Imagine a world where your machinery grinds to a halt, not from lack of use, but from too much lubrication. This article explores the delicate balance of lubricating bearings. Proper lubrication reduces friction and wear, while too much can increase friction, heat, and even cause leaks. Understanding this balance is key to maintaining efficient and long-lasting machinery. Learn how to optimize lubrication to enhance performance and avoid common pitfalls.

Many engineers often believe that the more lubrication added to a bearing, the better, given the common understanding of its importance. This practice is prevalent in many engineering applications.

It’s easy to comprehend the significant impact that insufficient lubrication can have on bearing operations. However, people seldom contemplate the effects of excessive lubrication. Is more lubrication always beneficial for bearings?

To address these questions, let’s discuss the functions of lubrication.

Firstly, we must understand why we add lubrication to bearings.

Reducing Friction and Wear

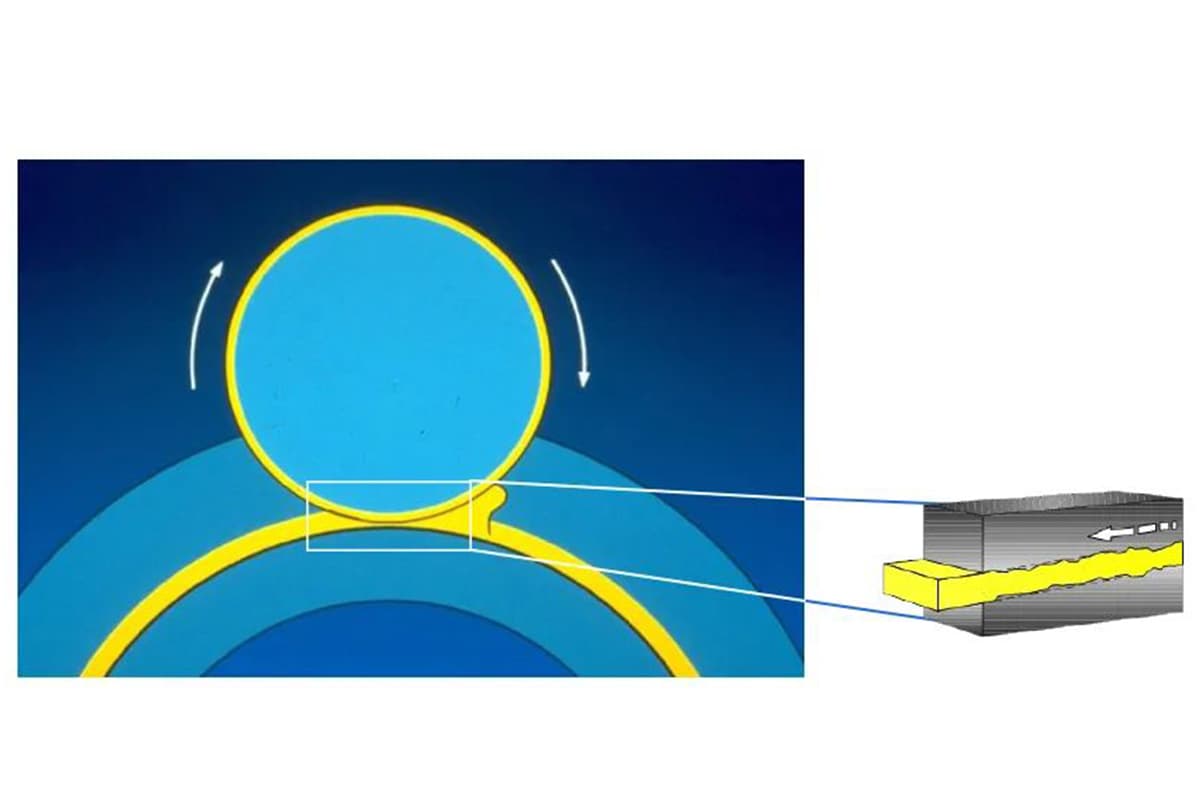

A bearing is a mechanical part with relative motion between its internal components during operation. These moving parts are typically made of steel, and the lubricant is filled into the gaps among these parts (rolling elements, inner ring, outer ring, cage). Once operational, a lubricating oil film forms on the component surfaces.

This film reduces or eliminates the direct hard contact between metals, thereby reducing friction among the bearing’s internal parts. This not only prevents wear but also reduces the heat generated.

Cooling and Heat Dissipation

Whether using grease or oil for lubrication, the heat generated by rolling or sliding friction is dissipated through conduction, which serves to cool and lower the temperature.

Rust and Corrosion Prevention

The lubricant used in rolling bearings also has excellent anti-rust properties, which can prevent the bearings from rusting.

From the aforementioned features, we understand that lubrication is an indispensable part of the bearing operation. Moreover, in the calculation of bearing life, lubrication is a crucial factor in the equation.

Having understood the function of bearing lubrication, we pay significant attention to the addition of grease, often preferring to “over-add” than to risk “under-adding. This is because, based on practical experience, engineers feel that adding a bit more offers an extra layer of assurance, which can’t be wrong.

However, the reality is often not the case.

We can easily understand the condition of insufficient lubrication, where the metallic components of the bearings are not fully segregated. There’s still metal-to-metal contact, leading to wear that raises the temperature and may even generate wear debris within the bearings.

But what about excessive lubrication? What impacts does that have?

When bearings operate, a lot of friction is generated internally, including 1) rolling friction, and 2) sliding friction. According to modern bearing friction theory, we should also consider 3) seal friction, and 4) grease friction.

“Wait, does grease cause friction too?”

Yes, that’s indeed the case.

In rolling bearings, friction includes the four aspects mentioned above, represented by the following formula:

M=Mn+Msf+Mseal+Mdrag

Where:

When grease is added to the interior of the bearings, excessive grease can lead to more stirring of the lubricant. This in turn increases the grease friction torque, resulting in an overall increase in friction.

The outcome is not only a decrease in the cooling performance of the grease but also an increase in the overall operating temperature. Additionally, adding too much grease can exert extra pressure on the seals, causing leakage incidents.

Thus, with the advancement of modern bearing manufacturing performance, our concern is not insufficient lubrication, but rather excessive lubrication. It is vital to maintain an appropriate amount of grease, including initial lubrication and re-lubrication.