How do polishing machines achieve that perfect finish on metal surfaces? In this article, we explore the intricate mechanics behind these essential tools. From the components involved to the dual-stage polishing process, you’ll learn how these machines ensure both efficiency and precision. Discover practical insights into how polishing machines work, their applications, and tips for achieving optimal results in metalworking. Whether you’re a seasoned professional or new to the field, this guide provides valuable information to enhance your polishing techniques.

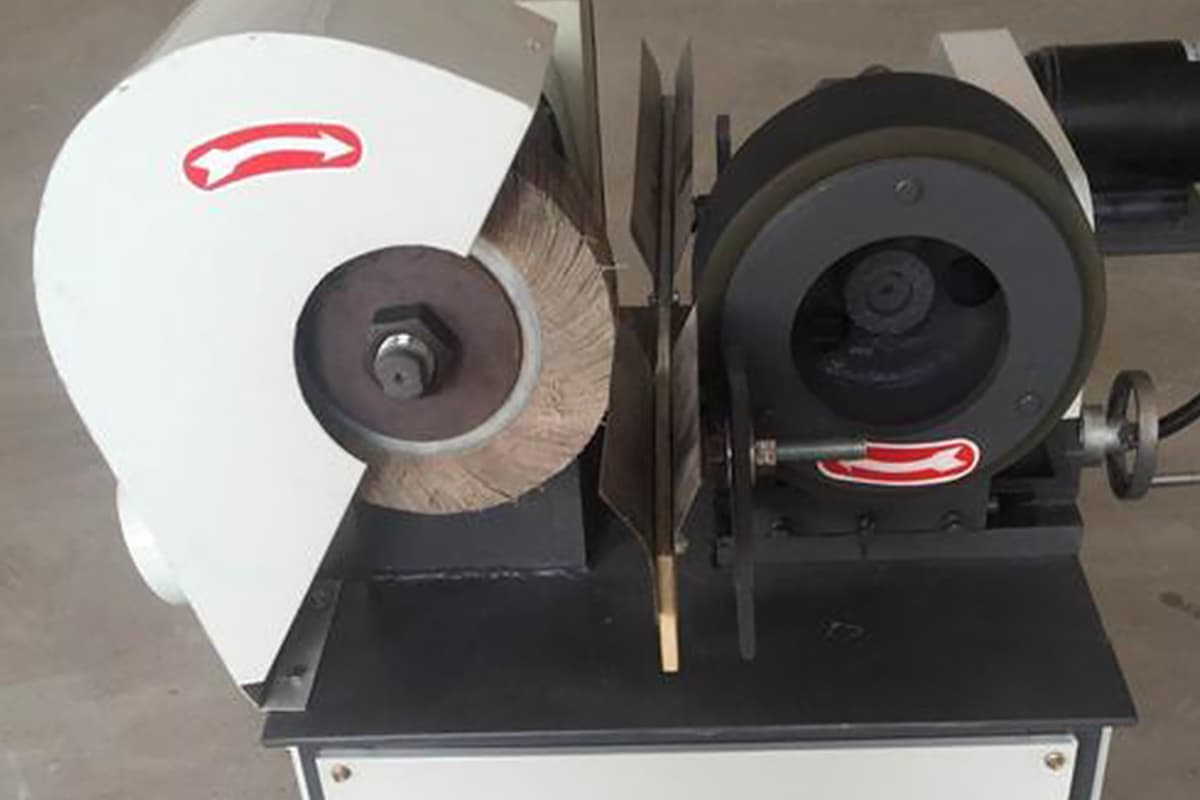

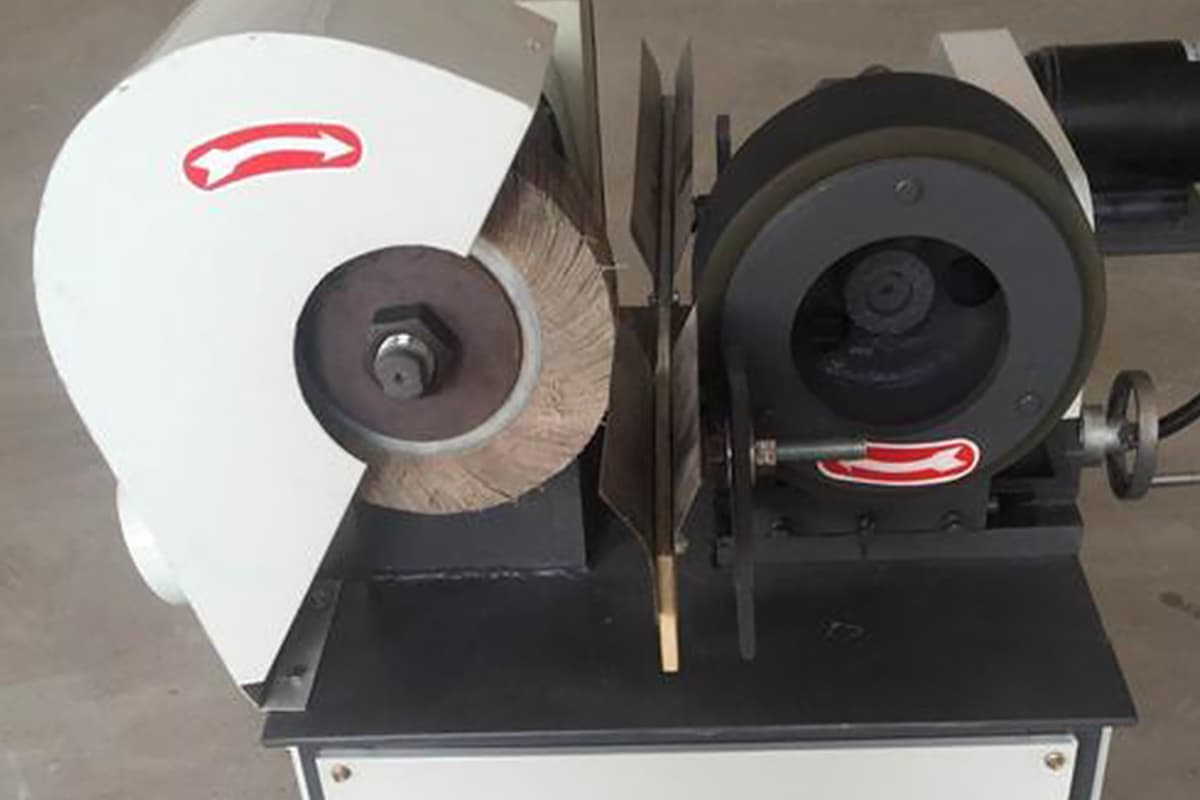

A polishing machine is an electric tool composed of fundamental components such as a base, polishing disc, polishing fabric, polishing cover, and lid.

The motor is fixed on the base, and the taper sleeve used to secure the polishing disc is connected to the motor shaft via screws.

The polishing fabric is secured onto the polishing disc through a ring, and when the motor is started by switching on the power via the base, the sample can be polished on the rotating disc by applying pressure manually.

The polishing fluid added during the process can flow into a square tray placed next to the machine through a drainage pipe in a plastic tray fixed on the base.

The polishing cover and lid prevent dust and other debris from falling onto the polishing fabric when the machine is not in use, thereby maintaining its efficiency.

The key to operating the polishing machine is to achieve the highest possible polishing rate to quickly remove the damage layer produced during grinding.

At the same time, the polishing damage layer should not disrupt the final observed structure, meaning it should not create false structures.

The former requires the use of coarser abrasives to ensure a higher polishing rate to remove the grinding damage layer, but the polishing damage layer will also be deeper.

The latter requires the finest materials to make the polishing damage layer shallower, but the polishing rate will be lower.

The best solution to this contradiction is to divide the polishing into two stages. The purpose of rough polishing is to remove the grinding damage layer, this stage should have the maximum polishing rate, and the surface damage formed by rough polishing is a secondary consideration, but it should also be as small as possible.

The second is fine polishing (or final polishing), the purpose of which is to remove the surface damage caused by rough polishing, reducing the polishing damage to a minimum.

