Have you ever wondered what makes hydraulic cylinders so essential in machinery? This article explores their vital role, common issues, and troubleshooting tips. Learn how to keep your equipment running smoothly and avoid costly downtime. Dive in to understand the nuts and bolts of hydraulic cylinders!

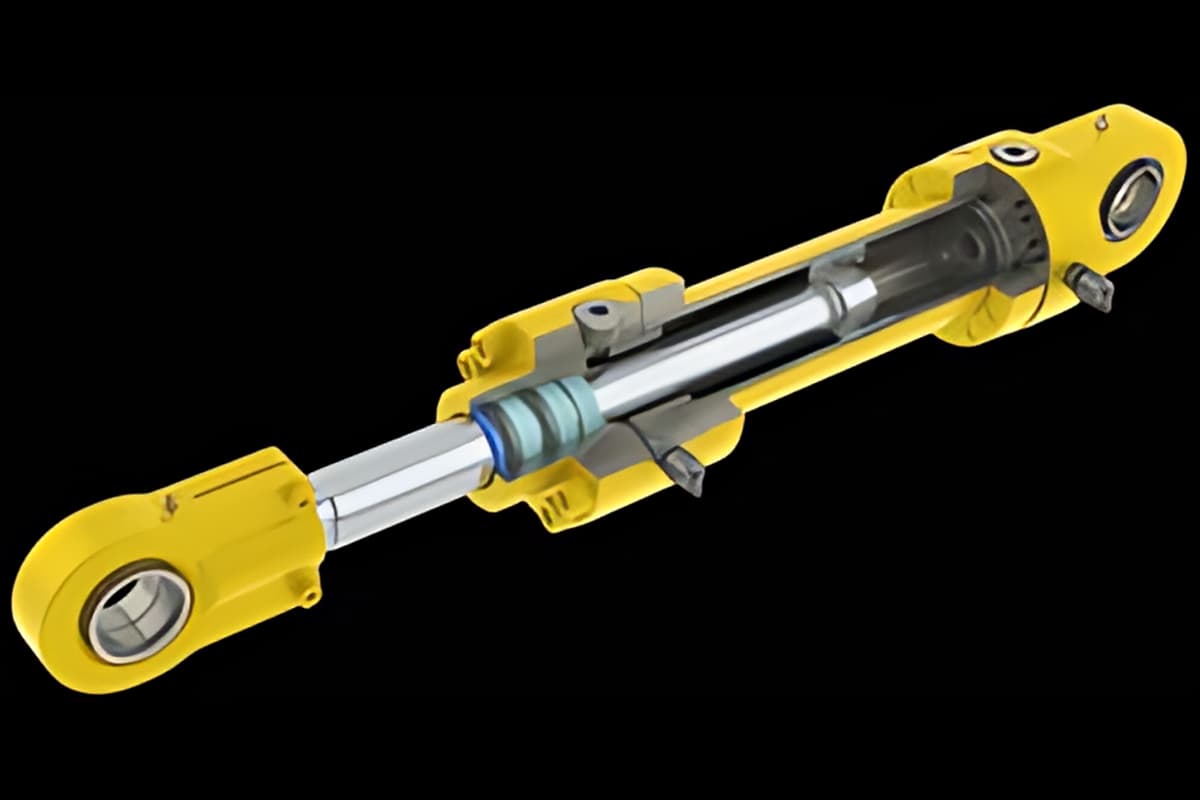

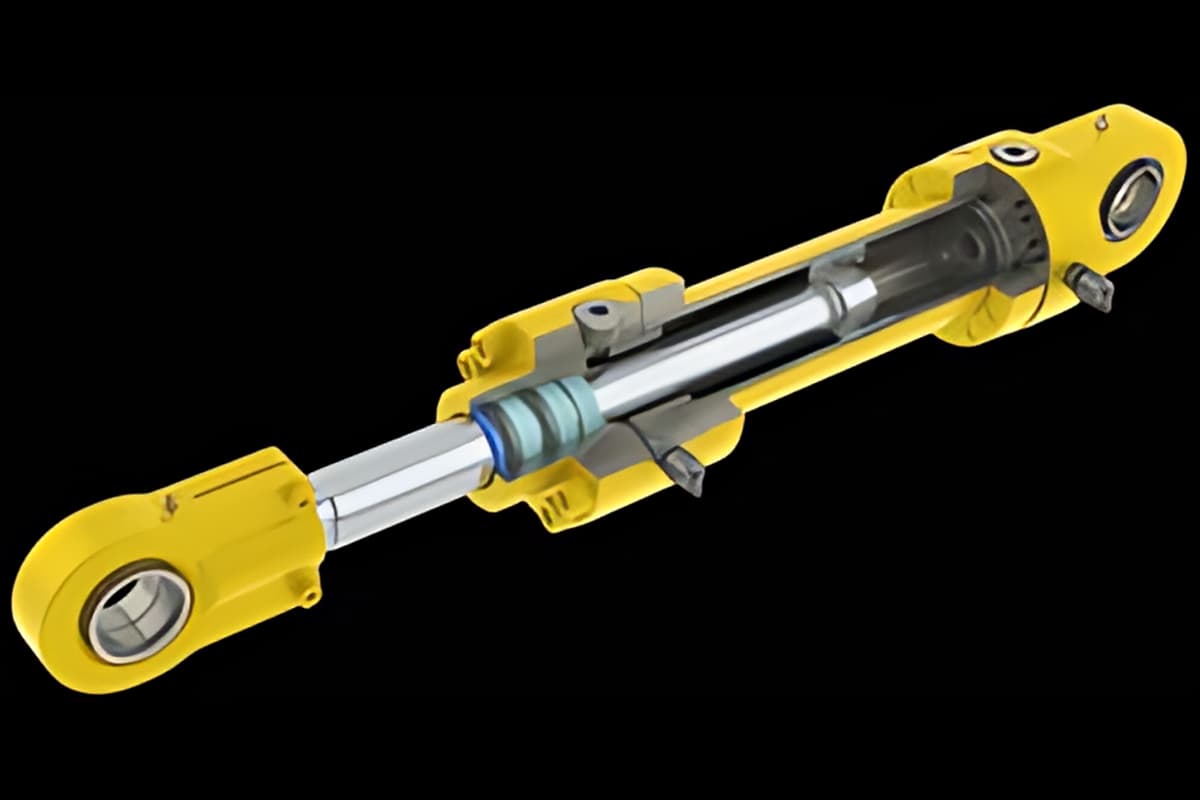

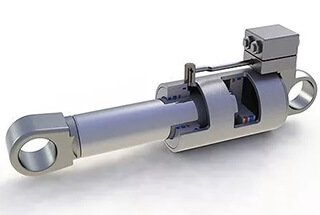

Hydraulic cylinders are sophisticated actuators that harness hydraulic energy to generate mechanical force, typically producing linear reciprocating motion or controlled rotational movement. These devices serve as the muscle of hydraulic systems, converting fluid pressure into powerful, precise linear force.

Key characteristics of hydraulic cylinders include:

