Have you ever wondered how cutting-edge technology achieves such precision? Fiber lasers, a marvel of modern engineering, utilize rare-earth doped glass fibers to generate highly efficient and versatile laser beams. In this article, you’ll discover the mechanics behind fiber lasers, explore their various types, and understand their numerous industrial applications. From high-power cutting to delicate marking, learn how fiber lasers are revolutionizing manufacturing processes and what makes them superior to traditional laser technologies. Dive in to uncover the future of laser technology.

A fiber laser refers to a laser that uses glass fibers doped with rare-earth elements as the gain medium.

It can be developed on the basis of fiber amplifiers: under the action of pump light, high power density is easily formed in the fiber, causing the “population inversion” of laser energy levels in the lasing material.

When an appropriate positive feedback loop (forming a resonant cavity) is added, laser oscillation output can be formed.

Based on the types of fiber materials, fiber lasers can be divided into:

(1) Crystal Fiber Lasers.

The working material is laser crystal fiber, including ruby single-crystal fiber lasers and Nd3+: YAG single-crystal fiber lasers, among others.

(2) Nonlinear Optical Fiber Lasers.

The main types include stimulated Raman scattering fiber lasers and stimulated Brillouin scattering fiber lasers.

(3) Rare-Earth-Doped Fiber Lasers.

The base material of the fiber is glass, and rare-earth element ions are doped into the fiber to activate it, thus creating a fiber laser.

(4) Plastic Fiber Lasers.

Laser dyes are doped into the core or cladding of plastic fibers to create fiber lasers.

As a representative of third-generation laser technology, fiber lasers have the following advantages:

The advent of double-clad fibers is undoubtedly a major breakthrough in the fiber field, making the fabrication of high-power fiber lasers and high-power optical amplifiers a reality.

Since E Snitzer first described cladding-pumped fiber lasers in 1988, cladding pumping technology has been widely applied to fiber lasers and fiber amplifiers, becoming the preferred method for producing high-power fiber lasers.

Cladding pumping technology consists of four layers:

①fiber core;

②inner cladding;

③outer cladding;

④protective layer.

The pump light is coupled to the inner cladding (which generally adopts an irregular structure, including elliptical, square, plum blossom, D-shape, hexagonal, etc.), the light is reflected back and forth between the inner and outer claddings (generally designed to be circular), and is absorbed by the single-mode fiber core after multiple crossings.

This structure does not require the pump light to be a single-mode laser and can pump the entire length of the fiber, so a high-power multimode laser diode array can be chosen as the pump source, indirectly coupling more than 70% of the pump energy into the fiber core, greatly improving the pumping efficiency.

The characteristics of cladding pumping technology determine the following outstanding performance of this type of laser:

(1) High power

A multimode pump diode module group can emit 100 watts of optical power, and parallel setting of multiple multimode pump diodes allows for the design of high-power output fiber lasers.

(2) No need for thermoelectric coolers

This high-power, broad-area multimode diode can operate at high temperatures, requiring only simple air cooling, which is low-cost.

(3) Wide pumping wavelength range

The active cladding fiber doped with erbium/ytterbium rare earth elements in high-power fiber lasers has a wide and flat lightwave absorption range (930-970nm), hence, the pump diodes do not require any type of wavelength stabilization device.

(4) High efficiency

The pump light crosses the single-mode fiber core multiple times, thus its utilization is high.

(5) High reliability

Multimode pump diodes are much more stable than single-mode pump diodes. Their geometrically wide area results in low optical power density and low current density through the active area, giving the pump diodes a reliable operating lifespan of over 1 million hours.

Currently, the technologies to achieve cladding-pumped fiber lasers can be divided into three main categories: linear cavity single-end pumping, linear cavity double-end pumping, and all-fiber ring cavity double-clad fiber lasers. Different types of double-clad fiber lasers can be expanded from these three basic types.

One document from OFC-2002 adopted a structure to achieve a new type of cladding-pumped fiber laser with an output power of 3.8W, a threshold of 1.7W, and a slope efficiency of up to 85%.

