Imagine shaping metal with such precision that it transforms into complex, custom forms effortlessly. That’s the magic of press brake tooling, a vital process in sheet metal fabrication. In this article, you’ll discover how these tools work, the different types available, and the critical factors for selecting the right tooling for your needs. Whether you’re a novice or an expert in metalworking, understanding press brake tooling will elevate your skills and ensure flawless, efficient production.

Press brake tooling, widely used in the sheet metal fabrication industry, is a common tool for processing sheet metal.

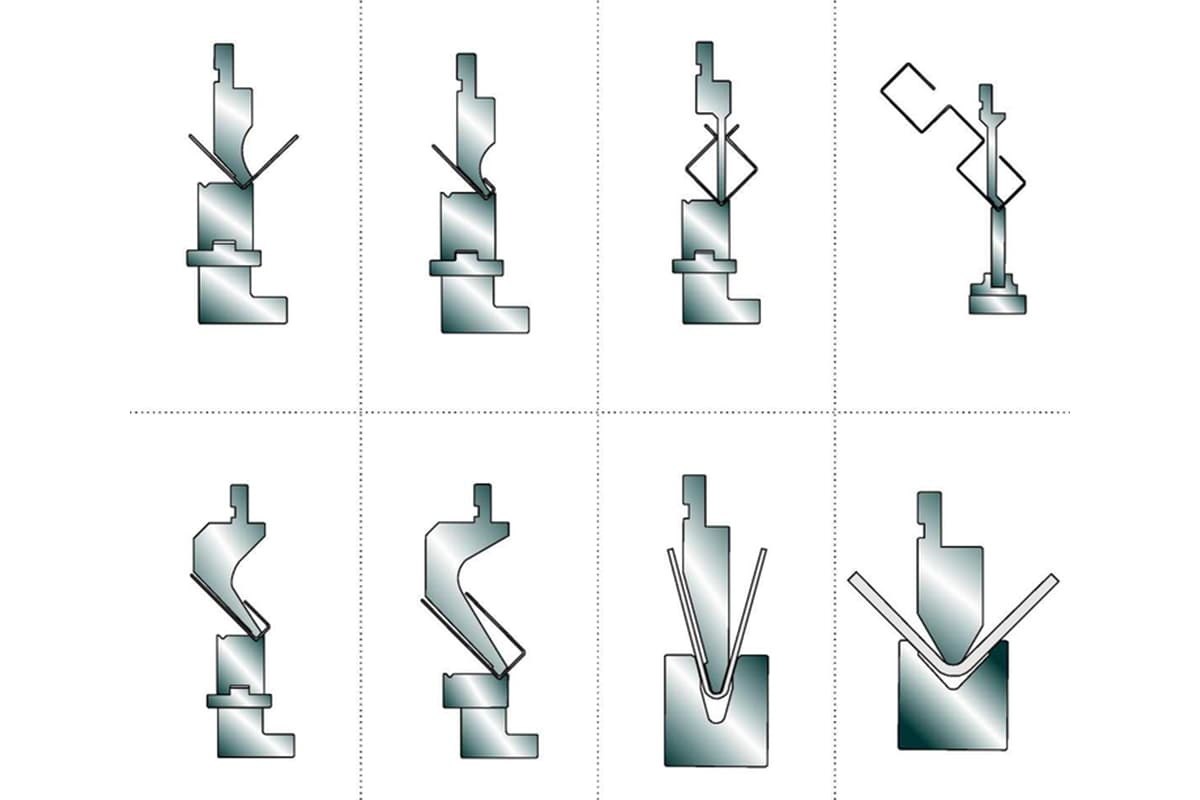

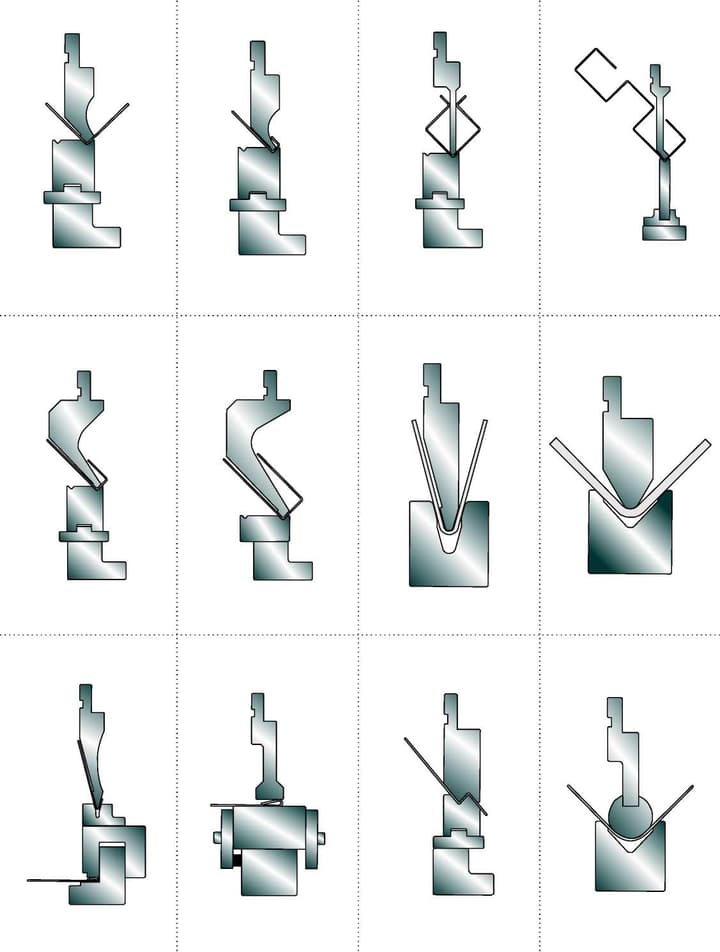

Press brake tools can mainly be divided into two categories: the upper tool (punch) and its accessories, and the lower tool (die) and its accessories.

The components of the upper tool include the upper clamp, the punch, the handle, and the tool head. The lower tool components consist of the die, die holder, seat, and clamps. These components can be combined interchangeably and are made from tooling materials.

In operation, the upper tool (punch) presses on the surface of the sheet, while the lower tool (die) constrains it, deforming the sheet into the desired shape. During this process, the sheet bends and deforms, with the inner material of the bent radius getting compressed and the outer material stretched.

Inevitably, the tooling material and the sheet will experience friction and compression against each other, leading to irreversible wear of the tooling.

