Achieving a flawless weld requires more than just skill; it hinges on mastering the interplay between voltage and current. These two parameters are the lifeblood of welding, dictating everything from penetration depth to arc stability. Whether you’re fine-tuning settings for a new project or troubleshooting common issues like spatter or burn-through, understanding how voltage and […]

Achieving a flawless weld requires more than just skill; it hinges on mastering the interplay between voltage and current. These two parameters are the lifeblood of welding, dictating everything from penetration depth to arc stability. Whether you’re fine-tuning settings for a new project or troubleshooting common issues like spatter or burn-through, understanding how voltage and current influence the welding process is essential.

This article unpacks the science and practical application behind these critical factors, guiding you through the optimal adjustments for material type, thickness, and electrode size. From choosing the right parameters to enhance weld quality to resolving common challenges, you’ll gain actionable insights to elevate your welding expertise. If you’ve ever wondered how to strike the perfect balance for precise, dependable welds, you’re in the right place. Keep reading to discover the techniques and best practices that will transform your approach to welding.

Voltage and current are key factors in welding that influence the weld’s quality, depth, and stability. These parameters are interconnected and must be precisely controlled to achieve the best welding results.

Voltage in welding is the electrical force that drives the current. It mainly controls the arc length, which impacts the weld bead.

Current, or amperage, is the electrical charge flow that determines heat intensity and weld penetration.

The combination of voltage and current impacts weld quality:

Voltage and current work together to define the arc and overall weld performance:

Understanding and controlling voltage and current is crucial for creating strong, defect-free welds and ensuring efficient welding processes.

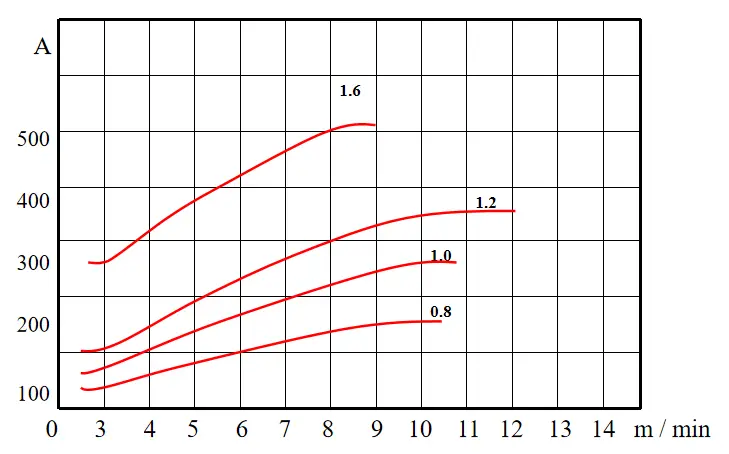

The selection of appropriate welding current is critical in CO2 welding and is determined by various welding parameters, including plate thickness, welding position, welding speed, and material properties. In CO2 welding machines, adjusting the current effectively means modifying the wire feed speed, highlighting the intricate relationship between these two parameters.

It is crucial to maintain a precise balance between welding current and voltage. This equilibrium ensures that the wire feed speed aligns perfectly with the melting rate of the welding wire at the set voltage, thereby maintaining a stable arc length. This synchronization is fundamental for achieving high-quality welds and optimal process efficiency.

The Relationship between Welding Current and Wire Feed Speed:

Understanding and optimizing this relationship is essential for achieving superior weld quality, minimizing defects, and maximizing productivity in CO2 welding applications across various industries.

Welding voltage, also known as arc voltage, is a critical parameter that provides the energy for the welding process. It directly influences the arc characteristics, heat input, and overall weld quality. The relationship between arc voltage and welding energy is proportional: higher arc voltage results in greater welding energy, faster melting of the welding wire, and increased welding current.

The effective arc voltage can be expressed by the following equation:

Arc Voltage = Output Voltage – Voltage Drop

Where:

The voltage drop primarily occurs due to resistance in the welding cables, connections, and the arc itself. When a welding machine is installed according to manufacturer specifications, the most significant source of voltage drop is often the extension of welding cables.

For optimal welding performance, it’s crucial to compensate for voltage drops, especially when using extended welding cables. The following table provides guidelines for adjusting the output voltage based on cable length extensions:

| Welding Current Cable Length | 100A | 200A | 300A | 400A | 500A |

| 10m | Approximately 1V | Approximately 1.5V | Approximately 1V | Approximately 1.5V | Approximately 2V |

| 15m | Approximately 1V | Approximately 2.5V | Approximately 2V | Approximately 2.5V | Approximately 3V |

| 20m | Approximately 1.5V | Approximately 3V | Approximately 2.5V | Approximately 3V | Approximately 4V |

| 25m | Approximately 2V | Approximately 4V | Approximately 3V | Approximately 4V | Approximately 5V |

Note: These values are general guidelines. Actual voltage adjustments may vary based on factors such as cable gauge, material, and specific welding application requirements.

When adjusting welding voltage, it’s important to consider its effects on:

Proper voltage selection and compensation are essential for achieving high-quality welds and maintaining process efficiency in various welding applications.

Select the welding current based on the specific welding conditions and workpiece thickness. Calculate the appropriate welding voltage using the following empirical formulas:

These formulas provide a starting point for voltage selection, which may require fine-tuning based on factors such as material composition, joint configuration, and desired weld characteristics.

Example 1: For a selected welding current of 200A (< 300A):

Welding Voltage = (0.05 × 200 + 14 ± 2) Volts

= (10 + 14 ± 2) Volts

= 24 ± 2 Volts

Recommended voltage range: 22 – 26 Volts

Example 2: For a selected welding current of 400A (≥ 300A):

Welding Voltage = (0.05 × 400 + 14 ± 3) Volts

= (20 + 14 ± 3) Volts

= 34 ± 3 Volts

Recommended voltage range: 31 – 37 Volts

Note: Always consult the welding equipment manufacturer’s guidelines and perform test welds to optimize voltage settings for specific applications. Factors such as shielding gas composition, wire feed speed, and travel speed may influence the optimal voltage selection.

Welding voltage provides the energy necessary for the melting of the welding wire. Higher voltages result in a faster melting speed of the wire. Welding current, on the other hand, is essentially the balanced outcome of wire feeding speed and melting speed. So how should we choose the appropriate welding current?

1) The appropriate welding current value is selected based on factors such as the type of welding rod, plate thickness, and rod diameter.

The current is proportional to both plate thickness and wire diameter. The current (I) can be calculated using the formula I=(35-55)d, where ‘d’ is the rod diameter. For example, if the rod diameter is 4mm, the welding current value is selected between 140-220A.

2) Welding current is selected according to the welding position:

140A for overhead welding seams; between 140-160A for vertical and horizontal butt welding; over 180A for flat butt welding. For all-position welding (inclusive of flat, horizontal, vertical, and overhead positions), the selected welding current should be universal, usually taking the value of vertical welding current. When welding a horizontally fixed pipe for butt joint, the all-position welding current is used, generally taking the value of vertical butt welding current.

3) The current value is selected according to the welding layers:

A smaller current value is generally used for the root layer, a larger one for the filling layer, and the current value for the cover layer is relatively reduced. For example, in flat butt welding, a multi-layer, multi-pass welding approach is usually used.

The root layer is welded with a 150A current, while the filling layer can use a current value between 180-200A. The cover layer uses a reduced current value by 10-15A, to ensure an aesthetically pleasing result and avoid welding defects such as undercut.

4) Choosing welding current based on the type of welding rod and the method of manipulation:

1. According to the type of welding rod: Iacid > Ialkaline > Istainless steel. Acidic electrodes use the highest current value. When the electrode diameter is 4mm, the filler layer of flat butt welding can use a current of 180A.

However, with the same electrode diameter using an alkaline electrode, the welding current needs to be 20A less, i.e., a welding current of 160A. If welding is done with A137 stainless steel electrode, the current should be 20% less, approximately 140A. Otherwise, the welding rod may turn red and the flux layer may peel off halfway through the welding process.

2. Choosing based on manipulation method: Small current values are generally used for drag arc method, while slightly higher current values are used for lift arc method. When doing vertical butt welding or vertical angle welding with a Ф4 alkaline electrode, a drag arc method with 120A may be used, whereas the lift arc method can utilize 135A.

5) Choosing welding current based on production experience:

Look at the spatter, the welding current roughly decides the arc force, more spatter means more arc force; less welding current means less arc force, making it hard to distinguish between slag and molten metal.

Look at the weld formation: higher welding current is likely to cause undercutting, with less reinforcement; lower welding current results in a narrow but high weld. Observe the melting state of the electrode: a higher welding current melts the electrode faster, turning it red; a lower welding current might cause sticking.

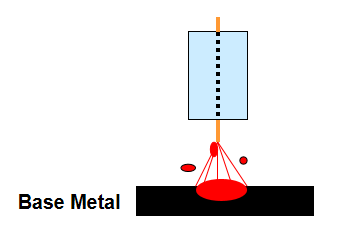

When the voltage is too high:

The arc length increases, spatter particles grow larger, porosity is more likely to occur, the weld bead widens, while the penetration depth and reinforcement decrease.

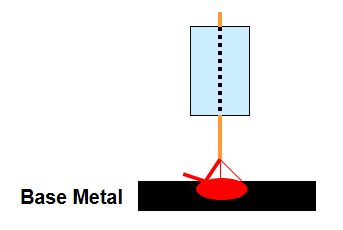

When the voltage is too low:

The welding wire dips into the base material, spattering increases, the weld bead narrows, while the penetration depth and reinforcement increase.

The thickness and type of base material play a crucial role in determining the appropriate welding parameters, including voltage and current settings.

When welding thin materials, lower voltage and current settings are required to prevent burn-through and minimize excessive heat input. For thicker materials, higher settings are necessary to ensure adequate penetration and fusion. The increased heat input helps achieve a strong weld joint by allowing the weld to penetrate deeply into the material.

Steel generally requires moderate voltage and current settings. For example, mild steel welding typically uses 17-19 volts and 200-250 amperes, depending on thickness. Aluminum, due to its high thermal conductivity, needs higher voltage settings for proper heat distribution. Stainless steel should use lower current settings to avoid overheating and preserve its corrosion-resistant properties.

The choice of electrode type and size directly affects the welding parameters and overall weld quality.

Solid wires, often used in Gas Metal Arc Welding (GMAW), need specific voltage and current settings for consistent metal transfer and stable arc characteristics. Flux-cored wires contain flux material that stabilizes the arc and improves weld penetration, requiring different settings than solid wires.

Smaller electrodes are suitable for thin materials and precise welds, needing lower current settings to prevent excessive heat input. Larger electrodes are ideal for thick materials, allowing higher current settings for deeper penetration and faster deposition rates.

Wire feed speed is crucial in processes like GMAW because it directly affects the welding current. Higher wire feed speed increases the current, leading to more heat input and faster deposition rates.

Balancing wire feed speed with the correct voltage is essential for maintaining a stable arc and achieving the desired weld bead. An improper balance can result in defects like spatter or poor penetration.

Following established guidelines and manufacturer recommendations ensures optimal welding performance and quality.

WPS documents provide standardized welding parameters, such as voltage, current, travel speed, and shielding gas requirements, tailored for specific materials and thicknesses. Following WPS ensures consistent welding processes, leading to high-quality welds and minimizing defects.

Manufacturers offer specific guidelines for setting voltage, current, and other parameters based on the equipment and materials used. Following these recommendations helps achieve the best results and extends the life of the equipment. They also provide compatibility information for different electrodes and wires, ensuring optimal performance and preventing mismatched components.

By considering material thickness, type, electrode specifications, and adhering to WPS and manufacturer guidelines, welders can effectively adjust voltage and current settings to achieve high-quality, consistent welds.

Burn-through happens when too much heat causes the base material to melt completely, forming holes in the weld.

Spatter involves molten metal droplets scattering around the weld area, leading to defects and cleanup challenges.

Porosity refers to the formation of small gas pockets or voids within the weld, weakening its structural integrity.

Wire sticking happens when the electrode wire adheres to the base material, interrupting the welding process.