When the polishing machine polishes, the grinding surface of the sample should be absolutely parallel with the polishing disc and evenly and lightly pressed on it, taking care to prevent the sample from flying out and creating new scratches due to excessive pressure.

At the same time, the sample should rotate and move back and forth along the radius of the turntable to avoid rapid local wear of the polishing fabric.

Micro powder suspensions should be continuously added during the polishing process to keep the polishing fabric at a certain moisture level.

Too much moisture can reduce the effect of the polishing scratches, causing the hard phase in the sample to protrude and non-metallic inclusions in the steel and graphite phase in cast iron to produce “tail dragging” phenomena.

If the humidity is too low, the sample will heat up due to friction, the lubrication effect will decrease, the grinding surface will lose its gloss, and even appear black spots, and light alloys will damage the surface.

To achieve the purpose of rough polishing, the turntable speed should be relatively low, preferably not exceeding 600r/min; the polishing time should be longer than the time required to remove the scratches, because the deformation layer also needs to be removed.

After rough polishing, the grinding surface is smooth but dull, and under a microscope, there are uniform and fine scratches that need to be eliminated by fine polishing.

During the fine polishing stage, the turntable’s speed can be appropriately increased, and the polishing time should be sufficient to remove the layer of damage caused by the coarse polishing.

After fine polishing, the grinding surface shines like a mirror. No scratches are visible under the bright field conditions of a microscope, but they can still be seen under phase contrast lighting.

The quality of polishing significantly affects the sample’s microstructure and has increasingly garnered the attention of experts.

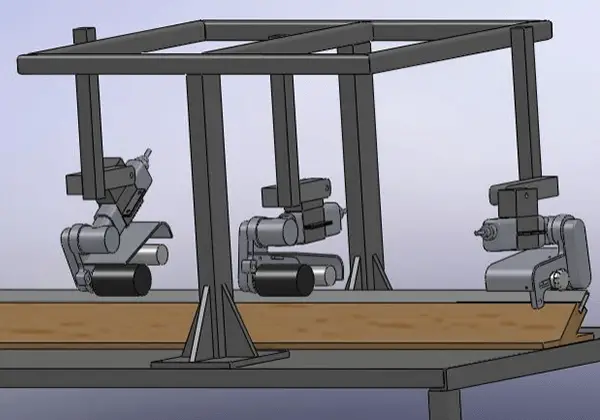

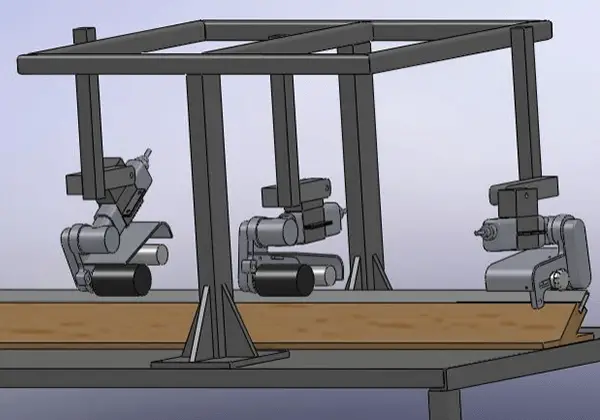

In recent years, considerable research has been conducted domestically and internationally on the performance of polishing machines, resulting in numerous new models and generations of polishing equipment, transitioning from manual operation to various semi-automatic and fully automatic polishers.

Here, we introduce the performance and features of several commonly used mechanical polishers.

These machines are specifically designed to process the surfaces of steel, aluminum, copper, and other metal products and tubes. Dozens of original factory accessories cater to different requirements, effortlessly creating a variety of finishes such as snowflakes, brushed patterns, waves, matte surfaces, and mirrors.

They can swiftly repair deep scratches and minor scrapes, as well as quickly grind and polish welds, watermarks, oxidized films, stains, and paint. They are suitable for deburring, rounding corners, and decorative metal processing.

During operation, they do not create shadows, transition zones, or uneven decorative surfaces, making them crucial equipment in the metal product production line.

Polishing machines are applicable in the following industries: