Imagine a world where precision and efficiency blend seamlessly in manufacturing. This is the realm of CNC machines—automated tools guided by digital instructions to shape complex parts with pinpoint accuracy. This article unpacks the essence of CNC technology, tracing its evolution, components, and pivotal role in industries from aerospace to electronics. Dive in to understand how CNC machines revolutionize production, enhancing both speed and quality, and discover the future trends shaping this indispensable technology.

Numerical Control (NC) technology is a machine tool control technology that developed in the mid-20th century. NC is an automatic control technology that uses digital signals to control the movement and machining process of machine tools.

An NC machine tool is a machine tool that uses NC technology, or in other words, a machine tool equipped with an NC system. It is a typical electromechanical integration product that comprehensively applies advanced technologies such as computer technology, automatic control technology, precision measurement technology, communication technology, and precision mechanical technology.

The Fifth Technical Committee of the International Federation of Information Processing (IFIP) has defined NC machine tools as machine tools equipped with program control systems that can logically process programs specified by specific codes and other symbol encoding instructions.

With the continuous progress of social production and science and technology, various new industrial products emerge one after another.

As the foundation of national industry, the mechanical manufacturing industry produces increasingly precise and complex products. Especially in fields such as aerospace, navigation, and military, the required mechanical parts have higher precision, more complex shapes, and often have smaller batches. Processing such products requires frequent equipment modifications or adjustments, which ordinary machine tools or highly specialized automated machine tools are clearly not able to meet.

Meanwhile, with the increasing intensity of market competition, production enterprises urgently need to further improve production efficiency, product quality, and reduce production costs.

In this context, a new type of production equipment – numerical control (NC) machine tools – has emerged. It comprehensively applies various technical achievements such as electronic computers, automatic control, servo drives, precision measurement, and new mechanical structures, forming the foundation of the future mechanical industry and indicating the development direction of mechanical manufacturing industry equipment.

The development of numerical control (NC) machine tools began in the United States. In 1948, Parsons Co. completed a task to manufacture sample check plates for the contour of helicopter propellers and proposed the initial concept of developing NC machine tools. In 1949, with the support of the US Air Force Logistics Department, Parsons Co. officially accepted the commission and cooperated with the Servo Mechanism Laboratory of the Massachusetts Institute of Technology to start the development of NC machine tools.

After three years of research, the world’s first experimental prototype NC machine tool was successfully developed in 1952. It was a milling machine using a linear interpolation three-coordinate continuous control system based on the pulse multiplier principle. The entire NC system used electronic tube components, and the size of the NC device was even larger than that of the machine tool body. After three years of improvement and automatic programming research, the machine tool entered the trial stage in 1955.

Subsequently, other countries such as Germany, the UK, Japan, the former Soviet Union, and Sweden also successively carried out the development and production of NC machine tools. In 1959, Keaney & Trecker in the United States successfully developed a machining center for the first time. It was an NC machine tool equipped with an automatic tool changer and a rotary worktable. It could process multiple planes of a workpiece in multiple processes in one clamping.

However, until the late 1950s, due to factors such as price, NC machine tools were limited to aviation and military industry applications, and most of them were continuous control systems. Until the 1960s, due to the application of transistors, the reliability of NC systems was further improved and prices decreased, and some civil industries began to develop NC machine tools, most of which were point positioning control machine tools such as drilling machines and punch presses.

NC technology not only achieved practical application in machine tools but also gradually spread to welding machines, flame cutting machines, etc., expanding the scope of NC technology applications continuously.

Since the first CNC machine tool was successfully developed in the United States in 1952, CNC machine tools have rapidly developed and continuously updated with the advancement of electronic technology, computer technology, automatic control, and precision measurement. They have gone through five stages of development.

The first generation of CNC machine tools: NC systems using electronic tube components were used from 1952 to 1959.

The second generation of CNC machine tools: NC systems using transistor circuits were adopted since 1959.

The third generation of CNC machine tools: NC systems using small and medium-scale integrated circuits were adopted since 1965.

The fourth generation of CNC machine tools: CNC systems controlled by small general-purpose electronic computers using large-scale integrated circuits were adopted since 1970.

