration ability: CO2 welding provides relatively concentrated energy and strong penetration ability.

- Low cost and energy-efficient: CO2 welding is relatively low cost and energy-saving.

- Good visibility in the welding area: The process and technology provide good visibility in the welding area, making it easier for observation and operation. The welding heat affected zone and deformation are also small.

Metallurgical Characteristics:

- Oxidation of alloy elements: When alloy elements are oxidized during CO2 welding, CO2 decomposes into CO, O2, and O under the action of the arc temperature. CO is insoluble in metal and does not react, while CO2 and O have strong oxidizing properties that oxidize Fe and other alloy elements.

- Deoxidation and alloying of the weld metal: A deoxidizer is typically added to the wire to deoxidize it, and the residual deoxidizer remains in the welding seam as an alloy element to compensate for oxidation loss and ensure the chemical composition of the weld.

Droplet Transition:

- Short circuit transition: Suitable for sheet welding in all positions and characterized by short arcs, thin wires, and small currents.

- Fine grain transition: Characterized by thick wires, long arcs, and large currents and suitable for welding with a fine grain structure.

- Submerged arc droplet transition: Rarely used.

Scope of Application:

CO2 gas shielded welding is widely used in industries such as locomotive manufacturing, shipbuilding, automobile manufacturing, and coal mining machinery manufacturing. It is suitable for welding low carbon steel, low alloy steel, and low alloy high strength steel, but not suitable for welding non-ferrous metals or stainless steel. Although CO2 gas shielded welding can be used for welding stainless steel, it is not the preferred method.

5 Plasma arc welding

Water cooling nozzles and other measures can reduce the area of the arc column, which leads to an increase in the temperature, energy density, and plasma flow rate of the arc. This type of arc, which is compressed by an external constraint, is called a plasma arc.

A plasma arc is a special kind of arc that has a high energy density and is a gas conduction phenomenon. Plasma arc welding is a method of heating and melting the workpiece and base material using the heat of the plasma arc.

Classification: There are two types of plasma arc welding, perforated plasma arc welding and microbeam plasma arc welding.

Perforated plasma arc welding:

This welding method uses a current of 100 to 300 amps and does not require an open groove or clearance. The plasma arc completely melts the welding parts and creates a small through-hole. The molten metal is then pushed around the hole, and the weld is formed at the rear position, resulting in single-side welding. The maximum welding thickness for carbon steel is 7mm and for stainless steel is 10mm.

Microbeam plasma arc welding:

This welding method uses a current of 0.1 to 30 amps and can be used for welding thicknesses of 0.025 to 2.5mm. It can be used for thick plate deep fusion welding or thin plate high-speed welding and surfacing welding, solving the problems of AC (variable polarity) plasma arc welding and aluminum alloy plasma arc welding.

The main technical parameters of plasma arc welding include welding current, welding speed, shielding gas flow, ion gas flow, welding nozzle structure and aperture, etc.

Plasma arc cutting:

In this process, the metal is melted by the high-temperature arc flow of the plasma arc. The molten material is then blown away from the base with the help of a high-velocity stream or current, resulting in an incision.

Features:

- The high energy density of the plasma arc, high temperature of the arc column, and strong penetrating ability allow for welding through double-face forming without an open groove for 10 to 12mm thick steel. This results in fast welding speed, high productivity, and low-stress deformation.

- The weld section has a wine glass shape and does not have the finger-like penetration problem.

- The arc is straightened, and the fluctuation of the molten pool is small due to the influence of long arc length fluctuation.

- The arc stability is 0.1 amps, and has a relatively flat static characteristic, making it well suited for welding thin plates (0.1mm) with a constant current source.

- Tungsten internal shrinkage is used to prevent weld tungsten.

- Small hole welding technology is used to achieve single-side welding and double-side forming.

- The equipment is more complex and requires more gas, making it only suitable for indoor welding. The accessibility of the welding gun is worse than TIG.

