How can you accurately bend a sheet metal part without trial and error? The Y-factor holds the key. This article explains the Y-factor, a crucial constant used to calculate the unfolded length of bent sheet metal parts. Understanding this factor can improve precision in your metalworking projects, ensuring consistent results. Dive into the details of how the Y-factor is determined, its numerical range, and its practical applications. Unlock this knowledge to enhance your fabrication accuracy and efficiency.

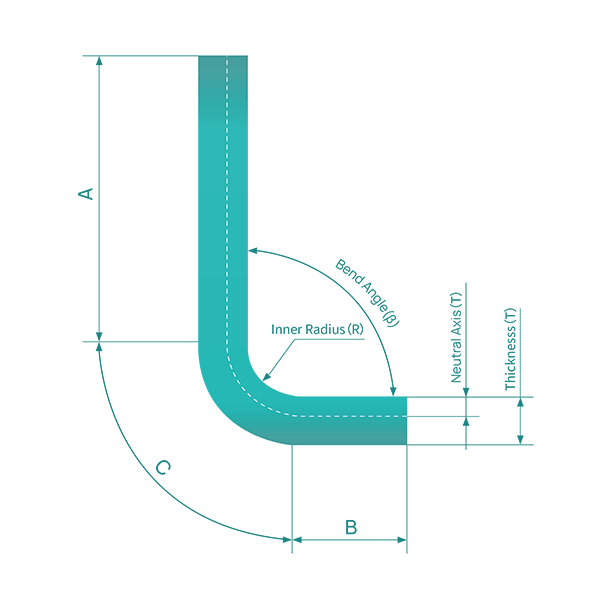

The Y-factor is a critical constant used in sheet metal fabrication to calculate the unfolded length of a part when it undergoes bending at a specific radius and angle. This factor is essential for accurate flat pattern development and bend allowance calculations in sheet metal design and manufacturing.

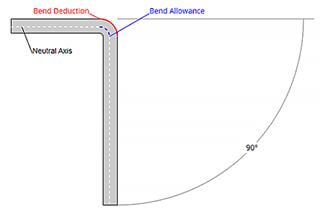

The Y-factor is determined by the location of the neutral axis (or neutral bending line) relative to the material thickness. This position varies depending on the material properties, particularly its ductility and work-hardening characteristics. For instance, more ductile materials tend to have a neutral axis closer to the inside of the bend, resulting in a lower Y-factor.

Numerically, the Y-factor ranges from 0 to 1, with values typically falling between 0.3 and 0.5 for most common sheet metal materials. A lower Y-factor generally indicates a softer, more ductile material, while a higher value suggests a harder, less ductile material. It’s important to note that the Y-factor is not negative; rather, smaller positive values correspond to softer materials.

The Y-factor is intimately related to the K-factor, another important constant in sheet metal bending. The relationship between these factors is expressed as:

Y-factor = K-factor × (π/2)

Where π is approximately 3.14159. This relationship allows for easy conversion between the two factors, which are sometimes used interchangeably in different design and manufacturing environments.

In practice, the default Y-factor of 0.50 is often used as a starting point for many materials. However, for precise calculations, especially in critical applications or when working with non-standard materials, it’s crucial to determine the exact Y-factor through material testing or empirical methods.

Understanding and correctly applying the Y-factor is vital for achieving accurate bend calculations, minimizing material waste, and ensuring the proper fit and function of sheet metal components in assembly.

Further reading:

Below are answers to some frequently asked questions:

The Y-factor in sheet metal bending is a critical concept used to refine the calculations involving the K-factor by accounting for the material’s elasticity. It is derived from the K-factor and is crucial for making precise bend predictions. The Y-factor is calculated using the formula:

[ Y \text{-factor} = \frac{K \text{-factor} \times \pi}{2} ]

This formula adjusts the K-factor, which represents the ratio between the neutral axis and the material’s thickness, to include the material’s elastic properties. This adjustment allows for more accurate predictions of how the material will stretch or compress during the bending process, which is essential in industries that require exact tolerances, such as aerospace, automotive, and electronics manufacturing.

The Y-factor plays a significant role in calculating the bend allowance, ensuring that the final dimensions of the bent part closely match the design specifications. By considering the material’s elasticity, the Y-factor helps achieve high-quality results in sheet metal fabrication, making it a more accurate predictor than the K-factor alone. The default value of the Y-factor is often set at 0.5 but can be adjusted based on the specific material properties and project requirements.

