1. What Is Bend Allowance?

The bend allowance is statistical data that has been accumulated by experienced mold designers over the years.

Subsequently, mold designers can use this data in the calculation formula to determine the unfold size of various sheet metals.

Hence, the bend allowance is a tool for mold designers to calculate the unfold dimensions of press bent parts.

The functions of bend allowance:

Punch mold designers know that the first step in the design process is to reverse the bend structure into a flat structure, step by step, once they have received the product drawings from the customer.

They then proceed to punch the flat structure and design the bending mold to meet the customer’s requirements.

The mold structure design must not only meet the customer’s drawing requirements, but also the drawing dimension tolerance requirements for precision.

The biggest challenge lies in ensuring the accuracy of the relevant unfold dimensions of stamping and bending.

2. How to Calculate Bend Allowance?

After learning about bend allowance, the next step is to calculate it.

You can directly use our bend allowance calculator to calculate the bending allowance.

Besides, the fabrication calculator can also help you calculate K-factor, Y-factor, bend allowance, bend deduction, etc.

In one of our blog post we make a very detailed analysis on this, so go ahead and check out the method to calculate the bend allowance.

3. Bend Allowance Chart

(1) Bend allowance chart for 88° & 90° bending

| Material | Thickness | Deduction | Inside R | Angle | Die | Punch | ||

|---|---|---|---|---|---|---|---|---|

| R | V Width | R | Angle | |||||

| Steel Plate | 0.8 | 1.5 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° |

| 0.9 | 1.7 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° | |

| 1 | 1.8 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 1.91 | 1 | 90° | 0.4 | 6 | 0.2 | 88° | |

| 1.2 | 2.1 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.5 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| Cold Rolled Plate | 1.6 | 2.65 | 1.3 | 90° | 0.5 | 8 | 0.6 | 88° |

| 1.8 | 3.4 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2 | 3.5 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.3 | 3.75 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3 | 5.05 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 4 | 6.9 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| Hot Rolled Plate | 2.3 | 3.77 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° |

| 3.2 | 5.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 4.2 | 7.4 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| 4.8 | 8.1 | 4 | 90° | 0.8 | 25 | 0.6 | 88° | |

| Aluminum Plate | 0.8 | 1.5 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° |

| 1 | 1.6 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 2.1 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.45 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.6 | 2.7 | 1.3 | 90° | 0.5 | 8 | 0.6 | 88° | |

| 1.6 | 2.4 | 1.3 | 90° | 0.6 | 10 | 0.6 | 88° | |

| 2 | 3.25 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.3 | 3.6 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.5 | 16 | 0.6 | 88° | |

| 3 | 4.7 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.2 | 5 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.5 | 5.9 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 4 | 6.8 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 5 | 8.1 | 4 | 90° | 0.8 | 25 | 3.2 | 88° | |

| Copper Plate | 0.8 | 1.6 | 1.3 | 90° | 0.5 | 6 | 0.2 | 88° |

| 1 | 1.9 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.2 | 2.15 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 1.5 | 2.55 | 1.3 | 90° | 0.5 | 8 | 0.2 | 88° | |

| 2 | 3.5 | 2 | 90° | 0.8 | 12 | 0.6 | 88° | |

| 2.5 | 4.2 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3 | 5 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.2 | 5.1 | 2.6 | 90° | 0.8 | 16 | 0.6 | 88° | |

| 3.5 | 6 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

| 4 | 7 | 4 | 90° | 0.8 | 25 | 1.5 | 88° | |

(2) Sheet metal bending allowance table (iron, aluminum, copper)

| T | Cold-rolled steel sheet SPCC (electro-galvanized sheet SECC) | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| V4 | 90 | 0.9 | 1.4 | 2.8 | |||||||||||

