Is your fiber laser cutting machine losing power and impacting productivity? This article reveals the hidden reasons behind the power drop, from focus position and nozzle distance to auxiliary gas and cutting speed. By understanding these factors, you can troubleshoot and maintain optimal performance, ensuring precise and efficient cuts every time. Read on to discover practical tips and solutions to keep your laser cutting machine running at its best.

Losses are inevitable with any machine, including metal laser cutting machines. Over time, users may experience decreased cutting speed and accuracy.

It is a common misconception that a decrease in laser power is the sole cause of these problems. However, there are various factors that can contribute to the decline of laser cutting machine power, not just issues with the laser itself.

The following is an analysis of the reasons for the power decline of fiber laser cutting machines.

The focus position plays a crucial role in determining the precision of laser cutting, particularly with regards to the focus spot diameter.

To achieve a precise cut, it is ideal to have a small focus spot diameter. This creates a narrow slit, which is crucial for achieving high precision cuts.

The size of the focus spot diameter is directly proportional to the focal depth of the focusing lens. The smaller the focal depth of the lens, the smaller the focus spot diameter will be.

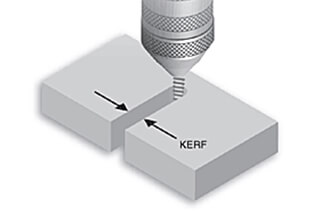

The distance between the nozzle and the workpiece also contributes to the power reduction of a fiber laser cutting machine.

If the distance is too far, it will result in the wastage of kinetic energy. On the other hand, if the distance is too close, it will negatively impact the dispersion ability of the cutting products.

The optimal distance between the nozzle and the workpiece is 0.8mm. To accommodate for workpieces with an uneven surface, the fiber laser cutting machine can be adjusted accordingly during operation.

It is important to maintain consistency in the height of the nozzle and workpiece during the cutting process.

The cutting speed has a significant impact on the power of fiber laser cutting equipment.

The power of the fiber laser cutting machine is directly proportional to the cutting speed.

Additionally, the quality of the cut is related to the quality of the laser beam and the characteristics of the laser beam focusing system. The size of the focused laser beam has a significant effect on the quality of the laser cutting.

The size and pressure of the auxiliary gas also have an impact on the power of the fiber laser cutting machine.

It is preferable to use compressed air or inert gas as the auxiliary gas.

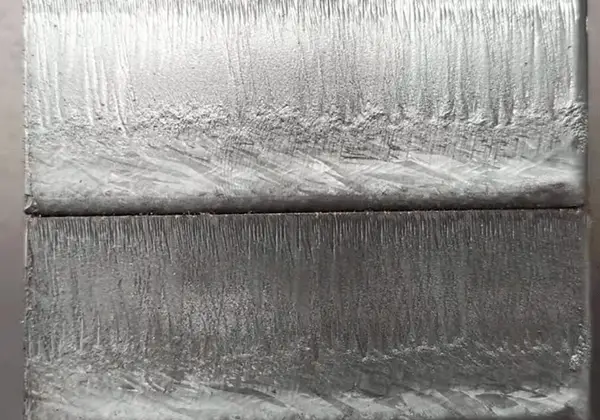

When processing thicker materials or cutting at a slower speed, it is necessary to reduce the air pressure appropriately. Cutting with lower air pressure can prevent the formation of frost on the cutting edge.

If all other factors are ruled out, a decrease in laser power may be considered.

Like any other equipment, the components of a metal laser cutting machine will inevitably experience wear and tear over time.

The laser is the core and most crucial component of the metal laser cutting machine. Its power will naturally decrease with prolonged use.

In addition to the previously mentioned factors, the performance, size, and thickness of the materials being processed can also affect the power reduction of the fiber laser cutting machine.