Have you ever struggled to accurately calculate the weight of zinc for your projects? This article introduces an online zinc weight calculator that simplifies this task using zinc’s standard density of 7.135g/cm³. Learn how to adjust for different densities and use the tool efficiently. Expect clear instructions and tips to ensure precise weight calculations for your zinc materials.

Accurately calculating the weight of zinc is essential in industries such as manufacturing, construction, and engineering. Whether designing components, estimating costs, or ensuring structural integrity, understanding zinc weight is crucial for effective planning and execution.

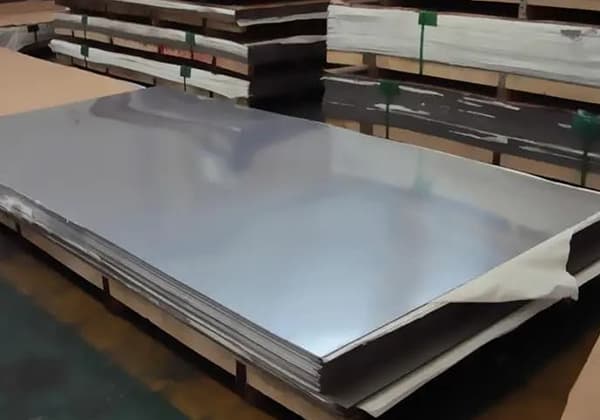

Imagine a scenario where a construction company needs to install a zinc roof. Knowing the precise weight of the zinc sheets is vital for determining the load-bearing capacity of the building’s framework. An incorrect calculation could lead to structural failures, increased costs, or even safety hazards. This example underscores the importance of accurate zinc weight calculation.

Accurate zinc weight calculations are critical for several reasons:

Several factors influence the calculation of zinc weight:

This zinc weight calculator utilizes a standard zinc density of 7.135 g/cm³. However, recognizing the variability in zinc alloy compositions and manufacturing processes, we’ve incorporated flexibility into our tool. If your specific zinc material deviates from this standard density, you can easily customize the calculation by entering your material’s precise density in the designated input field.

For your convenience, we’ve included a comprehensive metal density reference table. This table provides density values for various metals and alloys, enabling accurate calculations for a wide range of materials commonly used in industrial applications.

To expand your material weight estimation capabilities beyond zinc, we recommend exploring our versatile metal weight calculator. This advanced tool accommodates a broad spectrum of metals and alloys, offering precise weight calculations based on dimensions and specific material properties.

By integrating precise density values and flexible input options, this calculator serves as a valuable tool for engineers, manufacturers, and material scientists engaged in zinc-based product design, fabrication cost estimation, and quality control processes.

Knowing the weight of zinc materials is essential in various industries such as construction, manufacturing, and engineering. Accurate weight calculation helps in designing structures, estimating costs, and ensuring safety standards. This chapter provides detailed formulas for calculating the weight of zinc in different shapes, including flat sheets, round bars, and hollow tubes.

To calculate the weight of a zinc flat sheet, use the following formula:

Where:

Example Calculation:

Next, we will explore the weight calculation for round bars, which is another common shape of zinc material.

For calculating the weight of a zinc round bar, use this formula:

Where:

Example Calculation:

Next, we will look at the weight calculation for hollow tubes.

To calculate the weight of a zinc hollow tube, use the following formula:

Where:

Example Calculation:

Understanding and applying these formulas allows for precise weight calculations, which are crucial for various applications in engineering, manufacturing, and construction.

Density is a fundamental property of materials that indicates how much mass is contained within a specific volume. For zinc, understanding its density is crucial for accurate weight calculations, which are essential in various industries such as construction, manufacturing, and engineering. Accurate knowledge of zinc’s density ensures precise calculations, structural integrity, and cost-effectiveness in projects.

To measure the density of zinc, follow these steps:

Understanding the common units of zinc density is essential for converting measurements and performing accurate calculations. Zinc density is typically expressed in the following units:

This unit is commonly used in scientific contexts. The density of zinc is approximately 7.14 g/cm³ at room temperature (20°C).