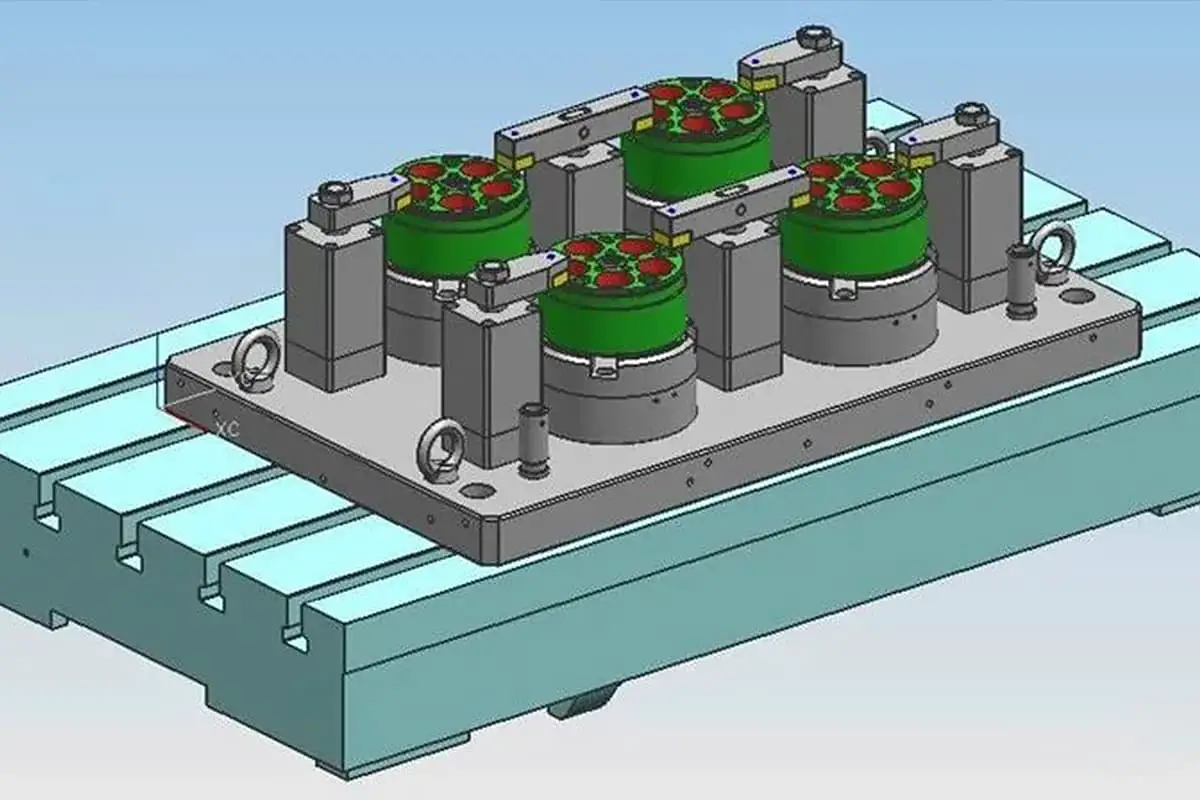

Due to their ubiquity in industrial hydraulics, hydraulic cylinders are integral components in diverse machinery, including construction equipment, manufacturing systems, and aerospace applications.

However, like all mechanical systems, hydraulic cylinders are subject to wear and potential failures. Common issues include:

To maintain optimal performance and prevent costly equipment downtime, regular diagnostic checks and preventive maintenance are crucial. This proactive approach ensures early detection of potential issues, maximizing the cylinder’s operational lifespan and system reliability.

Understanding the principles, applications, and maintenance requirements of hydraulic cylinders is essential for engineers and technicians working with hydraulic systems across various industries.

From a fundamental perspective, the main components that contribute to hydraulic cylinder failures include the oil cylinder, piston rod, cylinder block, guide sleeve, piston, and cylinder rod sealing. These components can be grouped into four categories:

I. Wear and tear on the mating surfaces of the piston and piston rod II. Wear and tear on the mating surfaces of the piston rod and guide sleeve III. Broken piston seals IV. Damage to other seals, etc.

The hydraulic industry widely recognizes that incorrect operation of the hydraulic cylinder is one of the most common fault conditions. To diagnose and resolve this issue, operators must identify the root cause of the failure.

While the hydraulic cylinder is in operation, check if any pressure oil is entering it. If there is no pressure oil entering the cylinder, the causes and solutions are as follows:

If oil is entering the cylinder, verify that the oil pressure is sufficient. If the system is not functioning properly, it is likely due to an issue with the pump or the relief valve. Check and resolve any problems with the pump or relief valve in a timely manner.

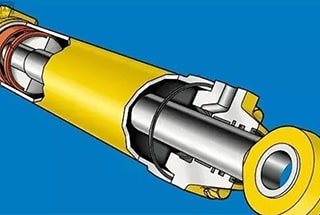

In the case of serious internal leakage, looseness of the piston and piston rod, and serious damage to the seals, tighten the piston and piston rod and replace the seals promptly.

If the pressure regulating valve is faulty, adjust the pressure setting until the required value is reached. If necessary, recalculate the working pressure and replace the pressure regulating component with one that can be adjusted to the desired value.

When the sealing ring on the piston is missing or seriously damaged, or there is a deep groove in the cylinder bore and the nut that locks the piston on the piston rod becomes loose, this will cause severe cavitation in the hydraulic cylinder inlet cavity, resulting in abnormal movement of the components. In this case, replace the sealing ring on the piston and take other necessary repair measures.

If oil is entering the cylinder and the pressure meets the requirements, but the load is too large causing the hydraulic cylinder to be unable to move, several factors should be investigated: