What if the choice between zinc and aluminum could revolutionize your manufacturing process? In the world of die casting, understanding the strengths and weaknesses of each material is crucial. This article breaks down the differences, costs, and applications of zinc and aluminum die casting, giving you the insights needed to make informed decisions. Discover how these metals can impact your product’s durability, precision, and overall performance. Dive in to learn which material best suits your needs and why it matters.

Die casting is the process of injecting molten metal into a mold and forming the desired shape under pressure. Zinc die casting and aluminum die casting are two common types of die casting.

Zinc die casting refers to the process of injecting molten zinc material into a mold and forming a product under pressure, while aluminum die casting refers to injecting molten aluminum material into a mold and forming a product under pressure.

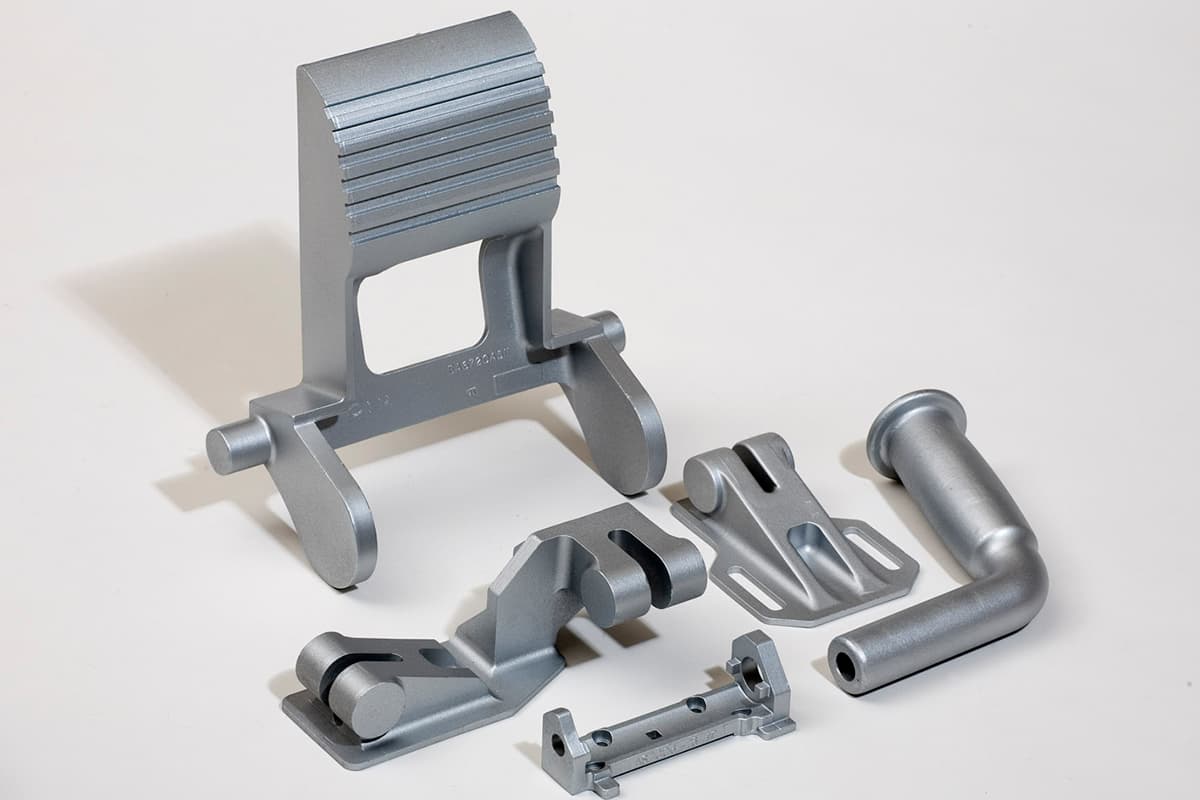

In industrial and civilian applications, die-cast products of zinc and aluminum are used extensively, such as in automobile parts, building accessories, furniture fittings, etc.

Next, let’s delve into the differences and application scenarios of zinc die casting and aluminum die casting.

Zinc alloys and aluminum alloys are comparably priced, and if the structure and casting process allow, it’s more cost-effective to use aluminum alloys.