In certain industries, especially in the United States, density might be expressed in pounds per gallon. For zinc, the density is approximately 59.6 lbs/gal.

For precision in smaller components, density can be expressed in pounds per cubic inch. Zinc has a density of about 0.2576 lbs/in³.

In metric measurements, particularly in construction and engineering, density is often given in kilograms per cubic meter. The density of zinc in these terms is approximately 7140 kg/m³.

Several factors can influence the density of zinc:

Understanding zinc density is critical for several practical applications:

Zinc density also has environmental and economic implications:

By grasping the concept of zinc density and its common units, you can perform precise weight calculations for various zinc applications, ensuring the success and safety of your projects.

Accurate zinc weight calculations are crucial in various practical applications across multiple industries. Understanding the weight of zinc materials ensures proper design, cost estimation, structural integrity, and efficient use of resources. Here are some key areas where zinc weight calculations play a vital role:

In engineering and manufacturing, precise weight calculations are essential for designing components that meet specific performance and safety standards. For instance, in the automotive industry, zinc alloys such as Zamak 3 and Zamak 5 are used to produce lightweight yet durable parts. Knowing the exact weight of these components helps engineers optimize designs for fuel efficiency and structural strength. For example, reducing the weight of a car by just 10% can improve fuel economy by 6-8%, highlighting the importance of accurate weight calculations.

Accurate weight calculations help manufacturers estimate costs and plan budgets. For example, a company producing zinc die-cast parts must calculate the weight of zinc needed for each batch to forecast expenses accurately. Inaccurate calculations can lead to financial losses or project delays. For instance, overestimating the weight could result in excess material costs, while underestimating it might cause production halts due to material shortages. In 2022, a manufacturing firm reported a 15% cost saving by improving the accuracy of their zinc weight calculations.

Accurate weight calculations are critical for quality control and regulatory compliance. In sectors like aerospace, where precision is paramount, the weight of zinc components must adhere to strict specifications to ensure safety and performance. Calculations help verify that parts meet industry standards and avoid costly recalls or failures. For example, zinc components used in aircraft must meet stringent weight specifications to ensure they do not compromise flight safety.

In construction, understanding the weight of zinc materials is vital for load-bearing calculations. Zinc is often used in roofing and cladding due to its corrosion resistance and durability. Calculating the weight of zinc sheets ensures that the building’s framework can support the load, preventing structural failures. For example, a standard zinc sheet weighs about 7.2 kg per square meter, and knowing this helps in designing appropriate support structures.

Zinc is also used in structural elements such as beams and supports. Accurate weight calculations help civil engineers design structures that can withstand various loads and stresses. For instance, in bridge construction, knowing the weight of zinc-coated steel beams is essential for ensuring the bridge’s stability and longevity. A well-known example is the use of zinc-coated steel in the Brooklyn Bridge, which has helped it withstand the elements for over a century.

During renovation or retrofitting projects, precise weight calculations are necessary to ensure that additional zinc materials do not compromise the existing structure. For example, adding zinc cladding to an old building requires careful assessment of the weight to avoid overloading the original framework. Accurate calculations help in making informed decisions about material selection and structural reinforcement.

For DIY enthusiasts and home improvement projects, zinc weight calculations are essential for planning and executing tasks efficiently. Whether building a garden shed, crafting custom furniture, or installing zinc countertops, knowing the weight of zinc materials helps ensure proper handling and installation. For example, a zinc countertop typically weighs around 20-25 pounds per square foot, which is crucial information for ensuring that the underlying cabinets can support the weight.

Artists and crafters often use zinc sheets and rods for various projects, such as sculptures and decorative pieces. Accurate weight calculations enable them to estimate the amount of material needed, manage costs, and ensure the final product’s stability and durability. For instance, a sculptor working with zinc must know the weight to ensure that the base can support the entire structure safely.

Hobbyist metalworkers frequently use zinc in their projects due to its malleability and corrosion resistance. Calculating the weight of zinc pieces helps them select appropriate materials and tools, ensuring safe and successful fabrication. For example, when casting zinc parts, knowing the weight helps in determining the amount of molten metal required, preventing wastage and ensuring project success.

Below are answers to some frequently asked questions:

The density of zinc is approximately 7,130 kg/m³. This value is widely accepted and consistently reported in various reliable sources.

To calculate the weight of a zinc sheet, you need to use a formula that incorporates the dimensions of the sheet and the density of zinc. The formula is:

Here are the steps to follow:

For example, if you have a zinc sheet with dimensions:

Using the density of zinc as 7,100 kg/m³:

This calculation provides the weight of the zinc sheet in kilograms. If you are working with different units, ensure to convert them accordingly to maintain consistency in the calculation.

The accuracy of online zinc weight calculators can be quite reliable, but it largely depends on several factors. These calculators work by taking input data such as the dimensions of the zinc piece and applying formulas that incorporate the known density of zinc, which is approximately 7.14 g/cm³. For simple shapes like bars, the volume is calculated using the dimensions provided, and this volume is then multiplied by the density to determine the weight.

However, the precision of the calculation is heavily influenced by the accuracy of the input data. Any small errors in the dimensions entered can lead to significant discrepancies in the calculated weight. Therefore, it is crucial to ensure that measurements are accurate and that any necessary unit conversions are correctly applied.

For more complex applications, such as determining the weight of a zinc coating on a surface, additional factors like the thickness of the coating and the area covered need to be considered. In these cases, the calculation involves more variables, and the results can be less precise if not all factors are accurately accounted for.

While most online zinc weight calculators are designed to provide fairly reliable estimates, they should primarily be used for estimation purposes. It is advisable to verify the results with additional checks if high precision is required. In summary, online zinc weight calculators can be accurate if they use correct formulas, accurate densities, and precise input data, but they are best used for generating approximate weights rather than exact measurements.

Yes, you can use the same formula for different shapes of zinc oxide (ZnO). The chemical formula ZnO remains consistent regardless of the particle shape or morphology because the chemical composition and bonding between zinc and oxygen atoms do not change.

Zinc oxide can crystallize in two main forms: hexagonal wurtzite and cubic zincblende, with the wurtzite form being the most stable and commonly found. This crystalline structure is determined by the synthesis conditions and not by the particle shape.

Physical properties such as molecular weight, density, and melting/boiling points remain the same across different shapes of ZnO particles, as these properties are intrinsic to the ZnO compound itself.

ZnO particles can be synthesized in various shapes like spheres and rods, and in different size ranges from nano to micro scale. While the shape and size can influence the particle’s behavior in specific applications, the fundamental chemical and structural formula remains unchanged.

Knowing the weight of zinc materials is important for several key reasons that impact the quality, performance, and cost-effectiveness of galvanized steel products. Firstly, the weight of the zinc coating is directly related to the corrosion protection and durability of the steel. Thicker zinc coatings provide better protection against rust and corrosion by forming a barrier that shields the steel from environmental factors like moisture and oxygen, thus extending the steel’s lifespan.

Additionally, accurate measurement of zinc coating weight is crucial for quality control and compliance with industry standards, such as those set by ASTM. Ensuring that the coating weight meets these standards during production helps manufacturers avoid costly rework or scrapping of non-compliant material.

From a production standpoint, measuring the zinc coating weight in real-time using technologies like X-ray fluorescence (XRF) allows for immediate adjustments, optimizing production efficiency and reducing costs. This prevents excessive zinc use and minimizes the risk of producing substandard products.

Uniformity and consistency in coating weight are also essential for the overall quality of galvanized steel. Variations can lead to inconsistent performance and appearance, which is why automatic coating weight control systems are important for maintaining uniform application.

Finally, the weight and uniformity of the zinc coating are critical for the environmental and structural integrity of the steel, especially in demanding applications such as construction and automotive manufacturing. Consistent and adequate coating weight ensures that the steel remains protected and structurally sound over time.

In summary, knowing the weight of zinc materials is vital for ensuring the quality, durability, compliance, production efficiency, and structural integrity of galvanized steel products.