The contact surface between the press brake tool material and the workpiece is often a fresh surface; the contact pressure is extremely high, sometimes exceeding the yield strength of the processed material.

The contact surface temperature can range from 200°C to 500°C and can peak at 800-1000°C. Tooling material wear typically results from a combination of mechanical wear, thermal deformation, and chemical effects.

Because of this, when choosing press brake tooling material, certain properties should be considered: hardness, heat resistance, and wear resistance.

Typically, T8-T12 carbon steel is used, with T10 being the most popular due to its balanced toughness and wear resistance.

After heat treatment, its hardness can exceed 60HRC. It’s cost-effective to produce, but has poor quenching and heat resistance (up to 250°C). This steel is frequently used for standard press brake tools. For superior tooling material, 42CrMo high-strength alloy structural steel is chosen.

42CrMo is an ultra-high-strength steel with excellent strength and toughness. After tempering, it boasts a high fatigue limit and multiple impact resistance and can operate below 500°C. Post heat treatment, its ideal hardness is around 45-48HRC.

Currently, most CNC press brake tools are made of 42CrMo material. An even better option is cold-work tool steel Cr12MoV. Enriched with a fair amount of chromium, molybdenum, and vanadium, it offers improved quenching and hardness.

After quenching, its overall mechanical properties outperform other steel types, making it suitable for large-section, complex, frequently used cold-punching molds. Tools made from it have high precision and longevity, though the material costs are substantially higher.

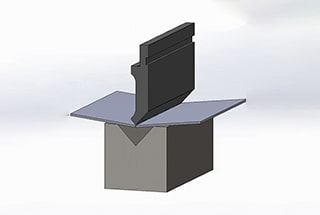

Press brake toolings are auxiliary tools used by press brake machines to shape sheets and process plate materials. These tools consist of various components, with different dies made up of different parts and shapes.

They primarily alter the physical state of the material being shaped, mainly metal sheets, through the pressure applied by the press brake machine. This alteration process helps achieve the desired shape for the material.

Press brake toolings can be structurally categorized into two main types: upper dies and lower dies.

In most cases, the upper die is the active one (moving), while the lower die remains stationary. However, in some press brake machines with different operational modes, this might be reversed, but the overall concept remains the same.

From a usability perspective, press brake machine dies can be classified into standard dies and special dies.

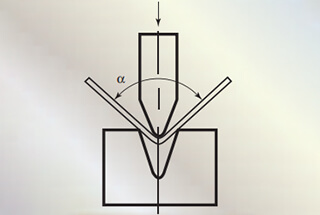

Standard upper dies usually have tip angles of around 30 degrees (actual angle 26-28 degrees), 60 degrees, and ranges between 78 to 88 degrees.

On the other hand, the groove angles for lower dies are roughly 30 degrees, 45 degrees, 60 degrees, and ranges from 80 to 90 degrees.

If we categorize upper dies based on shape, they can be divided into sharp blade dies, arc dies, bending blade dies, and forming dies.

Typically, sharp blade dies are commonly found with angles of 30 or 60 degrees, with occasional special angles like 45 or 55 degrees.

Arc dies are mainly designed based on the diameter and length of the arc. Bending blade dies are primarily used for “U” shaped parts or for clearance in multiple bends. The most complex are the forming dies. These can be monolithic or modular.

Generally, modular dies are designed, manufactured, and used as a set, both upper and lower. The manufacturing cost of monolithic forming dies is considerably higher, especially for larger sizes, and precision is harder to maintain. Modular dies have significant advantages for large and complex designs.

In terms of functionality, press brake dies can be categorized into single-function dies and multi-function dies.

Single-function dies are designed for one specific type of part, while multi-function dies can process various types. Some multi-function dies can be disassembled and reassembled, often referred to as composite dies, such as step dies and forming dies.

For lower dies, based on the number of grooves, they can be categorized into single V-dies, double V-dies, and multi V-dies. Single and double V-dies, as the names suggest, have one or two grooves respectively, commonly found in CNC press brake machines.

They offer higher precision due to their fixed reference, also known as concentric dies, and can be interchanged. Multi V-dies usually have multiple grooves of various sizes on all four sides, catering to bending different thicknesses of sheets.

With continuous societal advancements and increasing product demands, the requirements for bent products and their materials are also rising. Press brake toolings continue to evolve with the introduction of embedded lower dies, mark-free lower dies, and adjustable opening lower dies, all widely used across various industries.

A CNC press brake is a mechanical device designed for the processing of metal materials. By bending metals, it can achieve intricate shapes and angles. To attain different bending forms, the right die or tooling must be chosen.

Here, we’ll discuss the selection based on tooling materials, structure, and shape requirements.

Firstly, the material of the tooling plays a crucial role in the selection. Common tooling materials include high-speed steel, alloy tool steel, and tungsten carbide. Each material has its unique characteristics and applications.

For instance, high-speed steel tools boast high hardness and wear resistance, ideal for processing small batches of metal. Alloy tool steel is suitable for medium batches due to its commendable hardness and wear resistance. In contrast, tungsten carbide, with its extreme hardness and wear resistance, is perfect for large-scale operations.

Therefore, one should choose tooling material based on production demands and batch size.

Secondly, the structure of the tooling is another vital factor to consider. Common CNC press brake tool structures include single-V dies, multi-V dies, and U-dies. Single-V dies, with their smaller contact area, are used for smaller angles and bending radii, fitting for thinner metals.