Given that the specific gravity of zinc alloys is about 2.5 times that of aluminum alloys, and the price is similar, the material cost of zinc alloys is two to three times that of aluminum alloys.

Many companies are looking to replace zinc alloys with aluminum alloys to save costs, but this isn’t always possible because zinc alloys have much better strength, hardness, and moldability.

If your product requires high-quality surface polishing and electroplating, you’ll have no choice but to use zinc alloys.

Achieving high surface quality with aluminum alloys is challenging due to their inferior casting performance, which often results in many surface pores and poor quality after electroplating.

The performance of zinc alloy die casting is superior, with many advantages.

Zinc alloys have a low melting point, a narrow solidification temperature range, are easy to fill and shape, and have a smaller tendency to produce shrinkage holes.

They can cast complex, thin-walled precision parts, with smooth surfaces and high dimensional accuracy.

The lower casting temperature extends the mold’s lifespan, prevents sticking, and doesn’t corrode the mold.

Additionally, zinc alloys have higher room-temperature mechanical properties, particularly in compression and wear resistance.

Zinc alloy die castings can accept various surface treatments, such as electroplating, spraying, and painting.

The most severe drawback of zinc alloys is aging, which leads to volume expansion, strength reduction, and over time, can result in die castings becoming deformed or even fracturing. This is the main reason why the use of zinc alloys is limited.

Aluminum alloys significantly outperform zinc alloys in terms of properties, boasting excellent die casting performance, electrical conductivity, and thermal conductivity, and decent machinability.

However, they have some notable disadvantages. Alloys in the aluminum-silicon series are prone to sticking and have a corrosive effect on metal crucibles. They also shrink significantly, which can cause shrinkage holes.

Because they affect molds differently, the prices of molds used for zinc alloy and aluminum alloy die casting also vary.

Zinc alloy die casting is less prone to sticking and doesn’t corrode molds, so the molds used for this process tend to be cheaper.

On the other hand, molds for aluminum alloy die casting are usually more expensive due to sticking and corrosiveness towards metal crucibles.

The process flow of zinc die casting mainly includes mold design, alloy melting and casting, injection, molding, cleaning, and spraying. The specific process is as follows:

Mold Design: A suitable mold is designed according to the required shape and size.

Alloy Melting and Casting: The required casting alloy is added to the melting furnace, and after melting, it is poured into the injection machine.

Injection: The molten alloy is injected into the mold and enough pressure is applied to fill the entire mold.

Molding: After the alloy cools down, the finished product is removed from the mold.

Cleaning: The cooled product is cleaned to remove the substance leftover from the mold.

Spraying: If necessary, a protective layer or color treatment is sprayed onto the surface of the product.

The advantages of zinc die casting are that it can manufacture products with precise dimensions and shapes, smooth surfaces, high density, high strength, and good corrosion resistance. Therefore, zinc die casting is widely used in a variety of application scenarios, such as automobile parts, furniture fittings, mechanical components, apparel accessories, etc.

The process of aluminum die casting is similar to that of zinc die casting, which mainly includes mold design, melting of casting alloys, injection, molding, cleaning, and spraying. The specific process is as follows:

Mold Design: Design a suitable mold according to the required shape and size.

Melting of Casting Alloys: Add the required casting alloys to the furnace. After melting, pour them into the injection machine.

Injection: Inject the melted alloy into the mold and apply enough pressure to fill the entire mold.

Molding: After the alloy cools down, remove the product from the mold.

Cleaning: Clean the cooled product to remove the residual substance from the mold.

Spraying: Spray a protective layer or color treatment on the product surface as needed.

The advantages of aluminum die casting are fast shaping, good heat transfer performance, light weight, and high surface quality. It can produce complex and varied shapes. Aluminum die casting is mainly used in the fields of automobile parts, aviation parts, electronic equipment parts, communication parts, etc.

Through the above analysis, we can conclude that the process flow of zinc die casting and aluminum die casting is similar, but their application scenarios are slightly different.

Zinc die casting is characterized by high density, high strength, good corrosion resistance, and is mainly used for automobile parts, furniture accessories, mechanical components, clothing accessories, etc.

Aluminum die casting has the advantages of fast shaping, good heat transfer performance, light weight, and high surface quality, and is suitable for automobile parts, aviation parts, electronic equipment parts, communication parts, etc.