How does a device that combines multiple laser beams into one impact fiber laser performance? This article dives into fiber combiners, essential for maximizing laser output power and beam quality. Readers will learn about different types of fiber combiners, their roles, and how they are fabricated to ensure optimal performance in laser systems. Gain insights into this crucial technology and its applications in enhancing laser operations.

The optical fiber combiner is a type of optical fiber connection device that utilizes optical fiber precision fusion technology to maximize the coupling of optical energy from the transmitting optical fiber to the receiving optical fiber, while minimizing any impact on the system from its presence in the optical path.

The fiber combiner plays a crucial role in fiber laser systems. Its quality not only directly affects the power and beam quality of the fiber laser, but also provides a crucial guarantee for the safe and stable operation of the laser.

Based on their function, fiber combiners can be categorized into two types: power combiners and pump combiners.

Pump Combiner

Power combiner

Fiber combiners can also be classified based on their composition into two types: N×1 fiber combiners without a signal fiber and (N+1)×1 fiber combiners with a signal fiber.

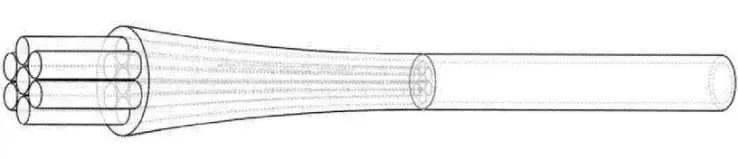

The (N+1)×1 fiber combiner differs from the N×1 combiner in that it includes a signal fiber at its center. During the manufacturing process, N optical fibers must be precisely and symmetrically arranged around the signal fiber, which serves as the input for the signal light.

Both the power combiner and pump combiner fall under the category of N×1 combiners. The specific function depends on the model of the N-channel input fibers.

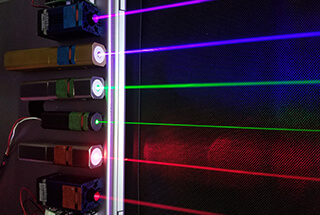

If the N-channel fibers are single-mode fibers or large mode field fibers, they can be directly connected to N lasers to increase the laser’s output power, resulting in a power combiner.

If the N-channel fibers are multimode fibers, they are connected to N pump sources to enhance the pump power of the laser, forming a pump combiner.

N × 1 optical fiber combiner

(N+1) × 1 beam combiners are specifically used for pump beams and are primarily found in optical fiber amplification systems.

The central fiber in the combiner is a single-mode fiber that transmits the signal light, while the N surrounding multimode fibers serve as the pump fibers for pump light transmission.

This type of combiner is commonly used in MOPA (Master Oscillator Power Amplifier) configurations.

(N+1) × 1 optical fiber combiner

The center fiber of the side-pump combiner serves as the signal fiber, and its core is a single-mode or quasi single-mode waveguide designed for laser transmission. The six peripheral fibers are used to transmit pump light.

Once these seven optical fibers are arranged in order, they are fused, drawn out, and joined with the output double-clad optical fiber.

End pumped combiner fiber combiner

The main difference between a side-pump combiner and an end-pump combiner is that the pump fiber in a side-pump combiner is attached to the cladding of the signal fiber without undergoing melting or tapering, while in an end-pump combiner the signal fiber is melted and tapered.

As a result, in principle, the signal transmission of a side-pump combiner is superior to that of an end-pump combiner.

Side pumped fiber combiner

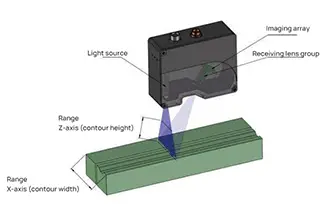

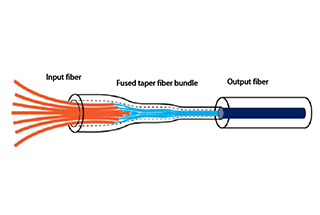

The power combiner has a basic structure comprised of three parts: input fiber, fused taper fiber bundle, and output fiber.

Basic structure of power combiner

To ensure that the fiber bundle fuses and tapers well with the output fiber, the cross-section of the fiber bundle must be circular, and the pump fibers must be arranged in a specific geometric pattern, typically in a regular hexagonal shape.

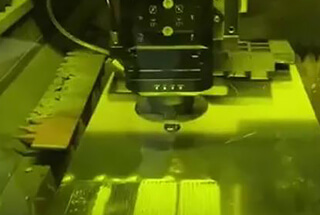

During the manufacturing process, the input fiber bundles are first assembled and then fused and tapered to form a fused taper fiber bundle. The taper waist of the fused taper fiber bundle is then cut and fused with the output fiber.

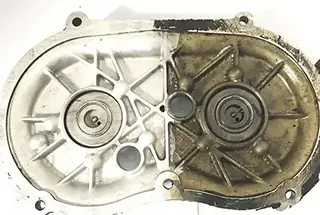

A robust packaging and heat dissipation structure is designed to ensure the stability and longevity of the beam combiner. Copper or aluminum, with high thermal conductivity, is commonly used as the packaging shell, and a water-cooling system may be integrated into the metal packaging as needed.

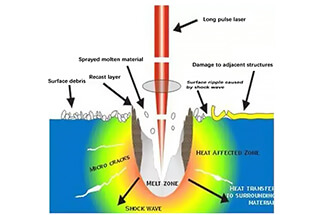

Fiber lasers connect fiber devices through welding. High-quality fiber fusion is crucial for achieving higher power. However, losses inevitably occur during the welding process, which accumulate light and heat over time, potentially leading to a deterioration in beam quality or damage to optical components.