By systematically addressing these common issues and making precise adjustments to voltage, current, and other parameters, welders can achieve consistent, high-quality results while minimizing defects.

Below are answers to some frequently asked questions:

To adjust the voltage and current for MIG welding, you primarily control the wire feed speed (WFS) to set the current and manually set the voltage on the welding machine. Increasing the WFS raises the current, affecting penetration depth and the amount of metal deposited. Voltage adjustments control the arc length and bead width; higher voltage results in a wider, flatter bead, while lower voltage creates a narrower, lumpier bead. Use formulas, such as (U=(0.05I+14)±2V), to estimate appropriate voltage based on current, and make fine adjustments based on visual and auditory cues during welding to achieve optimal weld quality.

Voltage and current significantly influence the weld seam in welding processes. Welding current primarily affects penetration depth and weld reinforcement; higher current increases penetration and thickness but may lead to burn-through, while lower current can result in lack of fusion or porosity. Voltage controls arc length and bead width, with higher voltage creating a wider, flatter bead and lower voltage producing a narrower, thicker bead. Improper settings can compromise weld quality, causing defects like spatter, porosity, or wire sticking. A balanced adjustment of these parameters ensures optimal weld quality and seam integrity.

Material thickness and type significantly influence the settings for welding voltage and current. Thicker materials generally require higher amperage to ensure adequate penetration, with a rough guideline suggesting 1 amp per 0.001 inch of thickness. For instance, welding 1/4-inch steel might necessitate around 250 amps. Conversely, thinner materials need lower amperage to prevent burn-through.

Material type also plays a crucial role due to differences in thermal conductivity and melting points. Aluminum, with high thermal conductivity, often requires lower amperage compared to steel to avoid excessive heat input. For example, 1/8-inch aluminum might need 120-140 amps, while the same thickness of steel would require higher amperage. Additionally, voltage settings must be adjusted accordingly; thicker materials typically need higher voltage to maintain arc stability and achieve proper penetration, whereas materials like stainless steel, which require precise control, might use lower voltage settings.

By understanding these factors and consulting Welding Procedure Specifications (WPS), welders can optimize their voltage and current settings for better weld quality and strength.

The relationship between wire feed speed (WFS) and welding current in Gas Metal Arc Welding (GMAW) is direct and crucial for maintaining a stable welding process. In GMAW, particularly with constant voltage power sources, adjusting the wire feed speed automatically adjusts the welding current. Increasing the wire feed speed increases the welding current, while decreasing the wire feed speed decreases the welding current. This is because the welding machine supplies the necessary current to melt the wire at the rate it is fed. This relationship impacts the metal transfer mode, weld penetration, and bead profile. Higher wire feed speeds lead to higher welding currents, resulting in deeper penetration and possibly changing the transfer mode from globular to spray, depending on the current level and material. Balancing the wire feed rate and burn rate is essential to avoid issues like wire melting back to the contact tip or feeding too quickly into the weld pool.

To determine the optimal voltage and current settings for your welding project, start by consulting the Welding Procedure Specifications (WPS) for recommended ranges based on your material and joint configuration. Consider the material thickness and type, as thicker materials generally require higher currents. Select the appropriate electrode type and size, as they have specific operating ranges for current and voltage. In Gas Metal Arc Welding (GMAW), adjust the wire feed speed (WFS) to control the welding current, ensuring it balances with the voltage to maintain arc stability. Perform test welds on scrap material to evaluate and fine-tune the settings, and monitor welding conditions continuously. Use measurement tools to verify the settings and document the optimal parameters for consistency in future welding tasks.

Improper voltage and current settings in welding can significantly impact weld quality and safety. If the voltage is too high, the weld may be too wide and flat with insufficient penetration, leading to weak joints. Conversely, too low voltage results in shallow, narrow welds with poor fusion. Incorrect current settings can cause issues like burn-through, excessive spatter, and poor arc stability. These defects compromise the weld’s structural integrity, leading to potential failures. Additionally, improper settings increase the risk of electric shock and equipment hazards. Ensuring correct voltage and current settings is crucial for producing strong, defect-free welds and maintaining a safe working environment.