Why is heat treatment essential in mechanical processing? This crucial process, which includes methods like annealing, normalizing, quenching, and tempering, transforms metal properties to enhance durability, hardness, and stress resistance. Imagine crafting a car engine without ensuring its parts can withstand high temperatures and wear—failure is inevitable. In this article, you’ll learn how heat treatment optimizes machining performance, reduces material defects, and prepares components for their demanding roles, ensuring they meet exacting industrial standards. Get ready to uncover the science behind making metal work flawlessly in engineering applications.

This is a good question that often confuses newcomers and experienced professionals alike. Today, I will provide a detailed explanation of the heat treatment requirements for machining.

These requirements are actually a crucial aspect of the design process, and any mechanical structural design engineer must possess a solid understanding of them. Without this awareness, one cannot be considered a qualified design engineer, at least not a comprehensive one.

Understanding the heat treatment design requirements for a part is based on the perception of changes in material use and processing, and is a fundamental part of a systematic knowledge structure.

To begin, we must first understand the various methods involved in heat treatment for parts machining. We will focus on the most frequent and important methods in the machining process for our analysis.

In the machining process, we use four main heat treatment methods: annealing, normalizing, quenching, and tempering.

Let’s analyze each one individually.

01 Annealing

Definition of annealing treatment:

A metal heat treatment process involves heating a metal part to a specific high temperature for a certain period and subsequently allowing it to cool naturally.

Its main function:

02 Normalizing treatment

The definition of normalizing treatment:

Heat the metal parts to a specific high temperature for a designated period of time, and subsequently cool them using methods such as water spraying, mist spraying, blowing, etc.

This process differs from annealing treatment as it involves a faster cooling rate, resulting in a finer material structure and improved mechanical properties.

Its main function:

03 Quenching treatment

Definition of quenching treatment:

The metal part needs to be heated to a temperature above the critical temperature, Ac3 or Ac1, for a specific period of time to achieve complete or partial austenitization.

Subsequently, the martensite transformation can be initiated by quickly cooling the metal part to a temperature below the Ms, using a cooling rate greater than the critical cooling rate.

Its main function:

04 Tempering treatment

Definition of tempering treatment:

This refers to a heat treatment method in which quenched or normalized steel is immersed in a temperature lower than the critical temperature for a certain period of time, and then cooled down at a specific rate to increase the material’s toughness.

Its main function:

Attention! The following key knowledge is about annealing, normalizing, and tempering:

Annealing and normalizing are interchangeable and can be used instead of each other, particularly when the obtained part’s hardness after treatment is not high, without affecting its processing performance. However, it is advisable to prioritize normalizing treatment because it has a shorter processing cycle and lower cost.

Tempering is generally used in conjunction with quenching or normalizing. Its purpose is to clean up the residual stress left in the parts after quenching and normalizing. These processes increase the parts’ hardness, which may result in high residual stress. In the quenching process, the parts can become brittle, making tempering necessary to correct the issue and better meet the usage requirements.

As a mechanical design engineer, when designing parts that require heat treatment, we must fulfill the following requirements:

Our heat treatment requirements for most parts are based on the three major aspects mentioned above. Therefore, to meet your requirements, you only need to utilize the following four heat treatment methods.