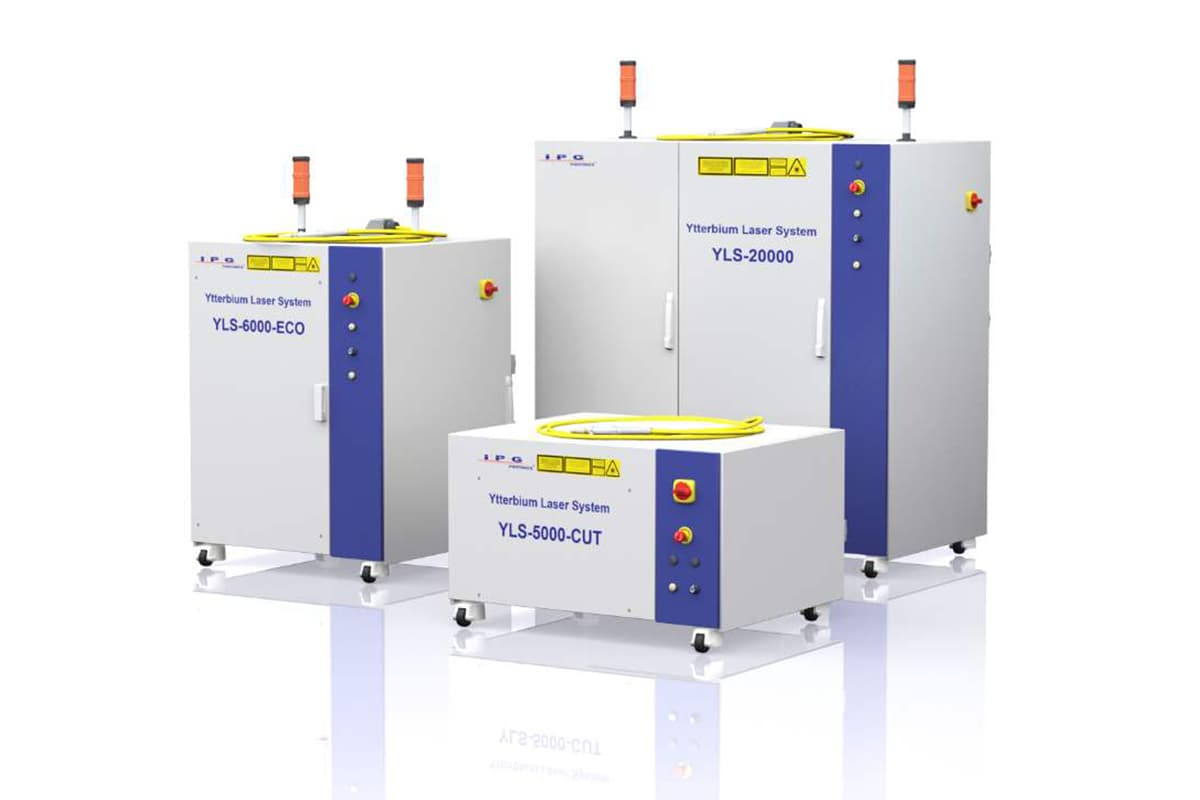

In terms of product technology, the American company IPG has emerged, having developed a 700W erbium-doped double-clad fiber laser and announced the launch of a 2000W fiber laser.

The pulse fiber laser, with its excellent beam quality, reliability, longest maintenance-free time, highest overall electro-optical conversion efficiency, pulse repetition frequency, smallest size, simplest and most flexible use without water cooling, and lowest operating cost, makes it the only choice for high-speed, high-precision laser marking.

A fiber laser marking system can consist of one or two 25W fiber lasers, one or two scanning heads for guiding light to the workpiece, and an industrial computer for controlling the scanning heads. This design is more than four times efficient than using a 50W laser split into two scanning heads.

Material processing with fiber lasers is a thermal treatment process based on parts of the material absorbing laser energy. Laser light with a wavelength of around 1um is easily absorbed by metals, plastics, and ceramic materials.

Fiber laser shaping or bending is a technology used to change the curvature of metal plates or hard ceramics.

Concentrated heating and rapid self-cutting lead to plastic deformation in the laser-heated area, permanently changing the curvature of the target workpiece.

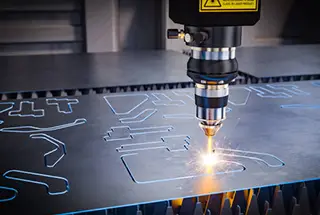

With the continuous increase in power, fiber lasers are being applied on a large scale in industrial cutting. For example, using a fast-chopping continuous fiber laser for micro-cutting stainless steel arterial tubes.

Due to its high beam quality, fiber lasers can achieve a very small focus diameter and, consequently, small kerf width, setting new standards in the medical device industry.

In addition, fiber lasers have an irreplaceable position in the field of optical communication because their wavelength covers two main communication windows at 1.3μm and 1.5μm.

The successful development of high-power double-clad fiber lasers has led to a rapid expansion in the market demand in the field of laser processing.

Specific scope and required performance of fiber lasers in the field of laser processing are as follows:

Furthermore, with the development of ultraviolet fiber Bragg grating writing and cladding pumping technology, wavelength conversion fiber lasers outputting in UV, blue, green, red, and near-infrared are widely used in data storage, color display, and medical fluorescence diagnosis as practical solid-state light sources.

Far-infrared wavelength output fiber lasers, due to their compact and flexible structure, tunable energy, and wavelength, are also applied in fields like laser medicine and bioengineering.

Early research on lasers focused mainly on short-pulse output and expanding the tunable wavelength range.

Today, the rapid development and progress of Dense Wavelength Division Multiplexing (DWDM) and Optical Time Division Multiplexing technologies are accelerating and stimulating the advancement of multi-wavelength fiber laser technology and supercontinuum fiber lasers.

Meanwhile, the emergence of multi-wavelength fiber lasers and supercontinuum fiber lasers provides an ideal solution for implementing low-cost Tb/s DWDM or OTDM transmission.

From the perspective of their technological implementation, the use of spontaneous emission amplified by EDFA, femtosecond pulse technology, and superluminescent diodes have all been reported.

As a representative of third-generation laser technology, fiber lasers possess unparalleled technical superiority over other lasers.

However, in the short term, we believe that fiber lasers will mainly focus on high-end applications. With the popularization of fiber lasers, the reduction in cost, and the increase in production capacity, they may eventually replace a large portion of high-power CO2 lasers and the vast majority of YAG lasers worldwide.