Multi-V dies cater to broader angles and radii with a more extensive contact area, making them suitable for thicker materials. U-dies, designed for more complex shapes with larger bending radii and a sizable contact area, are best for very thick materials.

Hence, when choosing tool structure, consider the processing requirements and metal thickness.

Moreover, the shape requirement of the tooling is essential. Different tool shapes correspond to diverse bending forms. Common shapes include right-angle dies and radius dies. Right-angle dies are precise in processing right-angle bends, while radius dies facilitate various curved forms. So, the tool’s shape should be selected based on the processing requirements and metal shapes.

Additionally, consider the tooling’s precision and wear resistance. Precision refers to dimensional accuracy and shape during processing. Higher precision leads to better quality and exactness.

Wear resistance signifies the tool’s durability and its ability to withstand wear over prolonged use. Superior wear resistance can extend tool life and reduce production costs. In tool selection, weigh both the precision and wear resistance needs.

In conclusion, the appropriate tooling selection requires considering material, structure, and shape requirements.

One must align with production needs and batch sizes when choosing materials, and align tool structure and shape with processing requirements and metal thickness. Additionally, precision and wear resistance are vital. By considering these factors holistically, one can select the right tooling to achieve superior processing quality and efficiency.

Damage to CNC press brake tooling refers to cracks, breaks, and deformations. To address this issue, it’s essential to consider the design, manufacturing process, and usage of the tooling.

Firstly, it’s important to verify if the material used for manufacturing the tooling is appropriate and if the corresponding heat treatment process is reasonable.

Typically, the heat treatment process of the tooling material greatly influences its durability.

If the hardening temperature of the tool is too high, or the hardening method and duration are inappropriate, along with improper tempering frequency, temperature, and elbow gap selection, the tooling might get damaged after entering the bending production.

If the size or depth of the clearance hole is insufficient, it might lead to blockage, resulting in damage. An under-designed spring force or unevenly matched height sets can cause spring breakage, tilt, overlapping strikes, and damage to parts.

Improper fixation of the punch or inadequate screw strength may cause the punch to drop or break.

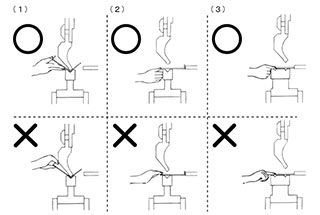

During the use of the press brake tooling, errors in part positioning, orientation, or improper bolt fastening can occur. If the working height is adjusted too low, or there’s insufficient lubrication to the guide columns, or there are malfunctions in the feeding equipment and anomalies in the press machine, it can lead to tool damage.

Continuation of production without addressing issues like foreign objects entering the tooling, overlapping parts, or waste obstruction can easily damage the tooling’s clearance plate, punch, lower template, and guide columns.

During the bending process, if the press brake tooling doesn’t close flexibly or even jams, production must be halted immediately to identify the cause and rectify the issue. Otherwise, it could escalate the problem, leading to tool damage.

The primary reasons for tool jamming include poor tool guidance, tilting, or the presence of foreign objects preventing flat alignment of the templates; inadequate tool strength or uneven force application causing tool deformation.

For instance, if the tool seat or template’s hardness or thickness is too low, it can easily deform upon impact; misalignment during tool installation, exceeding tolerances in upper and lower tool positioning or low precision in the press machine, can cause interference.

Insufficient punch strength or proximity between large and small punches can cause imbalanced lateral forces on the tool. In such cases, it’s advisable to increase punch strength and enhance the guidance protection of the discharge plate.

The cost of tooling for bending production is high, typically accounting for 1/5 to 1/4 of the total cost of the manufactured parts. This is not only because of the high manufacturing complexity and cost of the tooling but also due to the high repair and blade sharpening maintenance costs after it’s put into production.

The original manufacturing price of the tooling only accounts for about 40% of the total tooling costs. Therefore, timely tool repairs and preventative maintenance can significantly reduce the tooling expenses for bending production.