Have you ever considered how industries achieve such precise surface enhancements on metals? Laser cladding might hold the key. This advanced technique melts coating materials onto substrates using laser beams, creating surfaces resistant to wear, corrosion, and heat. Through this article, discover how laser cladding revolutionizes the manufacturing and repair processes across various sectors, offering durability and cost-efficiency. Dive in to understand the intricacies of this technology and its transformative impact on modern engineering.

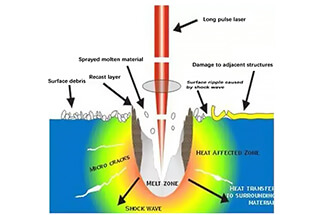

Laser cladding is a process that uses different filler methods to deposit selected coating materials onto the surface of a substrate.

The material is melted onto the surface of the substrate with a thin layer after being irradiated by a laser, and then rapidly solidified to form a surface coating with minimal dilution and metallurgical bonding with the substrate material.

This significantly improves the surface’s resistance to wear, corrosion, heat, oxidation, and enhances its electrical properties on the base material.

Laser cladding is a cost-effective technology that can create high-performance alloy surfaces on inexpensive metal substrates without altering the properties of the substrate. This reduces costs and conserves precious and rare metal materials.

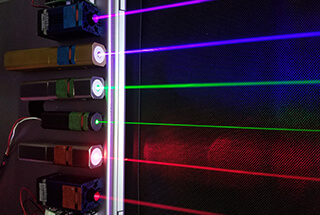

The lasers utilized in laser cladding are mainly CO2 lasers and solid-state lasers, such as disc lasers, fiber lasers, and diode lasers.

Laser cladding can be divided into two categories based on the different powder feeding process: powder preset method and synchronous powder feeding.

The two methods are similar, but synchronous powder feeding has advantages such as easy automation and control, high laser energy absorption, and no internal porosity. This is particularly beneficial for cladding metal ceramics, as it significantly improves the anti-cracking properties of the cladding layer and allows for a uniform distribution of the hard ceramic phase throughout the cladding layer.

1. Laser cladding has the following characteristics

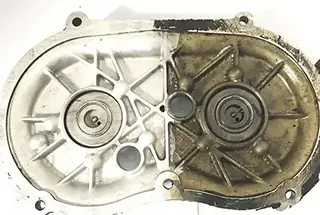

Laser cladding is highly suitable for the repair of commonly worn parts in oil fields due to its wear and tear resistance.

2. Differences and similarities between laser cladding and laser alloying

Both laser cladding and laser alloying use high-energy density laser beams to form an alloy cladding layer on the surface of a substrate, which is fused with the substrate and has a unique composition and properties.

The two processes are similar, but fundamentally different, with the following main differences:

(1) In laser cladding, the cladding material is completely melted with an extremely thin matrix melting layer, causing minimal impact on the composition of the cladding. In laser alloying, alloying elements are added to the surface of the base material in the molten composite layer, forming a new alloy layer based on the base material.

(2) Laser cladding does not rely on the molten metal of the substrate’s surface layer as a solvent, but instead melts a pre-configured alloy powder to create the subject alloy of the cladding layer. At the same time, the matrix alloy also has a thin layer of melting, leading to the formation of a metallurgical bond.

Laser cladding is a crucial foundation for the repair and remanufacture of failed parts under extreme conditions and the direct manufacture of metal parts. It has received significant attention from the scientific community and businesses worldwide for its ability to prepare new materials.

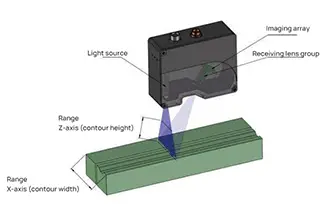

Evaluating the quality of laser cladding involves two main aspects: macroscopic and microscopic.

The macroscopic aspect examines the shape of the melt channel, surface unevenness, cracking, porosity, and dilution rate. Microscopically, it looks at the formation of a good organization and the provision of required properties.

In addition, the type and distribution of chemical elements in the surface cladding layer must be determined, attention must be paid to analyzing the transition layer for metallurgical bonding, and quality life testing should be performed if necessary.

Research efforts focus on the development of cladding equipment, the dynamics of the melt pool, the design of alloy composition, methods for crack formation, propagation, and control, and the bonding forces between the cladding layer and the substrate.

The main challenges facing the further application of laser deposition technology are:

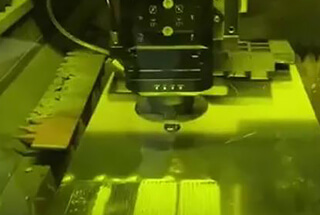

Laser cladding processing has a broad range of applications and fields, encompassing almost the entire machinery manufacturing industry.

Currently, laser cladding has been successfully applied to stainless steel, die steel, malleable cast iron, gray cast iron, copper alloys, titanium alloys, aluminum alloys, and special alloys such as cobalt-based, nickel-based, iron-based, and other self-fusing alloy powders and ceramic phases on the surface of laser cladding.