The Y-factor and K-factor in sheet metal bending are closely related but serve distinct purposes and are calculated differently. The K-factor is a dimensionless constant that represents the ratio of the distance from the neutral axis to the inner surface of the bend, relative to the material’s total thickness. It is crucial for calculating bend allowances and deductions, indicating how the material will behave during bending. The neutral axis is the line within the material where no stretching or compressing occurs. The K-factor typically ranges between 0.3 and 0.5, depending on the material type, bend radius, and forming method. It is calculated by dividing the distance from the neutral axis to the inner bend radius by the material’s total thickness.

On the other hand, the Y-factor is a refinement of the K-factor, taking into account the material’s elastic properties to provide more precise bend calculations. It is calculated by multiplying the K-factor by π (pi) and then dividing the result by 2, expressed as ( Y =K x T / 2 ). The Y-factor is particularly useful in high-precision applications, such as complex or high-tolerance sheet metal parts, where accurate predictions of material deformation are critical.

The key differences between the two are:

In summary, the Y-factor builds upon the K-factor by incorporating additional mathematical adjustments to provide more accurate and precise bend calculations, particularly important in high-tolerance sheet metal fabrication.

The Y-factor is important in sheet metal fabrication because it provides a higher level of accuracy and precision in the bending process. By accounting for the material’s elasticity, the Y-factor enables more precise predictions of how the material will behave under bending stresses. This is crucial for industries that require high precision, such as aerospace, automotive, and electronics manufacturing.

The Y-factor refines the K-factor, which is a simple ratio of the neutral axis to the material’s thickness, by incorporating the material’s elastic properties. This consideration ensures that the final dimensions of the bent part are accurate, helping engineers achieve better control over the stretching or compressing of the material during bending. Accurate calculation of the Y-factor leads to precise bend allowances and deductions, which are essential for achieving the desired specifications in various types of bends.

Moreover, the Y-factor helps reduce errors and waste by ensuring that the length of material required and the position of the bend are precise. This is particularly important in custom and high-tolerance parts where standard values may not be sufficient. In summary, the Y-factor is vital for enhancing the accuracy of bend calculations, reducing material waste, and achieving precise results in sheet metal fabrication.

To calculate the Y-factor in sheet metal bending, you need to understand its relationship with the K-factor, which represents the neutral axis’s position during bending. The Y-factor refines the K-factor by accounting for the material’s elastic properties.

First, determine the K-factor, which is the ratio of the distance from the neutral axis to the inner bend radius over the material thickness. The formula for the K-factor is:

where (δ) is the distance from the neutral axis to the inner bend radius, and (T) is the material thickness.

Next, use the K-factor to calculate the Y-factor with the following formula:

For example, if the K-factor is 0.318, the Y-factor would be:

Alternatively, if you have the Y-factor and need to find the K-factor, you can use the formula:

The Y-factor is crucial in bend allowance calculations to ensure precise bend dimensions by accounting for material elasticity. The bend allowance formula incorporating the Y-factor is:

where (L) is the unfolded length, (R) is the inner radius, (Y) is the Y-factor, (T) is the material thickness, and (\Theta) is the bending angle in degrees.

By using the Y-factor alongside the K-factor, engineers can predict metal sheet behavior under bending stresses more accurately, ensuring the final dimensions meet specifications.

The Y-factor is most commonly used in industries where precise sheet metal bending is essential for achieving high accuracy and meeting stringent specifications. These industries include aerospace, automotive, electronics, and general manufacturing.

In the aerospace industry, the Y-factor is critical for ensuring the safety and performance of aircraft and spacecraft components by achieving precise tolerances in bend calculations. The automotive industry relies on the Y-factor for manufacturing body panels, chassis parts, and other structural elements with the required precision. In electronics, the Y-factor is essential for creating enclosures, casings, and other components that demand tight tolerances and complex geometries. Lastly, in general manufacturing, the Y-factor helps improve the accuracy of sheet metal bending for machinery, appliances, and other products where sheet metal parts are integral to the design.

Overall, the Y-factor is a vital tool for engineers in these industries to predict and control the deformation of metal sheets during the bending process, ensuring the final product meets design specifications.