| 120 | 0.7 | ||||||||||||||

| 150 | 0.2 | ||||||||||||||

| V6 | 90 | 1.5 | 1.7 | 2.15 | 4.5 | ||||||||||

| 120 | 0.7 | 0.86 | 1 | ||||||||||||

| 150 | 0.2 | 0.3 | 0.4 | ||||||||||||

| V7 | 90 | 1.6 | 1.8 | 2.1 | 2.4 | 5 | |||||||||

| 120 | 0.8 | 0.9 | 1 | ||||||||||||

| 150 | 0.3 | 0.3 | 0.3 | ||||||||||||

| V8 | 90 | 1.6 | 1.9 | 2.2 | 2.5 | 5.5 | |||||||||

| 30 | 0.3 | 0.34 | 0.4 | 0.5 | |||||||||||

| 45 | 0.6 | 0.7 | 0.8 | 1 | |||||||||||

| 60 | 1 | 1.1 | 1.3 | 1.5 | |||||||||||

| 120 | 0.8 | 0.9 | 1.1 | 1.3 | |||||||||||

| 150 | 0.3 | 0.3 | 0.2 | 0.5 | |||||||||||

| V10 | 90 | 2.7 | 3.2 | 7 | |||||||||||

| 120 | 1.3 | 1.6 | |||||||||||||

| 150 | 0.5 | 0.5 | |||||||||||||

| V12 | 90 | 2.8 | 3.65 | 4.5 | 8.5 | ||||||||||

| 30 | 0.5 | 0.6 | 0.7 | ||||||||||||

| 45 | 1,0 | 1.3 | 1.5 | ||||||||||||

| 60 | 1.7 | 2 | 2.4 | ||||||||||||

| 120 | 1.4 | 1.7 | 2 | ||||||||||||

| 150 | 0.5 | 0.6 | 0.7 | ||||||||||||

| V14 | 90 | 4.3 | 10 | ||||||||||||

| 120 | 2.1 | ||||||||||||||

| 150 | 0.7 | ||||||||||||||

| V16 | 90 | 4.5 | 5 | 11 | |||||||||||

| 120 | 2.2 | ||||||||||||||

| 150 | 0.8 | ||||||||||||||

| V18 | 90 | 4.6 | 13 | ||||||||||||

| 120 | 2.3 | ||||||||||||||

| 150 | 0.8 | ||||||||||||||

| V20 | 90 | 4.8 | 5.1 | 6.6 | 14 | ||||||||||

| 120 | 2.3 | 3.3 | |||||||||||||

| 150 | 0.8 | 1.1 | |||||||||||||

| V25 | 90 | 5.7 | 6.4 | 7 | 17.5 | ||||||||||

| 120 | 2.8 | 3.1 | 3.4 | ||||||||||||

| 150 | 1 | 1 | 1.2 | ||||||||||||

| V32 | 90 | 7.5 | 8.2 | 22 | |||||||||||

| 120 | 4 | ||||||||||||||

| 150 | 1.4 | ||||||||||||||

| V40 | 90 | 8.7 | 9.4 | 28 | |||||||||||

| 120 | 4.3 | 4.6 | |||||||||||||

| 150 | 1.5 | 1.6 | |||||||||||||

| T | Aluminum sheet L2Y2 material | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| V4 | 1.4 | 2.8 | |||||||||||||

| V6 | 1.6 | 4.5 | |||||||||||||

| V7 | 1.6 | 1.8 | 5 | ||||||||||||

| V8 | 1.8 | 2.4 | 3.1 | 5.5 | |||||||||||

| V10 | 2.4 | 3.2 | 7 | ||||||||||||

| V12 | 2.4 | 3.2 | 8.5 | ||||||||||||

| V14 | 3.2 | 10 | |||||||||||||

| V16 | 3.2 | 4 | 4.8 | 11 | |||||||||||

| V18 | 4.8 | 13 | |||||||||||||

| V20 | 4.8 | 14 | |||||||||||||

| V25 | 4.8 | 5.4 | 6 | 17.5 | |||||||||||

| V32 | 6.3 | 6.9 | 22 | ||||||||||||

| T | Copper sheet | ||||||||||||||

| V | Angle | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 4.5 | 5 | Min dimension | Note |

| 90 | 3.6 | 5.2 | 6.8 | 8.4 | 28 | ||||||||||

| 120 | |||||||||||||||

| 150 | |||||||||||||||

Note: (For C-shaped profiles with a thickness of 2.0, the V12 coefficient is 3.65, while other 2.0 sheet materials have a coefficient of 3.5.) The bending allowance coefficient for 2.0 sheet with hemming is 1.4.