Iron-based alloy powders are suitable for parts that require local wear resistance and are prone to deformation.

Nickel-based alloy powders are ideal for components needing local abrasion resistance, heat resistance, and heat fatigue resistance.

Cobalt-based alloy powders are suitable for parts requiring local abrasion resistance, corrosion resistance, and thermal fatigue resistance.

Ceramic coatings have high strength at high temperatures, good thermal stability, and high chemical stability, making them suitable for parts that require wear resistance, corrosion resistance, high-temperature resistance, and oxidation resistance.

Some typical applications of laser cladding are:

Manufacturing and Remanufacturing of Mining Equipment and Components

Coal mining equipment experiences a lot of wear and tear due to its harsh working environment, leading to frequent breakdowns of parts. Laser cladding is used to manufacture and remanufacture these parts, including:

Roadheader cutting teeth

Hydraulic support column after cladding

Picks after laser cladding

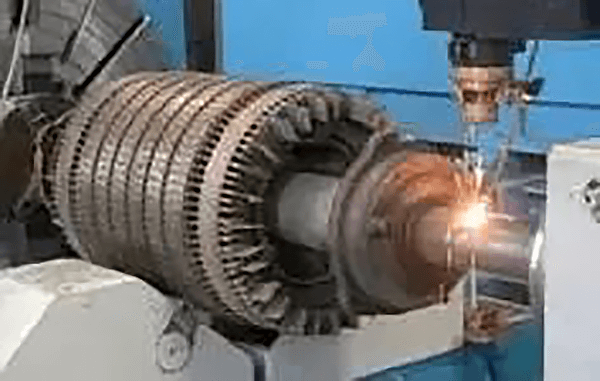

Manufacturing and Remanufacturing of Electrical Equipment and its Components

Electrical power equipment has a high distribution volume and is expected to operate continuously, making it vulnerable to damage to its components.

The steam turbine is the heart of thermal power generation, but its demanding working conditions, including high temperatures and heat, lead to regular wear and tear of key components, such as the main shaft and dynamic vanes, which must be repaired annually.

The gas turbine is also prone to damage due to its exposure to high temperatures of up to 1300℃.

Laser remanufacturing technology offers an effective solution to restore the performance of damaged equipment, and it is significantly more cost-effective, with a price tag that is only one-tenth of that of a new unit.

Laser cladding of motor rotor shaft

Steam turbine rotor repair

Repair of blade wear of powder exhaust fan

Manufacturing and Remanufacturing of Petrochemical Equipment and its Components

The petrochemical industry operates on a mass production model, which requires the use of machines that work continuously in harsh environments. Over time, the exposure to such conditions results in damage, wear and tear, and corrosion of equipment components.

Valves, pumps, impellers, rotor journals, discs, bushings, and shaft tiles are among the parts that are most susceptible to failure. These components are not only expensive but also complex in shape, making repairs difficult.

However, the advent of laser melting technology has eliminated these challenges, making it possible to effectively repair and manufacture these parts.

Laser cladding of hard ceramic coatings on oil drill pipes, drilling tools, etc.

Manufacturing and Remanufacturing of Railway Equipment and Components

The rapid growth of rail transportation and its corresponding socio-economic development has resulted in a high demand for new rail vehicles, as well as an increase in the number and performance requirements of key components.

One solution to this demand is the application of remanufacturing technology, which offers the potential to reuse wearable parts of vehicles.

The core technology behind remanufacturing is laser surface strengthening. This process involves the application of laser surface coating technology to repair and reinforce the surface of remanufactured parts.

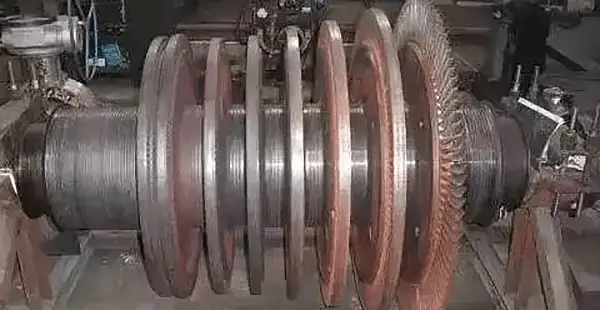

Remanufacturing of Key Components in Other Machinery Industries

The remanufacturing of key components is not limited to the railway industry, and is also applied in a variety of other machinery industries, including metallurgy, petrochemical, mining, chemical, aviation, automotive, shipping, machine tools, and more.

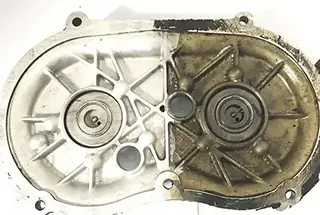

To repair and improve the performance of precision equipment, large equipment, and valuable parts that are susceptible to wear, erosion, and corrosion, the laser cladding process is utilized.

Laser cladding of worm-gear bars for gantry boring and milling machines

Highly wear-resistant steel continuous casting rolls with laser cladding