- The arc diameter is small, and the welding gun axis and seam center line are more accurate for alignment.

Metallurgical reaction: The reaction is single and only results in evaporation.

Power supply:

A steep drop power supply with DC positive connection is used. When welding aluminum magnesium, an AC steep drop power supply is required with a steady arc measure.

Welding materials: Protective gas and tungsten electrode.

Application:

Plasma arc welding is widely used in industrial production, particularly in aerospace and other military and advanced industrial technologies. It is applied for welding copper and copper alloys, titanium and titanium alloys, alloy steel, stainless steel, molybdenum, and other types of metal, such as the missile shell of titanium alloy. Its versatility and efficiency make it a valuable tool in industrial production, and its high energy density and strong penetrating ability make it suitable for welding thick and difficult-to-reach materials.

6 Flux-cored welding

The tubular wire arc welding, also known as flux cored wire arc welding, is used to weld the combustion arc between the welding wire and the workpiece. It falls under the category of gas metal arc welding.

The welding wire used is a tubular wire filled with different flux components. The process utilizes a protective gas, mostly CO2, to shield the weld. The flux is decomposed or melted during the welding process to protect the molten pool, the alloy, and the arc.

The use of a flux cored wire in the tubular wire arc welding offers additional metallurgical benefits over traditional arc welding.

This welding method can be utilized in the welding of most black metal joints and is widely used in advanced industrial countries.

02 Fusion welding

Gas welding is a fusion welding method that uses heat generated by combustible gases, such as acetylene or liquefied petroleum gas, to melt the parent material through combustion with oxygen. The heat source for this method is a gas flame.

Most commonly, the oxygen-acetylene flame is used, which is made from acetylene gas. This method is easy to operate, but has low heating speed and productivity, a large thermal influence area, and can result in significant deformation.

Gas welding can be used for welding various ferrous metals, nonferrous metals, and alloys. For example, the combustion of acetylene in an oxygen flame can reach a temperature of 3200°C.

There are three types of oxyacetylene flames:

① Neutral flame: The mixture ratio of oxygen and acetylene is 1:1.2, with acetylene fully burned, making it suitable for welding carbon steel and non-ferrous alloys.

② Carbon flame: The mixture ratio of oxygen and acetylene is less than 1, with an excess of acetylene, making it suitable for welding high carbon steel, cast iron, and high-speed steel.

③ Oxidizing flame: The mixture ratio of oxygen and acetylene is greater than 1.2, with an excess of oxygen, making it suitable for brazing brass and bronze.

Gas welding has some obvious disadvantages, such as a low oxyacetylene flame temperature, slow heating, wide heating area and welding heat-affected zone, and a tendency for large welding deformation. Additionally, the protection of the molten metal during the welding process is poor, making it difficult to guarantee the welding quality. As a result, it has limited applications.

However, gas welding has the advantages of not requiring a power supply, simple equipment, low cost, convenient mobility, and strong versatility. Thus, it has practical value in situations without power and in fieldwork.

At present, gas welding is mainly used for welding thin steel plates (0.5-3mm thickness), copper and copper alloys, and cast iron.

2 Air Pressure Welding

Air Pressure Welding is similar to Gas Welding. In this method, the ends of the two butt joints are heated to a certain temperature and then subjected to sufficient pressure to achieve a strong connection. This is a solid phase welding method that does not require filler metal.

Air Pressure Welding is often used in rail welding and steel reinforcement welding.

Electroslag Welding is a welding method that uses the thermal energy of slag. The welding process takes place in a vertical position, with the gap between the two workpiece ends and the water-cooled copper sliding blocks on both sides. The ends of the workpiece are melted by the resistance heat generated by the current passing through the slag.

Electroslag welding is classified into three types based on the electrode shape used in welding: wire electrode electroslag welding, plate electrode electroslag welding, and welding nozzle electroslag welding.

Characteristics of Electroslag Welding:

- Unlike Submerged Arc Welding, Electroslag Welding has a stable electroslag process during the welding process in addition to the initial stage.

- Advantages: It can be used for welding of various steel structures and castings. It has a high productivity and can weld workpiece thicknesses from 30mm to over 1000mm. It is mainly used for butt joint and T-connector welding.

Limitations of Electroslag Welding:

- Due to the large welding pool, the heating and cooling are slow, resulting in the potential for overheating and forming a large grain structure in the weld and heat-affected areas.

- Electroslag welding is limited to vertical welding and is not suitable for workpieces with a thickness below 30mm or with too long of a weld.

Classification and Application:

Classification of Electroslag Welding:

- Electroslag welding, plate electrode electroslag welding, and tube electrode slag welding. The most commonly used method is electroslag welding.

- The electrode is made of wire, with the number of wires used depending on the thickness of the welding parts. Single wire welding can be used for parts with a thickness of 40-60mm, while three wire swing can be used for parts up to 450mm thick.

Application:

- Electroslag welding is mainly used in heavy machinery manufacturing, forging, and casting, such as the welding of heavy-duty machine bases and high-pressure boilers with a thickness of 40-450mm and made of materials such as carbon steel, low alloy steel, and stainless steel.

4 Electron Beam Welding

Electron beam welding is a welding method that uses the heat generated from the concentrated high-speed electron beam bombardment of the workpiece surface.

When electron beam welding is performed, the electron beam produces electrons and accelerates them.

The three most common types of electron beam welding are high vacuum electron beam welding, low vacuum electron beam welding, and non-vacuum electron beam welding.

The first two are carried out in a vacuum chamber, but the welding preparation time (mainly the vacuum time) is longer and the workpiece size is limited by the size of the vacuum chamber.

Compared to electric arc welding, electron beam welding has several key features, including deeper weld depth, narrower weld width, and higher metal purity in the weld.

It is capable of welding very thin materials with precision and can also be used to weld very thick plates (up to 300mm in thickness).

All metals and alloys that can be welded with other welding methods can also be welded with electron beam welding.

It is mainly used for welding high-quality products and is also capable of welding heterogeneous metals, oxidized metals, and refractory metals. However, it is not suitable for mass production.

Electron Beam Welding Machine:

The core component of the machine is the electron gun, which generates electrons, forms the electron beam, and converges the beam.

The electron gun consists of a filament, cathode, anode, and focusing coil.

The filament is heated when charged with electricity and heats the cathode. When the cathode reaches approximately 2400K, electrons are emitted. The electrons are accelerated (to about half the speed of light) through the high voltage electric field between the cathode and anode, and then injected through the anode hole. The focusing coil then converges the electrons into an electron beam with a diameter of 0.8 to 3.2mm, which is directed towards the weldment. The kinetic energy of the beam is converted into thermal energy on the surface of the welding piece, causing the joint of the welding parts to melt rapidly and form a weld after cooling and crystallization.

Based on the vacuum level in the welding workshop, electron beam welding can be divided into three categories:

(1) High Vacuum Electron Beam Welding:

The studio and the electron gun are located in the same room, and the vacuum level is between 10-2 and 10-1pa. This type of welding is suitable for precision welding of refractory, active, high purity metals, and small parts.

(2) Low Vacuum Electron Beam Welding:

The studio and the electron gun are located in separate vacuum chambers, and the vacuum level in the studio is between 10-1 and 15Pa. This type of welding is suitable for larger structural parts and refractory metals that are not sensitive to oxygen and nitrogen.

(3) Non-Vacuum Electron Beam Welding:

The distance between the welding parts and the electron beam outlet should be kept at about 10mm to reduce scattering caused by collisions between the electron beam and gas molecules. Non-vacuum electron beam welding is suitable for welding carbon steel, low alloy steel, stainless steel, refractory metals, copper, aluminum alloys, etc.

Advantages of Vacuum Electron Beam Welding:

(1) The electron beam has a high energy density, reaching up to 5 x 108W/cm2, which is about 5000 to 10,000 times that of a typical arc. It provides heat concentration, high thermal efficiency, and a small thermal influence area, resulting in narrow weld beads and minimal welding deformation.

(2) Welding in a vacuum environment prevents the metal from interacting with the gas phase, resulting in higher joint strength.

(3) The focus radius of the electron beam can be adjusted to be large or small, making it flexible and adaptable. It can weld thin pieces as small as 0.05mm and also weld plates with thicknesses ranging from 200 to 700mm.

Applications:

Electron beam welding is particularly suitable for welding refractory metals, active or high purity metals, and thermal-sensitive metals. However, the equipment is complex and expensive, and the size of the welding parts is limited by the vacuum chamber. Assembly precision must be high and X-rays are easily excited. Additionally, the welding auxiliary time is long, resulting in low productivity. These weaknesses limit the widespread use of electron beam welding.

Laser welding is a process that uses a focused beam of high-power, coherent, monochromatic photons. There are two types of laser welding: continuous power laser welding and pulse power laser welding.

One of the benefits of laser welding is that it can be performed without a vacuum. However, it does not have as strong penetration as electron beam welding. The precise energy control possible during laser welding allows for the welding of precise microdevices. It can be applied to a variety of metals, particularly refractory metals.

Laser generation occurs when the material is stimulated and the wavelength, frequency, and direction of the laser beam are precisely aligned. Laser beams have the characteristics of good monochromaticity, good directionality, and high energy density. When focused through a transmission or reflector, the beam can have a diameter of less than 0.01mm and a power density of 1013W/cm2. This beam can be used as a heat source for welding, cutting, drilling, and surface treatment. The materials used to generate the laser include solid, semiconductor, liquid, and gas, with solid yttrium aluminum garnet (YAG) lasers and CO2 gas lasers being commonly used for welding and cutting processes.

The main advantages of laser welding include:

- The ability to transmit the laser through optical fiber, prisms, and other optical methods, making it suitable for welding small parts and hard-to-reach areas. It can also be soldered through transparent materials.

- High energy density, which enables high-speed welding and results in a small heat-affected area and minimal welding deformation, making it ideal for welding heat-sensitive materials.

- Immunity to electromagnetic fields and no X-ray production, eliminating the need for vacuum protection and making it suitable for welding large structures.

- The ability to directly weld insulated conductors without removing the insulation layer in advance, as well as to weld heterogeneous materials with large differences in physical properties.

The main disadvantages of laser welding include:

Expensive equipment and a low energy conversion rate (5% to 20%).

High machining, assembly, and positioning requirements for the welding parts.

At present, laser welding is primarily used in the electronics and instrument industries for welding microdevices, as well as for welding silicon steel sheets and galvanized steel plates.

03 Pressure Welding

1 Resistance Welding

Resistance welding is a method of welding that uses resistance heat as its energy source. This includes electroslag welding, where the slag resistance heat is used as the energy source, and resistance welding, where the solid resistance heat is used as the energy source.

The process of resistance welding involves applying pressure to the workpiece using electrodes, and using the resistance heat generated by passing an electric current through the workpiece to melt the contact surface and connect the workpiece.

A large current is typically used for this type of welding, and pressure must always be applied to prevent an arc from forming on the contact surface and to ensure that the weld metal is properly welded.

The surface of the welder is crucial to achieving stable welding quality in this type of welding. To ensure this, the electrode, workpiece, and the contact surface between the workpiece must be cleaned before welding.

Advantages:

- The molten core is always surrounded by a plastic ring, which separates it from the air and makes the metallurgical process simple.

- The heating time is short, the heat is concentrated, the thermal effect area is small, and the deformation and stress are minimal. Post-weld calibration and heat treatment is usually not required.

- No filler metal, such as welding wire or rod, or welding materials like oxygen, acetylene, and argon, is required, resulting in low welding costs.

- The operation is simple, making it easy to automate and improve working conditions.

- The productivity is high and there is no noise or harmful gas produced. In mass production, the assembly line can be integrated with other manufacturing processes.

Disadvantages:

- There is currently no reliable non-destructive testing method, so welding quality can only be checked through destructive testing of process samples and workpieces, as well as various monitoring techniques.

- The lap joints and welding seams of the joint increase the weight of the components and reduce the tensile strength and fatigue strength of the joint due to the angle between the two plates.

- The high power of the equipment and the high degree of automation make it expensive and difficult to maintain. The common high-power single-phase AC welding machine can also have a negative impact on the normal operation of the power grid.

Application:

Resistance welding is widely used in the automobile, airplane, instrument, electrical appliance, steel bar, and other industries. It can be used on a variety of materials, although the welding process may vary slightly depending on the resistance of the material.

It is mainly used for thin plate components with a thickness less than 3mm, and can be used to weld all types of steel, aluminum, magnesium, and other non-ferrous metals and their alloys, as well as stainless steel.

Friction welding is a solid-phase welding method that uses mechanical energy.

It works by generating heat through mechanical friction between two surfaces to achieve a metal connection.

The heat generated in friction welding is concentrated at the joint surface, leading to a narrow thermal influence area.

Pressure is applied between the two surfaces, most of which increases towards the end of the heating process, allowing the hot metal to be combined with top forging, without melting the normal combination surface.

Friction welding is highly productive and can be used to weld almost all metals that can be hot-wrought together. It is also suitable for welding heterogeneous metals.

It is ideal for workpieces with a diameter of 100mm. The heat generated by the friction between the contact ends of the welding parts causes the end face to reach a thermoplastic state, and then rapid top forging force is applied to achieve solid-phase welding.

Advantages of Friction Welding:

- Stable welding quality, with high dimensional accuracy of the welding parts and a lower scrap rate than resistance welding and flash butt welding.

- High welding productivity, 5 to 6 times higher than flash butt welding.

- Suitable for welding heterogeneous metals such as carbon steel, low alloy steel, stainless steel, high-speed steel, copper-stainless steel, copper-aluminum, aluminum-steel, steel-zirconium, etc.

- Low processing cost, power-saving, and no special cleaning of welding parts required.

- Easy to automate and simplify the operation, with no sparks, arcs, or harmful gases produced during the welding process.

Disadvantages:

- Non-circular sections are difficult to weld by rotating the workpiece.

- Discs and thin-walled pipe fittings are difficult to weld due to difficulties in clamping.

- The maximum cross-section of friction welding is limited to 20000mm2 due to the motor power of the welding machine’s main shaft.

- Friction welding machines have a high one-time investment cost and are best suited for mass production.

Applications:

Friction welding is used in a variety of applications, such as:

- Heterogeneous metals and exotic steel products, such as copper-aluminum transition joints in the power industry and high-speed steel-structural steel tools for metal cutting.

- Structural steel products, such as power station boilers, valves, and tractor bearings.

Diffusion welding is a solid-phase welding method that uses indirect heat energy. It is typically performed in a vacuum or protective atmosphere.

During the welding process, the surfaces of the two workpieces are exposed to high temperatures and pressure for a set period of time, resulting in the atoms diffusing and combining.

Before welding, it is crucial to clean the surface of the workpiece of any impurities, such as oxides, and ensure that the surface roughness is below a certain level for optimal welding quality.

In a vacuum or protective atmosphere, diffusion welding is performed at a specific temperature (lower than the melting point of the parent metal) and pressure. This results in a bright and clean welding surface with uniform joint components and tissues, reducing the stress corrosion tendency. The welding has minimal deformation and high joint precision, making it suitable for final assembly connections.

Advantages:

- Diffusion welding can be performed on various materials, including heterogeneous materials, without damaging their properties and can be used to create double or multi-layer composite materials.

- It can be used to weld workpieces with complex structures and large thickness differences.

- The joint components and tissues are uniform, reducing the stress corrosion tendency.

- The welding deformation is minimal and the joint precision is high, making it suitable for final assembly connections.

- It can be performed simultaneously with other processing technologies, such as vacuum heat treatment, improving productivity by welding multiple joints at once.

Deficiencies:

- Diffusion welding requires a high level of surface processing and cleaning, has a long welding time, low productivity, and high cost due to the large investment in equipment.

Applications:

- Welding between different melting points or incompatible metals in metallurgy.

- Welding of metal and ceramics.

- Welding of structural parts made of titanium, nickel, and aluminum alloys.

Diffusion welding is used in advanced industries such as atomic energy, aerospace, and electronics, as well as in the general machinery manufacturing industry.

04 Brazing

Brazing energy can be generated through either chemical reaction heat or indirect heat energy. The brazing filler metal is a metal with a lower melting point than the material being welded and is melted by heating. The capillary tube is used to insert the filler metal into the gap between the connector surfaces, wetting the metal surfaces. The solder joint is formed through the mutual diffusion of the liquid and solid phases.

Thus, brazing is a welding method that involves both solid and liquid phases.

Characteristics and Applications of Brazing:

Brazing has a minimal effect on the physical and chemical properties of the parent material. Welding stress and deformation are minimal, making brazing suitable for welding different types of metals with varying welding properties. Multiple weld lines can be completed at once, resulting in a neat and tidy connector. The equipment used is simple and the investment required for production is low. However, the strength of the brazing head is weak and it has poor heat resistance.

Applications of brazing include carbide cutters, drill bits, bicycle frames, heat exchangers, catheters, and various types of containers. It is also the only feasible connection method in the manufacture of microwave waveguides, vacuum tubes, and electronic vacuum devices.

Brazing Filler Metal and Flux:

The filler metal, also known as the solder, is the key component of the brazing head and plays a major role in determining the quality of the brazing head. The filler metal should have an appropriate melting point, good wettability and joint strength, and should be able to spread evenly with the parent material. It must also have sufficient mechanical properties and physical and chemical properties to meet the joint performance requirements.

Brazing is divided into two types based on the solder melting point: soft brazing and hard brazing.

(1) Soft Brazing

Soft brazing is referred to as soldering with a solder melting point lower than 450°C. The commonly used solder for this type of brazing is tin-lead solder, which has good wettability and conductivity. Soft brazing is widely used in electronic products, electrical appliances, and automotive parts, with a joint strength of 60 to 140 MPa.

(2) Hard Brazing

Hard brazing refers to soldering with a solder melting point higher than 450°C. The commonly used brazing filler metals include brass solder and silver-based solder. Silver-based filler results in a joint with high strength, conductivity, and corrosion resistance, but with a higher cost due to the low melting point of the solder and the requirement for good technology. Hard brazing is used for welding parts with higher requirements, such as heavy steel and copper alloy workpieces, as well as tool brazing, with a strength of 200 to 490 MPa.

Note:

The parent material’s contact surface should be thoroughly cleaned, requiring the use of flux. The role of the flux is to remove oxides and oil stains on the surface of the parent material and solder, protect the solder and parent material from oxidation, and improve the wettability and capillary fluidity of the solder. The melting point of the flux should be lower than that of the solder. The commonly used flux for soft soldering is rosin or a zinc chloride solution, while borax, boric acid, and an alkaline fluoride mixture are commonly used fluxes.

Brazing can be divided into several categories based on the heat source or heating method, including flame brazing, induction brazing, dip brazing, resistance brazing, and more.

Due to the low heating temperature, the workpiece material’s performance is minimally affected and the stress deformation of the welded parts is reduced. However, the strength of the brazed joint is generally low and it has poor heat resistance.

Heating Methods for Brazing:

Almost any heat source can be used for brazing, and the soldering process is classified accordingly.

Flame Brazing:

Hard brazing of carbon steel, stainless steel, hard alloys, cast iron, copper and copper alloys, and aluminum and aluminum alloys is achieved through heating with a gas flame.

Induction Brazing:

The welding parts are heated through the resistance heat generated by an alternating magnetic field. This method is applied to welding parts with symmetrical shapes, particularly for pipe shafts.

Dip Brazing:

The welding part or the entire piece is immersed in a molten salt mixture or solder melt, and the brazing process is carried out through the heat of the liquid medium. This method is characterized by rapid heating, uniform temperature, and minimal deformation of the welding parts.

Furnace Brazing:

A resistance furnace can be used to protect the welding parts by vacuuming or reducing the gas or inert gas.

Other brazing methods include soldering iron brazing, resistance brazing, diffusion brazing, infrared brazing, reaction brazing, electron beam brazing, laser brazing, and more.

Brazing can be used to weld carbon steel, stainless steel, high-temperature alloys, aluminum, copper, and other metal materials, as well as to connect heterogeneous metals, metals and non-metals. It is suitable for welding joints with little to no room temperature, particularly for precision, micro, and complicated soldering.

05 Other welding introductions

1 High-Frequency Welding

High-Frequency Welding is a method of solid-phase resistance welding that utilizes the energy generated by solid resistance heat. When welding, the high-frequency current creates heat within the workpiece, causing the surface layers of the welding area to melt or reach a state close to melting. This is then followed by the application of (or without the application of) an upset forging force to combine the metals.

There are two types of High-Frequency Welding: contact high-frequency welding and induction high-frequency welding. In contact high-frequency welding, the high-frequency current is passed into the workpiece through direct contact, while in induction high-frequency welding, an external induction coil generates the current within the workpiece.

High-Frequency Welding is a specialized welding method that requires specialized equipment. It is known for its high productivity, with a welding speed of up to 30m/min. This method is commonly used to weld longitudinal or helical joints in pipes.

2 Explosion Welding

Explosion Welding is another type of solid-phase welding method that utilizes the energy generated by chemical reactions. However, it uses the energy produced by explosive explosions to bond metal.

During an explosion, two pieces of metal can be rapidly brought together to form a metal bond in less than a second. Out of all the welding methods, explosion welding has the widest range of metal combinations that can be welded together. It is possible to use this method to weld two metals with incompatible metallurgical properties into various transition joints.

Explosion Welding is primarily used for flat coverings with a large surface area and is an efficient way to make composite boards.

3 Ultrasonic Welding

Ultrasonic Welding is another type of solid-phase welding method that utilizes mechanical energy. In this method, the welding workpiece is subjected to low static pressure, and the high-frequency vibrations emitted by the acoustic pole generate strong friction and heat at the joint surface, resulting in the bonding of the metals.

Ultrasonic welding can be used for welding most metal materials, including metal to metal, heterogeneous metal, and metal to non-metal. This method is particularly useful for the repeated production of thin plate metal joints with wire, foil, or plate with a thickness of 2 to 3mm.

Welding new process, new technology.

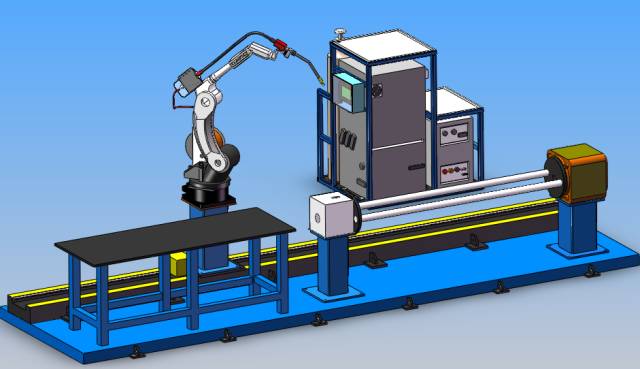

The remarkable advancement in welding technology is reflected in the evolution of the welding process from mechanization to automation, intellectualization, and informatization.

The implementation of intelligent welding robots is a crucial indicator of the high degree of automation in the welding process.

Welding robots break the traditional approach to welding automation and make it possible to automate small-scale production.

Welding robots are mostly fixed-position arm type machines, and they come in two types: teaching robots and intelligent robots.

Teaching Robots:

These robots are taught to memorize the welding track and parameters, and they strictly follow the instruction program to complete the welding of the product.

With just one instruction, the robot can accurately repeat each step.

These welding robots are widely used and suitable for mass production on assembly lines.

Their main function is to demonstrate the taught repetition. However, they have poor adaptability to changes in the environment.

They are not suitable for small-scale production of large structures on construction sites.

Intelligent Robots:

The starting point, space trajectory, and related parameters of the weld can be automatically determined based on simple control instructions.

According to the current situation, the robot can automatically track the welding trajectory, adjust the welding torch position, modify the welding parameters, and control the quality of the weld.

This is the most advanced type of welding robot, characterized by its dexterity, lightness, and ease of movement.

It can adapt to the welding tasks of different structures and locations, but its practical application is still limited and mainly in the research and development stage.

Spot welding robots make up 50% to 60% of all welding robots. They consist of a robot body, a spot welding system, and a control system.

The robot body has 1 to 5 degrees of freedom, and the control system is managed by the control system and the welding component.

The welding system mainly comprises a welding controller, welding clamp, water, electricity, and other auxiliary parts (for underwater welding).

2 Application of computer software.

The application of computer software in the welding field encompasses several areas, including:

- Computer Simulation:

This includes simulation of the welding thermal process, welding metallurgical process, and welding stress and deformation.

Welding is a complex process that involves arc physics, heat transfer, metallurgy, and mechanics. By simulating all these processes, the computer system can determine the best design scheme, process method, and welding parameters for various structures and materials.

Traditionally, the welding process was determined through a series of experiments or by experience to achieve a reliable and economical welding structure. However, computer simulation has proven the feasibility of using numerical methods to solve problems with a limited number of verification tests. This greatly reduces the need for experimental work and saves manpower, materials, and time.

Computer simulation also plays a crucial role in welding new engineering structures and materials. The level of computer simulation also determines the extent of automation in welding. Additionally, computer simulation is used to analyze the strength and performance of welding structures and joints.

- Database Technology and Expert System:

These are used for welding process design, process parameter selection, welding defect diagnosis, welding cost budgeting, real-time monitoring, welding CAD, welder testing, and more.

Database technology has been integrated into all aspects of welding, from raw materials and welding tests to welding technology and production. Some examples of database systems include welding procedure qualification, welding procedure specification, welder archives management, welding material, material composition and properties, weldability and welding, and welding CCT diagram management and standard consulting systems. These database systems provide favorable conditions for managing various data and information in the welding field.

The welding expert system mainly focuses on process development, defect prediction and diagnosis, computer-aided design, and so on. In current welding expert systems, process selection and development are the most important application areas, and real-time control of the welding process is an important direction for development.

- Computer-Aided Quality Control Technology (CAQ):

This is used for real-time monitoring of product data analysis and welding quality.

Computer-aided design/manufacturing (CAD/CAM) is also increasingly used in the welding process, mainly in NC cutting, welding structure design, and welding robots.

Nice Article.. Thanks For The Sharing..

It’s interesting to know that electroslag welding is commonly used. I think I’ll buy an automatic girth welder from a good supplier since most wires can be used for my project. If it can be used to weld large welding parts, I might be finished before the month ends.

Very informative and useful for manufactureres

Thanks.