The fifth generation of CNC machine tools: MNC systems controlled by microcomputers were adopted since 1974.

In recent years, as microelectronics and computer technology become more mature, their achievements are constantly penetrating into various fields of mechanical manufacturing. Computer-based direct numerical control (DNC) systems, flexible manufacturing systems (FMS), and computer-integrated manufacturing systems (CIMS) have emerged successively. These advanced automated production systems are based on CNC machine tools, and they represent the future development trend of CNC machine tools.

(1) Direct Numerical Control System

The so-called Direct Numerical Control (DNC) system uses a computer to automatically program several CNC machine tools. The programming results are directly transmitted to the control boxes of each CNC machine tool through data lines.

The central computer has sufficient memory capacity, which enables it to store, manage, and control a large number of part programs. By using a time-sharing operating system, the central computer can manage and control a group of CNC machine tools simultaneously. Therefore, it is also called a computer group control system.

Currently, in the DNC system, each CNC machine tool has its own independent numerical control system and is connected to the central computer network to achieve hierarchical control. It no longer considers having one computer complete all the functions of the numerical control device via time-sharing.

With the development of DNC technology, the central computer not only compiles programs for controlling the machining process of CNC machine tools but also further controls the transportation of workpieces and tools. This forms a computer-controlled CNC machine tool automatic production line, providing favorable conditions for the development of flexible manufacturing systems.

(2) Flexible Manufacturing System

A Flexible Manufacturing System (FMS), also known as a computer group control automatic line, connects a group of CNC machine tools using automatic transmission systems and places them under the unified control of a computer to form an entire manufacturing system.

Its characteristic is that a main computer manages the hardware and software of the entire system. It adopts DNC to control two or more CNC machining centers and schedules and automatically transfers workpieces between various machine tools.

It utilizes devices such as exchange worktables or industrial robots to achieve automatic loading and unloading of parts, enabling the machine tools to operate continuously for 24 hours a day with minimal human supervision. For example, the FMS system of Japan’s FANUC company consists of 60 CNC machine tools, 52 industrial robots, two unmanned automatic transport vehicles, and an automated warehouse. This system can process 10,000 servo motors per month.

(3) Computer Integrated Manufacturing System

A Computer Integrated Manufacturing System (CIMS) is a highly efficient flexible integrated manufacturing system that uses the most advanced computer technology to control the entire process from order placement, design, process, manufacturing to sales to achieve information system integration. It gradually improves on the basis of process automation (e.g., computer-aided design, computer-aided process planning, computer-aided manufacturing, flexible manufacturing systems, etc.) combined with the development of other management information systems.

CIMS has various types of computers and software systems with analysis and control capabilities. It connects all production activities in the factory and ultimately achieves comprehensive automation throughout the entire factory.

There are many types of CNC machine tools, but any type of CNC machine tool is composed of several basic components, including control media, numerical control system, servo system, auxiliary control system, and the machine tool body, as shown in Figure 1-1.

(1) Control Media

When the numerical control system works, it does not require operators to directly manipulate the machine tool, but the machine tool must execute the intentions of the operator. This requires establishing some kind of connection between the operator and the machine tool. The intermediate medium of this connection is called the control medium. The control medium stores all the operation information required for processing the part and the relative displacement information between the tool and the workpiece.

Therefore, the control medium is the information carrier that transmits the part processing information to the numerical control device. There are various forms of control media, which differ depending on the type of numerical control device used. Common ones include perforated paper tape, punched card, magnetic tape, floppy disk, and USB interface media.

The processing information recorded on the control medium needs to be transmitted to the numerical control device through the input device. Common input devices include photoelectric paper tape input machines, magnetic tape recorders, floppy disk drives, and USB interfaces.

In addition to the above control media, some CNC machine tools use digital dials, digital plugs, or directly enter programs and data using a keyboard. In addition, with the development of CAD/CAM technology, some numerical control equipment uses CAD/CAM software to program on other computers, and then communicates with the numerical control system (such as a LAN) to directly transmit the program and data to the numerical control device.

(2) Numerical Control System

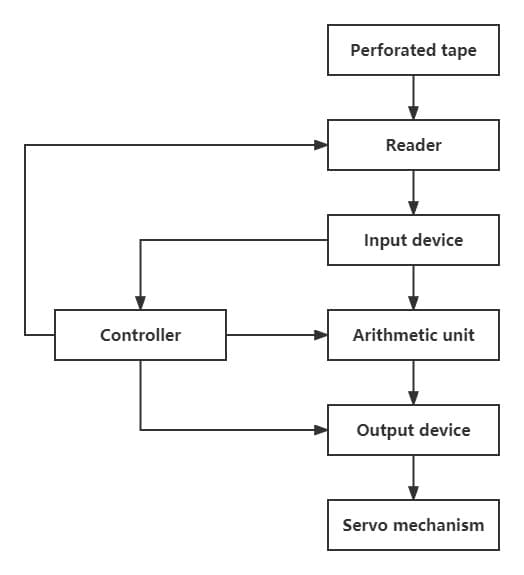

The numerical control device is a control system and the central link of CNC machine tools. It can automatically read the given numbers from the input medium and decode them to make the machine tool feed and machine parts. A numerical control system usually consists of four parts: input device, controller, arithmetic unit, and output device, as shown in Figure 1-2.

The input device receives the code output by the perforated tape reader, and after identification and decoding, inputs them into the corresponding registers. These instructions and data will serve as the raw data for control and operation.

The controller receives instructions from the input device and controls the arithmetic unit and input device according to the instructions to achieve various operations on the machine tool (such as controlling the movement of the worktable along a certain coordinate axis, spindle speed control, and coolant switch, etc.), as well as controlling the working cycle of the entire machine (such as controlling the start or stop of the reader, controlling the operation of the arithmetic unit, and controlling output signals, etc.).

The arithmetic unit receives instructions from the controller, performs certain calculations on the data sent by the input device, and continuously sends the calculation results to the output device to make the servo system perform the required motion.

For the contour control system that processes complex parts, an important function of the arithmetic unit is interpolation. Interpolation means that the coordinate data of a starting point and ending point on the workpiece contour of each program segment are sent to the arithmetic unit, and after calculation, “data densification” is performed between the starting point and ending point, and the calculation results are sent to the output device according to the controller’s instructions.

The output device sends the calculation results from the arithmetic unit to the servo system according to the controller’s instructions, drives the corresponding coordinate axis through power amplification, and makes the machine tool complete the relative motion of the tool and the workpiece.

Currently, microcomputers are used as numerical control devices. The central processing unit (CPU) of the microcomputer, also known as a microprocessor, is a large-scale integrated circuit. It integrates the arithmetic unit and controller on a single integrated circuit chip. In the microcomputer, the input and output circuits use large-scale integrated circuits, which are called I/O interfaces. The microcomputer has large-capacity registers and uses high-density storage media such as semiconductor memory and disk memory.

The memory can be divided into two types: read-only memory (ROM) and random access memory (RAM). The former is used to store the control program of the system, and the latter stores the working parameters during system operation or the user’s part processing program. The working principle of the microcomputer numerical control device is the same as that of the above hardware numerical control device, except that the former uses general hardware, and different functions are achieved by changing the software, making it more flexible and economical.

(3) Servo System

The servo system consists of a servo drive motor and a servo drive device, and it is the executive part of the numerical control system. The servo system receives instruction information from the numerical control system and moves the moving parts of the machine tool or performs actions of the executing part according to the requirements of the instruction information.

In order to process workpieces that meet the required specifications. Instruction information is reflected in pulse information, and the displacement caused by each pulse for the moving parts of the machine tool is called the pulse equivalent. Generally used pulse equivalents in mechanical processing are 0.01mm/pulse, 0.005mm/pulse, and 0.001mm/pulse, and the current pulse equivalent used in numerical control systems is generally 0.001mm/pulse.

The servo system is a key component of the CNC machine tool, and its quality directly affects the speed, position, accuracy, etc. of CNC machining. The commonly used driving devices in the servo mechanism vary depending on the type of numerical control system. In open-loop control systems, stepper motors and electrohydraulic pulse motors are commonly used in servo mechanisms; closed-loop systems use adjustable-speed DC motors and electrohydraulic servo drive devices, etc.

(4) Auxiliary Control System

The auxiliary control system is a strong electrical control device between the numerical control device and the machine tool mechanical and hydraulic components. It receives instruction signals such as main motion speed change, tool selection exchange, and auxiliary device action output by the numerical control device, and after necessary compilation, logical judgment, and power amplification, directly drives the corresponding electrical, hydraulic, pneumatic, and mechanical components to complete various prescribed actions. In addition, some switch signals are transmitted to the numerical control device for processing through the auxiliary control system.

(5) Machine Tool Body

The machine tool body is the main part of the CNC machine tool, consisting of the foundation components of the machine tool (such as the bed and base) and various moving parts (such as the worktable, saddle, spindle, etc.). It is the mechanical part that completes various cutting processes and is an improvement based on conventional machine tools. It has the following characteristics:

CNC machine tools adopt high-performance spindles and servo drive systems, as well as mechanical transmission devices.

The mechanical structure of the CNC machine tool has high rigidity, damping precision, and wear resistance.

More efficient transmission components such as ball screw pairs and linear rolling guides are used.

Compared with traditional manual machine tools, CNC machine tools have undergone many changes in external appearance, overall layout, component structure of transmission and tool systems, and operating mechanisms. The purpose of these changes is to meet the requirements of CNC machine tools and fully utilize their characteristics. Therefore, it is necessary to establish new concepts for the design of CNC machine tools.

Compared with conventional machine tools, the difference in the working principle of CNC machine tools lies in the fact that they are processed according to instructions given in digital form. Typically, it requires the following steps:

(1) Based on the pattern and technical conditions on the part drawing, write the machining program for the workpiece and record it on the control medium or carrier;

(2) Input the program on the program carrier into the computer numerical control device through the input device;

(3) The computer numerical control device processes the input program through calculation and sends instruction signals to the servo system and auxiliary control device of each coordinate through the output device;

(4) The servo system amplifies the received instruction signals, drives the moving parts of the machine tool to move, and the auxiliary control device controls the operation of the spindle motor according to the instruction signals;

(5) The tool and workpiece are driven to move relative to each other through the mechanical components of the machine tool to produce a workpiece that meets the requirements of the pattern;

(6) The position detection feedback system detects the motion of the machine tool and feeds back the signal to the numerical control device to reduce machining errors.

Of course, for open-loop machine tools, there is no detection and feedback system.

Compared with conventional machine tools, CNC machine tools are highly efficient and automated electromechanical integrated machine tools that have the following processing characteristics:

(1) Wide adaptability and high flexibility:

CNC machine tools can be reprogrammed and input to process different objects. In some cases, only part of the program needs to be modified or special instructions utilized (such as using the zoom function instruction to process parts of the same shape but different sizes). This provides great convenience for single-piece, small-batch, multi-variety production, product transformation, and new product trial production, greatly shortening the production preparation and trial production cycle.

(2) High machining accuracy and stable quality:

Due to the use of a digital servo system, the CNC device generates a corresponding displacement amount (called pulse equivalent) of the machine tool for every output pulse, which can reach 0.1~1μm. The transmission screw of the machine tool adopts intermittent compensation, and the pitch error and transmission error can be controlled by a closed-loop system, so the CNC machine tool can achieve high machining accuracy.

For example, in precision machining centers, the positioning accuracy is generally up to an error of (0.005~0.008)mm per 300mm length, and the repeatability accuracy can reach 0.001mm. Additionally, the CNC machine tool has good structural rigidity and thermal stability, ensuring manufacturing accuracy. Its automatic processing method avoids human operation errors, ensures stable machining quality, and has a high pass rate. The CNC machine tool can achieve multi-axis linkage and can process complex surfaces that are difficult or impossible to process on conventional machine tools.

(3) High productivity:

The CNC machine tool can select the most favorable processing parameters to realize continuous processing of multiple processes. It can also achieve multi-machine supervision. Due to the adoption of acceleration and deceleration measures, the moving parts of the machine tool can quickly move and position, greatly saving the idle time during the processing process.

(4) Good economic efficiency:

Although the equipment cost of CNC machine tools (including depreciation costs, maintenance costs, power consumption costs, etc.) per part is relatively high, their high production efficiency saves auxiliary time (such as wire drawing, machine adjustment, processing inspection, etc.) and reduces direct production costs for single-piece and small-batch production. The stable machining accuracy of CNC machine tools reduces the scrap rate and further reduces production costs.

The performance characteristics of CNC machine tools determine their application scope. For CNC machining, the objects to be machined can be roughly divided into three categories according to their suitability.

(1) The most suitable category:

Parts with high machining accuracy requirements, complex shapes and structures, especially those with complex curves, curved surface contours, or parts with non-smooth inner cavities. These parts are difficult to process on conventional machine tools, and it is difficult to detect and guarantee quality. Parts that require milling, drilling, hobbing, slotting or tapping in one clamping.

(2) Relatively suitable category:

Parts that are expensive, difficult to obtain, and not allowed to be scrapped. When machining these parts on conventional machine tools, there are certain difficulties and they are easily affected by various factors such as the adjustment of the machine tool, the mental state of the operator, and the working conditions, which may result in defective or scrapped products.

Therefore, CNC machine tools can be chosen for reliable machining. They are used for parts that have low production efficiency and high labor intensity when processed on general-purpose machine tools, and for parts that require good consistency in size comparison or performance testing, and for parts produced in small batches of multiple varieties and specifications.

(3) Not suitable category:

Parts that require rough reference positioning using blanks for processing or require manual adjustment for positioning. Parts with unstable machining allowances when there is no online detection system on the CNC machine tool that can automatically detect and adjust the position coordinate of the part. Parts that require specific process equipment or are processed based on samples or prototypes, and parts that require mass production.

As the performance, functionality, and cost of CNC machine tools continue to improve, along with the continuous improvement and upgrading of CNC machining tools and auxiliary tools, the use of CNC machine tools for mass production is gradually increasing. Therefore, suitability is relative and will change with technological development.

From the perspective of the technological level of CNC machine tools, high precision, high speed, high flexibility, multifunctionality, and high automation are important development trends of CNC machine tools. For a single machine, not only is it required to improve its flexibility and automation level, but also it is necessary to have the adaptability of higher-level flexible manufacturing systems and computer integrated systems.

The spindle speed of domestically produced CNC equipment in China has reached 10,000-40,000 r/min, and the feed speed has reached 30-60 m/min. The tool change time is less than 2.0 seconds, and the surface roughness Ra is less than 0.008 μm.

In terms of CNC systems, several well-known CNC device manufacturers in the world, such as FANUC in Japan, Siemens in Germany, and A-B in the United States, are currently developing towards serialization, modularization, high performance, and systematization.

Their CNC systems all use 16-bit and 32-bit microprocessors, standard buses, and software and hardware module structures. Memory capacity has expanded to more than 1 MB, machine tool resolution can reach 0.1μm, high-speed feed speed can reach 100 m/min, and up to 16 control axes can be used, using advanced electrical and mechanical technology.

In terms of drive systems, AC drive systems are developing rapidly. AC drives have evolved from analog to digital, and controllers mainly composed of operational amplifiers and other analog devices are being replaced by digital integrated components mainly composed of microprocessors, thereby overcoming weak points such as zero drift and temperature drift.

As the working machine, machine tools have provided manufacturing tools and methods for industrial revolution and modern industrial development over the years. In the future development of industry and human civilization progress, the support and promotion of CNC machine tools will still be indispensable.

Looking to the future, a new round of industrial revolution brings new challenges and opportunities for the development of CNC machine tools. The integration of advanced manufacturing technology with the new generation of information technology and artificial intelligence also provides technical support for the technological innovation, product replacement, and industrial upgrading of CNC machine tools.

CNC machine tools will move towards high performance, multifunctionality, customization, intelligence, and green technology, and embrace future quantum computing technology to provide more powerful, convenient, and effective manufacturing tools for the new industrial revolution and human civilization progress.