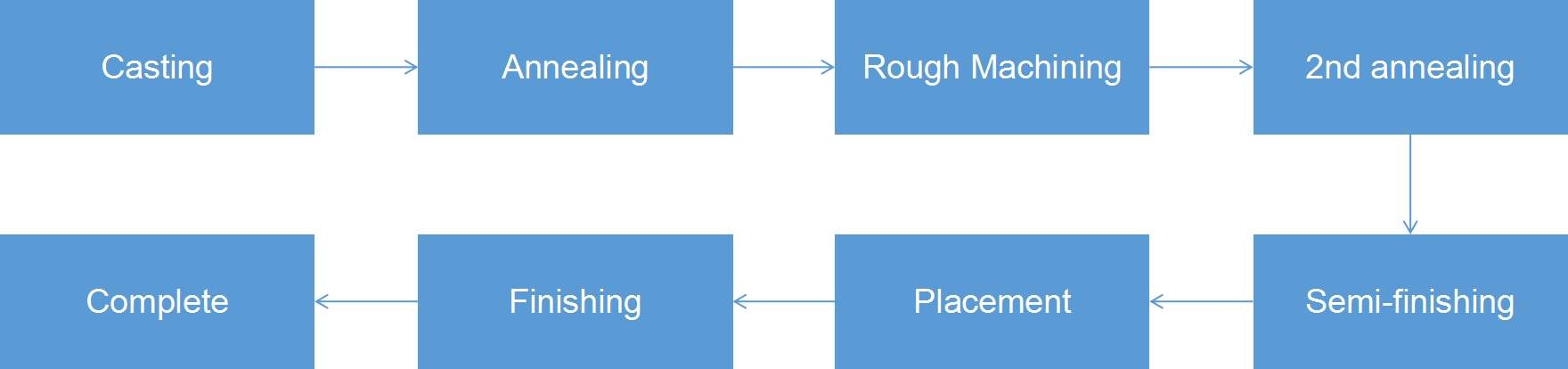

Let’s consider an example of a bed designed for a vertical machining center. We selected HT300 grey cast iron as the material. The process flow for the manufacturing process is roughly as follows:

A. After getting the foundry blank, the first thing we need to do is to anneal.

The purpose of annealing is to eliminate residual internal stress in castings and improve the cutting performance of the parts. However, some manufacturers choose not to anneal their products in order to save costs. Instead, they may extend the cooling time of the casting to partially remove the internal stress. While this approach may be opportunistic, it does not follow the formal method. According to the proper procedure, the blank of the cast part must be annealed.

B. Next is the rough machining process of the part.

The roughing process for parts doesn’t require strict adherence to size specifications, therefore, the factory utilizes large-sized cutters.

During the cutting process, the impact of the milling cutter on the parts creates a certain level of vibration processing, which is also a stress-release process. However, it can also be a process of re-stressing, and as a result, a second annealing treatment is carried out on the part.

C. Secondary annealing treatment.

The objective of this treatment remains the same as the previous one, which is to stabilize the material structure, enhance cutting performance, and eliminate internal stress in the part.

It is crucial to ensure that the dimensional and shape tolerances of the parts remain constant after processing, instead of altering over time. However, in reality, the dimensional accuracy and shape tolerance of the processed parts often change, leading to poor performance of high-precision machine tools in developing countries. This instability is a critical reason behind this problem.

In the 1970s and 1980s, the material stability of the basic machine parts was relatively better as they underwent regular secondary annealing treatment, coupled with natural aging treatment. During natural aging treatment, castings were left in an open space for over six months. At that time, due to limited production capacity, material stability could be guaranteed to the maximum extent, whereas now, this approach seems outdated.

Producing high-quality products is often associated with increased costs.

D. Semi-finishing parts.

Since the semi-finishing stage of a part involves minimal cutting, excessive machining stress is typically not generated during the process. However, if the part requires high dimensional accuracy and strict geometrical tolerance, we strongly recommend allowing it to rest before finishing.

This resting period allows the part to release some of its stress naturally, ensuring the final finished product is stable. Unfortunately, many people overlook this critical step, and the machining process is often streamlined for efficiency at the cost of quality.

E. Finishing process of parts.

After a certain period of time, the material of the component has become relatively stable.

During the finishing stage, it is crucial to assess the operator’s skills.

In many cases, the precision of finishing is not solely dependent on the accuracy of the machine tool, but it may also be influenced by the clamping method.

Especially for parts that lack strength and rigidity, more attention should be paid to clamping.

Avoid using excessive force to compress the workpiece.

If the workpiece becomes deformed during machining, it will return to its original state as soon as the clamp is released, resulting in a change in processing accuracy.

Therefore, during the finishing process, the clamping force is particularly important and is also the secret of many experts.

The above is a sharing of the application of heat treatment processes involved in machining a part. There are many similar processes, such as quenching and carbonitriding. Accumulating such experiences is crucial for a qualified mechanical design engineer.

Despite the increasing performance of numerical control equipment and higher automation, traditional mechanical knowledge remains essential. This knowledge serves as the foundation for making good use of advanced technologies. The path to technological progress is gradual and requires step-by-step implementation.