- 6.0mm copper sheet bending allowance: 10.3

- 8.0mm copper sheet bending allowance: 12.5

- 10.0mm copper sheet bending allowance: 15

- 12.0mm copper sheet bending allowance: 17

- 3.0mm stainless steel with V25 allowance: 6

- 3.0mm stainless steel with V20 allowance: 5.5

- For copper plates thicker than 6.0, the allowance for the lower die is V40

(3) Amada bend allowance chart

| MATERLAL | SPCC | SUS | LY12 | SECC | ||||

| T | ΔT | ΔK | ΔT | ΔK | ΔT | ΔK | ΔT | ΔK |

| T=0.6 | 1.25 | 1.26 | ||||||

| T=0.8 | 0.18 | 1.42 | 0.15 | 1.45 | 0.09 | 1.51 | ||

| T=1.0 | 0.25 | 1.75 | 0.2 | 1.8 | 0.3 | 1.7 | 0.38 | 1.62 |

| T=1.2 | 0.45 | 1.95 | 0.25 | 2.15 | 0.5 | 1.9 | 0.43 | 1.97 |

| T=1.4 | 0.64 | 2.16 | ||||||

| T=1.5 | 0.64 | 2.36 | 0.5 | 2.5 | 0.7 | 2.3 | ||

| T=1.6 | 0.69 | 2.51 | ||||||

| T=1.8 | 0.65 | 3 | ||||||

| T=1.9 | 0.6 | 3.2 | ||||||

| T=2.0 | 0.65 | 3.35 | 0.5 | 3.5 | 0.97 | 3.03 | 0.81 | 3.19 |

| T=2.5 | 0.8 | 4.2 | 0.85 | 4.15 | 1.38 | 3.62 | ||

| T=3.0 | 1 | 5 | 5.2 | 1.4 | 4.6 | |||

| T=3.2 | 1.29 | 5.11 | ||||||

| T=4.0 | 1.2 | 6.8 | 1 | 7 | ||||

| T=5.0 | 2.2 | 7.8 | 2.2 | 7.8 | ||||

| T=6.0 | 2.2 | 9.8 | ||||||

(4) Aluminum sheet bending allowance table

| Aluminum sheet thickness | Bending angle | Bend allowance |

| AL-0.8 | 90 | 1.5 |

| AL-1.0 | 90 | 1.5 |

| 45, 135 | 0.5 | |

| AL-1.2 | 90 | 2.0 |

| 45, 135 | 0.5 | |

| AL-1.5 | 90 | 2.5 |

| 45, 135 | 0.5 | |

| 60, 120 | 1.5 | |

| AL-2.0 | 90 | 3.0 |

| 45, 135 | 1.0 | |

| 60, 120 | 2.5 | |

| 90-degree groove | 1.5 | |

| AL-2.5 | 90 | 4.0 |

| 45, 135 | 1.5 | |

| 60, 120 | 3.0 | |

| 90-degree groove | 2.0 | |

| AL-3.0 | 90 | 5.0 |

| 45, 135 | 3.0 | |

| 60, 120 | 4.5 | |

| 90-degree groove | 2.5 |

(5) 0°-180° sheet metal bending allowance table

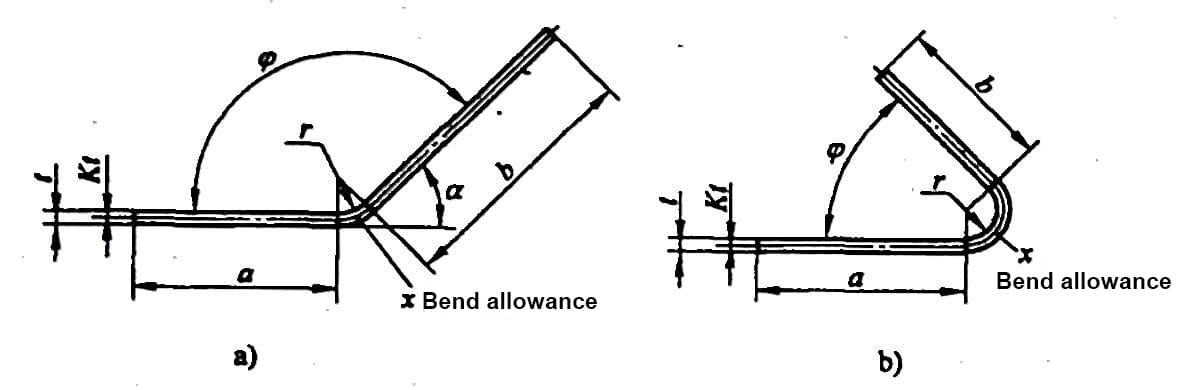

a) φ>90° b)≤90°

1) The bending allowance table is applicable for sheet metal bending processes where no pressure plate is used, and the width of the plate is greater than three times the thickness.

2) When bending on a press brake machine, calculations can be made according to this table.

3) As per the dimensions marked in the diagram, the calculation formula for the unfolded dimensions of the bent workpiece is as follows:

L = a + b + x

In this equation,

- L – the unfolded dimensions of the bent workpiece;

- a and b – the lengths of the straight sides of the bent workpiece as marked in the diagram;

- x – the bending coefficient of the bent workpiece.

4) Due to the numerous factors affecting sheet metal bending, this bending allowance table for sheet metal bending should be used as a reference only.

- Bend allowance values for bending angle φ=20°

- Bend allowance values for bending angle φ=25°

- Bend allowance values for bending angle φ=30°

- Bend allowance values for bending angle φ=35°

- Bend allowance values for bending angle φ=40°

- Bend allowance values for bending angle φ=45°

- Bend allowance values for bending angle φ=50°

- Bend allowance values for bending angle φ=55°

- Bend allowance values for bending angle φ=60°

- Bend allowance values for bending angle φ=65°

- Bend allowance values for bending angle φ=70°

- Bend allowance values for bending angle φ=75°

- Bend allowance values for bending angle φ=80°

- Bend allowance values for bending angle φ=85°

- Bend allowance values for bending angle φ=90°

- Bend allowance values for bending angle φ=95°

- Bend allowance values for bending angle φ=100°

- Bend allowance values for bending angle φ=105°

- Bend allowance values for bending angle φ=110°

- Bend allowance values for bending angle φ=115°

- Bend allowance values for bending angle φ=120°

- Bend allowance values for bending angle φ=125°

- Bend allowance values for bending angle φ=130°

- Bend allowance values for bending angle φ=135°

- Bend allowance values for bending angle φ=140°

- Bend allowance values for bending angle φ=145°

- Bend allowance values for bending angle φ=150°

- Bend allowance values for bending angle φ=155°

- Bend allowance values for bending angle φ=160°

- Bend allowance values for bending angle φ=165°

- Bend allowance values for bending angle φ=170°

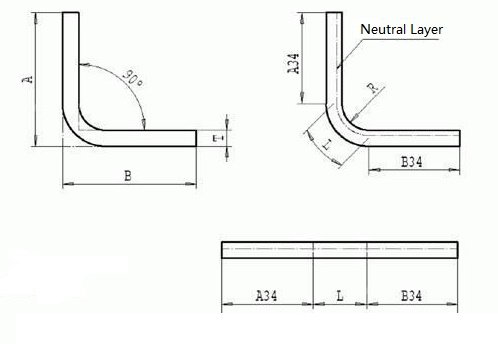

4. Calculate Unfold Size With Bend Allowance Chart

Bend forming 0°L=A+B-0.43T, T=Thickness, Deduction=0.43T

Formula: L(unfold length)=A(Outside size)+B(Outside size)-K(K-factor)

None-90° bend unfold according to the neutral layer, the distance from neutral to sheet inner side is T/3, inner R can refer to the above chart.

V-die width is 6-8 times the plate thickness

None-90°bend = 180°- Angle/90°*Deduction

The deduction is 1.8 times the steel plate thickness and 1.6 times the aluminum plate.

For plate under 2mm, K-factor is 0.432, R=plate thickness, unfold size can accurate to 0.05.

Generally, when design the sheet metal parts, the min inner R=thickness/2, if less than that, the grooving (V-cutting) will be required to solve the problem.

Further reading: